-

Printed switches for ALSA

02/05/2019 at 18:00 • 2 commentsCyndy and I have been working toward a single-finger tactile switch for her clients to use, and a while back I printed and shipper her a design by Davross: https://www.thingiverse.com/thing:3211154

![]()

I got some feedback today, and will be working on a revised button that has different cord options and a lighter activation force!

-

On-site LipSync setup in Auburn, AL

09/17/2018 at 21:54 • 0 commentsThis past weekend I drove down to Auburn to help with installing the LipSync for my first user, Mr. M! It was busier than expected, as I accidentally scheduled the trip for a home game of Auburn vs. LSU.

I had pretty minimal coordination with Cyndy, my contact at ALSA, mostly due to my lack of time outside of work. But we were able to set a date and I got up Saturday, packed my car, printed some directions to Auburn, and hit the road! The drive down took about 4 hours, and then I spent an additional hour lost inside campus, just trying to find the right neighborhood among the teeming masses of people present for the football game.Finally I found the house. Cyndy was already there so we unpacked and got to work. The main order of business was figuring out how to mount the LipSync to Mr. M's wheelchair, which proved surprisingly difficult.

The first candidate was Loc-Line, a new (to us) product Cyndy had found which is a snake of linked plastic segments that snap together and create a fairly rigid arm.

In true "if you have a hammer, everything looks like a nail" fashion, I printed a few pieces to test making an adapter from loc-line to the LipSync, only to discover that the weight of the LipSync was too much for the length of loc-line required. A LipSync can be supported by about one foot of the stuff, any more and just the weight of the mouse will drag it out of position.

We worked with a few other mounting ideas before settling on a flexible webcam arm purchased online. It had less than ideal clamps to mount to the wheelchair, but would work decently well on a desk. Finally, Mr. M was able to take the LipSync for a test drive!

I didn't take very many pictures, as I was essentially a stranger in Mr. M's home, but I did write down notes from the trip so that Cyndy and I can iterate and improve on the experience.

Problems identified:

- We didn't have a good solution for mounting the LipSync. In my testing I had just held the LipSync... With my hands. Pretty glaring omission on my part.

- The LipSync does have a learning curve, and I need to find the best way of training someone new on using it to minimize frustration.

- The LipSync needed some effort in configuration. Windows 10's default mouse acceleration profile was bonkers, and we had to tone it down to make the mouse usable.

- The mouthpiece filter needs to have the extra locking piece. It popped off the LipSync within the first few minutes of use. We wound up supergluing that one together, with a promise that I'd fix it properly later.

- The LipSync tended to move the cursor while Mr. M was trying to click. Perhaps a firmware change - one that locks out the first second of movement in case the user is trying to click - would help.

Successes:

- The i3Mk3 survived 4 hours in the car! I was able to drag it out of the passenger seat, set it up, and start printing pretty much straightaway (after a Z-Calibration). My old printer would not have handled travelling so gracefully.

- We were able to get everything together enough that Mr. M was using a LipSync! There was a reasonable chance that we'd be stuck at some hurdle and have to leave without reaching that milestone, I'm so glad we made it!

- After trying out the LipSync, Mr. M's testimonial is that it was easier to use than an eye tracker. That's a pretty positive review!

Takeaways and future improvements:

- Cyndy has ideas for more AT devices we can print. I'm very excited to help with developing those!

- Having a wireless LipSync variant is the future. I need to investigate if the next gen Adafruit "Feather" based LipSync will have bluetooth.

- When installing a LipSync, it needs to be 100%. There's not really a "eh, good enough" use case, because of the difficulty involved with just using the device to begin with. I need to get the mounting and user experience (software setup) really tuned in, otherwise the LipSync on its own isn't useful!

-

First LipSync user and better 3D prints

09/06/2018 at 18:49 • 0 commentsI have a user! The Alabama chapter of ALSA has a client who is interested in trying a LipSync to use. I shipped the unit ahead of time today, and I'm driving down to help with installation on the 15th!

---------- more ----------Since this is my very first hand-off of an AT system I told the user he'd be a guinea pig. hopefully there isn't too much to iron out, but just in case I'm going to be visiting in person to support his AT specialist. I'm ecstatic to be finally sending something out; I hope that this new mouse serves the user well and that I can keep making AT for more people.

Another exciting development can be found in the picture above too. That case is PETG! I've gotten my new i3 printer pretty well dialed in with PETG, and I was able to print a full LipSync housing. With that success I turned around and purchased a few more reels to use.

