Let's cut to the chase and figure out how to treat an ultra low noise reference like MAX6126.

https://datasheets.maximintegrated.com/en/ds/3623.pdf

It has to be determined experimentally how much improvement is needed here in the context of other noise contributions. One can start out with maximum capacitance and investigate individual noise contributions one by one.

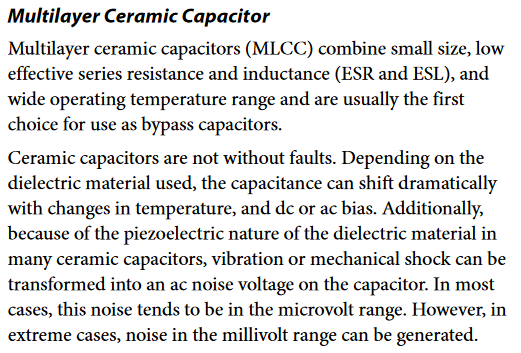

It has to be determined experimentally how much improvement is needed here in the context of other noise contributions. One can start out with maximum capacitance and investigate individual noise contributions one by one.capacitor selection

Solid electrolyte tantalum capacitors are more stable in that regard but exhibit higher leakage current.

Solid electrolyte tantalum capacitors are more stable in that regard but exhibit higher leakage current.

http://www.analog.com/media/en/technical-documentation/application-notes/AN-1099.pdf

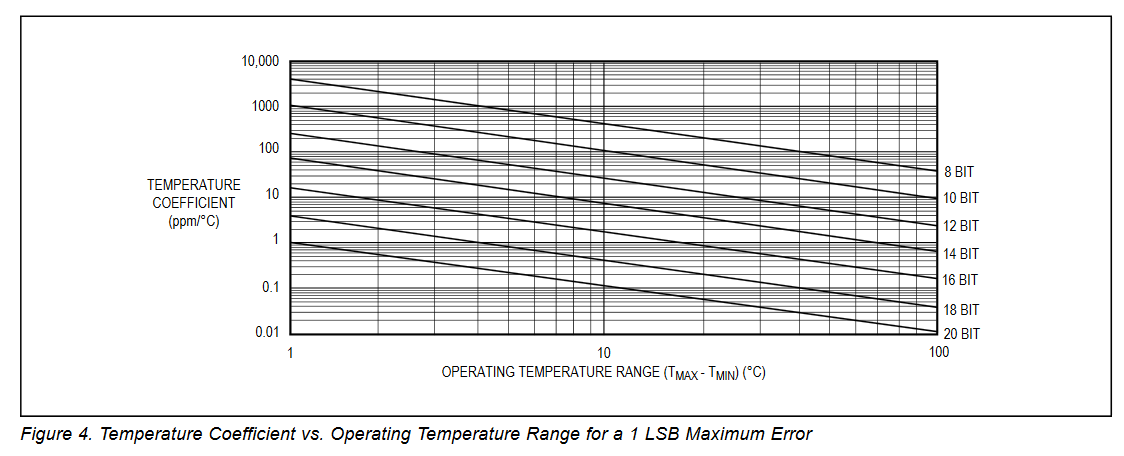

temperature compensation

It will be annoying to add a temperature sensor to the load cell, e.g. by glueing an NTC to the element and judging by our previous set of experiments the single point load cell type does not seem to be overly sensitive to temperature variations and satisfies temperature stability requirements without further compensation and software calibration. Absolute measurements however are degraded by reference drift:

An HX711 next to substantial heat sources (such as the NodeMCUv2 board with 5V-3.3V LDO) in an enclosure will likely see a 10 .. 20 K temperature rise. Additionally the on-board DCDC might contribute with lateral heat diffusion when in operation.

Counter measures include distance, thermal isolation slots and use of software calibration based on digital temperature sensor readings, e.g. from

TC74, AT30TS74, TMP100 (cheap to expensive)

temperatue effects

Once again it's easier to not cause disturbances than to deal with them later on.

But to quote DaveEvans on temperature calibration ( https://forum.arduino.cc/index.php?topic=365107.0 ):

I'm not especially happy with the results. Subsequent tests showed that it improves accuracy somewhat, but not as much as I'd hoped.

Once more we'e left with the need to perform more experiments to see where the 80-20 trade-off is. Maybe we're already there, or maybe integrating HX711 and subjecting it to heat and switch-mode converter noise will be a big deal.

next up we'll finally use HX711 data to determine the effects of PNP transistor selection, output bypassing, reference bypassing and power supply ripple rejection.

helge

helge

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.