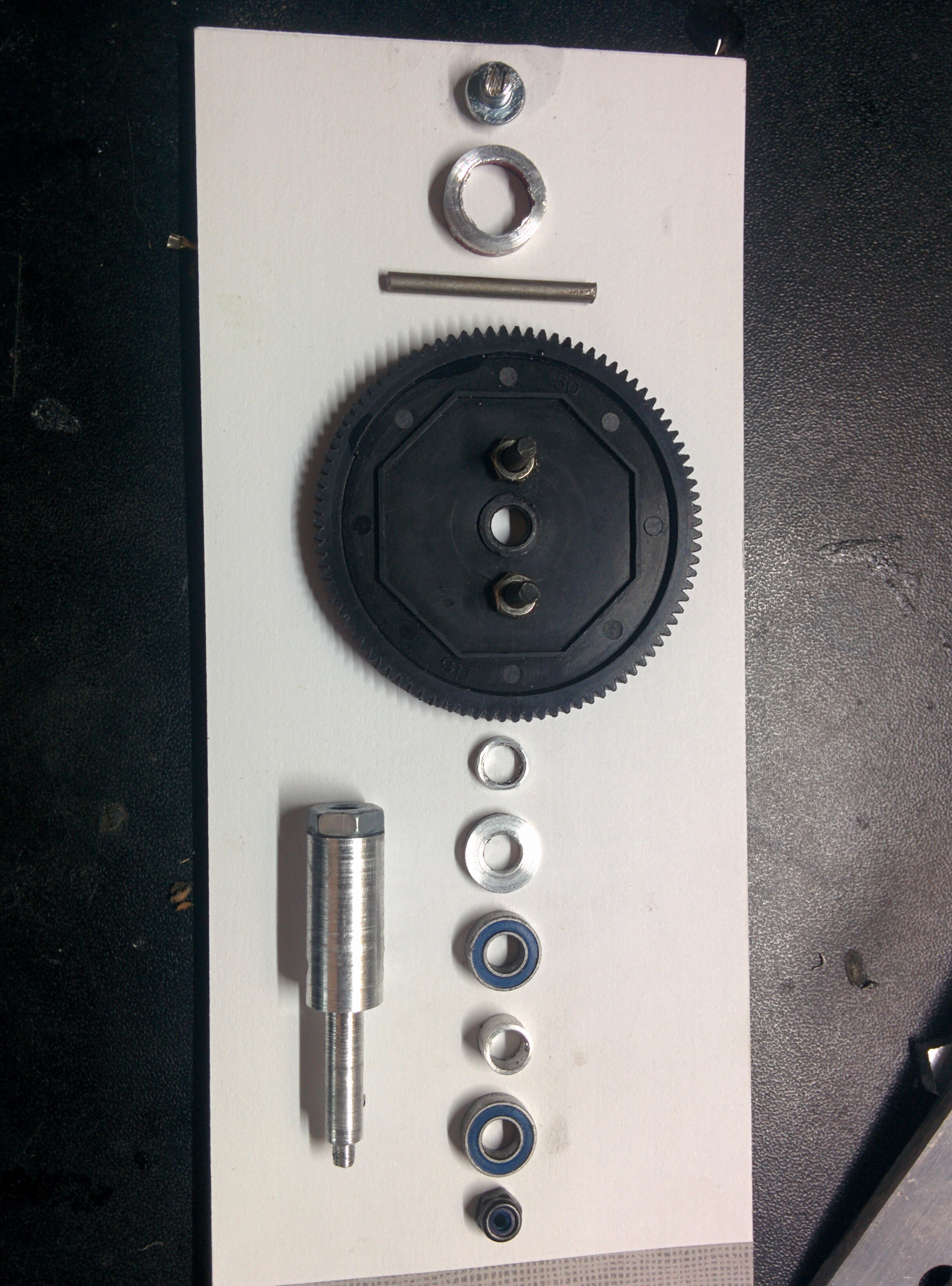

To gear down the motor I am using a two gear system with a steel pinion and plastic spur gear. The broadest range I could find was 12t and 89t respectively, bringing the reduction to 7.4:1. Adding another set of gears would easily bring it to 10:1, but this also increases size and adds failure points. Using round aluminum bar I lathed an adapter to go from the 5mm motor shaft to 1/8in pinion internal diameter. The same metal was used to make a spur gear / prop shaft. It's held in place by two seated bearings that attach to the motor mount. Various spacers and pins make sure that everything stays in place and power is transferred from the motor to pinion to spur to prop. The entire assembly fits inside the "hub" of the prop as to create as little drag as possible.

Note: Unfortunately my lathe's motor decided to quit while I was working on another project, so it's going to take a while until I can make new parts if these don't work.

Dominic

Dominic

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.