-

First LipSync Working

07/19/2018 at 17:30 • 0 commentsI've been slowly working through the BOM for LipSync and gathering parts. Once enough items had arrived, I started putting together the first PCB. And just this week I was able to plug the LipSync into my laptop and control the mouse with it. It works!

---------- more ----------The overall quality of LipSync -- from BOM to build documentation, to the design itself -- is superb. Very rarely do I encounter things that are as obviously well crafted with so much attention to detail. I'm excited to begin working on the other two (I bought parts enough for a set of three), but unfortunately there's been a snag with distributing them. It looks like my point of contact at the local UCP branch has moved, so I'm in a holding pattern until I find someone new who can help me pair AT devices with people who can make use of them.

Unfortunately that same absence means I also don't have anyone to give me direction in the long-delayed revision of Clunke. I'm going to do what I can on my own to keep moving things forward, but sooner or later I really want to be back to collaborating with others.

-

PCBs and mouthpieces arrived

06/16/2018 at 20:23 • 0 commentsThe LipSync PCBs arrived!

---------- more ----------I'll clean up the nibbles on the edge with a dremel later on.

There's a hiccup with the LipSync BOM. Several of items are sourced from Qosina, which strictly deals only with companies and not individuals. One of those items is a mouthpiece that I simply cannot find anywhere else online. Eventually I'd like to set up purchasing through my local makerspace, but the organization is dealing with some problems right now and I don't want to add to the stress.

Luckily I was able to find an AT devices company that sells a luer-lock compatible mouthpiece, which I'll use for these initial LipSync test units. Those mouthpieces also arrived:

I'm going to leave them in the sealed packaging until they're ready to be installed.

-

LipSync PCBs have shipped

05/18/2018 at 06:11 • 0 commentsThree LipSync PCBs are on the way!

![]()

I'm still scouting out the rest of the hardware, and have found a roadblock: some of the parts are listed on Qosina, which does not sell to individuals. Even worse, one of the parts (a mouthpiece) simply isn't available anywhere else. The closest thing I could find were AT mouthpieces made by Quadstick, so I bought a few of those. Eventually I'd like to try getting my local makerspace involved (yeah, right) and use their tax ID to purchase from Qosina.

-

AT Kit Printing

05/16/2018 at 04:57 • 0 commentsIt's been a little over half a year since my last progress here. I wish I hadn't taken this break from my hobbies, but at the end of last year a good friend of mine went into a coma and then passed away. It's been a struggle to just go through the motions for a while.

I'm back now though. Hopefully we'll get Clunke sorted and to a usable state soon.

---------- more ----------Finally got around to donating the HaD prize money from last year (should have just done it immediately, I know):

![]()

Printing PET-G is still holding me up, so I'm going back to PLA for now, and have ordered a new, nicer 3D Printer that should arrive later this summer. I'll try printing PET-G again on it. In the mean time, I've started printing parts from the Low Cost AT Kit to offer, as well as begun making a test run of LipSyncs. I've followed Neil Squire's email list for a time now and am a huge fan of what they're doing with the MakersMakingChange project, so it's exciting to be making some items from their catalog.

![LipSync Printed Parts LipSync Printed Parts]()

LipSync printed parts ![AT Kit AT Kit]()

AT kit printed parts I think that's it for now. I haven't worked up the nerve to try getting back in contact with UCP, but I'll try to send them an email sometime soon.

-

200W Print Bed Heater Results

10/19/2017 at 14:27 • 0 commentsI finally determined that the 100W heater I had just couldn't keep up with the demand of printing at 80-100C, so I purchased a silicon 200W replacement and got it installed.

---------- more ----------Removing the old heater's tape proved to be pretty time consuming, but eventually most of it came off:

