hello

Lets all put our heads together and make this true.

I have sketched a few ideas on what this printer should do:

-create traces

- this could be achieved with standard copper strands from electric cables - flexible enough to be shaped in complicated shapes

- cheap -people can buy feets of cable and peel them,then spool each strand - cheap but tedious

-pads

- with some work can be made from the strands

Adhesive - very strong - only a very thin layer required,that dries slow and the bond is strong after curing

Longshots :

- vias

- multiple layers

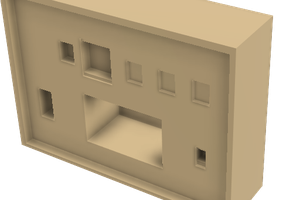

Ideas so far

Substrate - well...a laminate of sort coated with contact adhesive in very thin layer

End tool for depositing strands

- thought of a syringe needle with a flared round tip or a small roll at the end

- plastic stopper to keep the strand still to make an angle

- cutting tool - should be sharp and thin,also not mess up the traces that are cut

- narrow - to avoid cutting into already laid traces

- fed through a bowden cable?

Software

- a 3d printer slicing model should do,modified to make only 1 slice/layer

- a script that reads common EDA files and calculates no. of strand to be aligned for wider traces

Issues so far:

- soldering not ruining the bond between substrate and traces

- aligning strands next to each other with good electrical contact

Goals

full open source and for modifyng

under 100$ complete cost

Since one man can only view a problem from one point of view,that is why i am trying to make this a community effort.

muzi

muzi

Alain d'Espaignet

Alain d'Espaignet

Films4You

Films4You

Dustin Sysko

Dustin Sysko