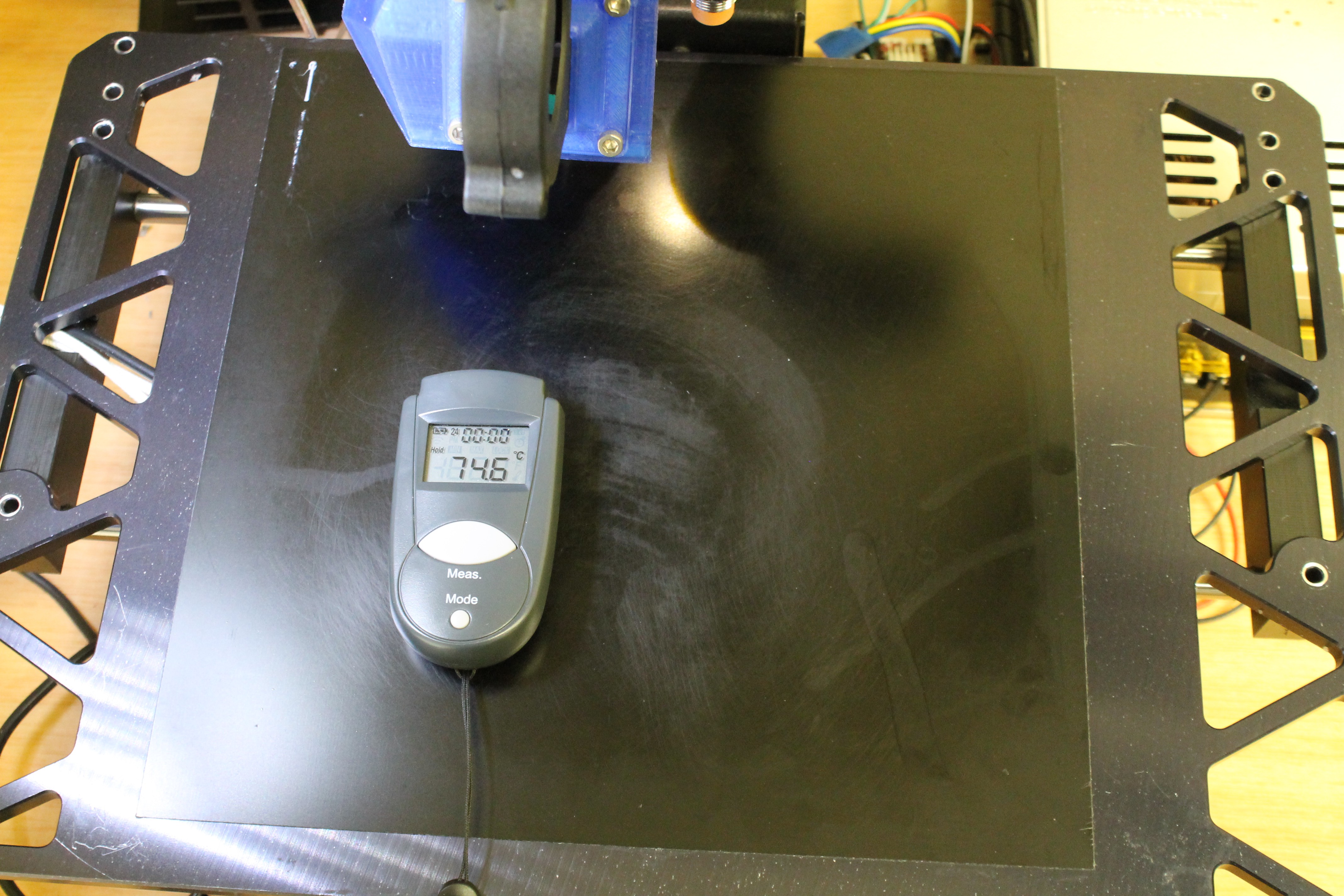

But then it turned out that the new heater's temperature sensor was very close to the heating element, and didn't really tell me what the bed temperature was. Here is the surface temp while the heater is at 90C

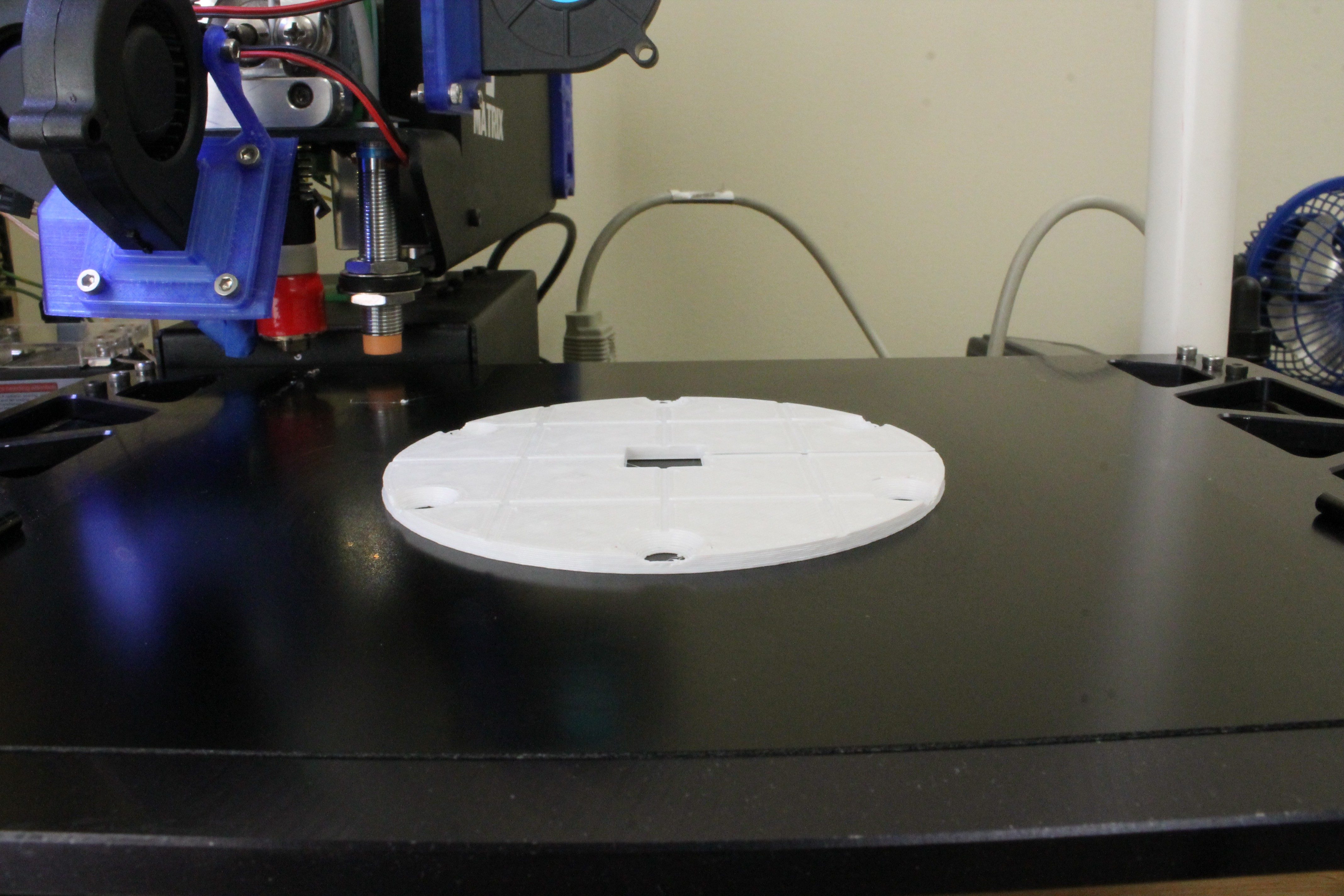

So with that offset taken into consideration, I tried printing just the first few layers of a button base:

And it WORKED! The part printed very nicely, and we can finally, finally move on to printing the parts for user testing.

Coincidentally, the Hackaday Prize (and my own go/no-go evaluation) is about to wrap up and I'm nowhere near where I wanted to be by now. That's the frustrating part about setting abstract deadlines: meeting them can become more of a gamble than a challenge. Despite not having conducted the user testing that I want, at least I'm back in a position where it can happen, which is a lot further along than I was a month go!

-

Still Tuning

10/12/2017 at 00:13 • 0 commentsThe PETG arrived!

---------- more ----------And I'm still fiddling with the print settings:

I bought a heating plate with twice the power draw as the current one, hoping that it helps get the bed temperature high enough to make this PETG stick.

-

PET-G Tuning

10/09/2017 at 15:45 • 0 commentsPrinting with PETG is turning out to be pretty difficult. Every time I think things are tuned, something new goes out of whack and I'm back to square one.

---------- more ----------Right now prints are barely holding adhesion to the printbite bed surface, and I'm fighting weak layer binding as well. It looks like a new fan shroud might be in order, since too much cooling can cause both of the current symptoms.

An important note here is that I've caused myself some unnecessary heartburn by changing multiple variables at once. I installed Printbite on the build plate just a few days after I switched to printing with PETG, which makes evaluations of how well Printbite is working and context against the previous surface difficult to get. Granted, I made the sudden switch because initial PETG prints on the older surface were going poorly, but I didn't give it enough time to know whether or not that was because of poor tuning or just incompatibility.

Christopher

Christopher