UV Lightbox

Digitally controlled UV lightbox for PCB manufacturing

Digitally controlled UV lightbox for PCB manufacturing

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

As I wrote in my last entry about the Lightbox, I ordered a new display. It is arrived more than three weeks ago (I was on vacation, therefore wasn't able to write this entry).

Tested it:

It works, visible, but still dim a bit. I'll keep it until the enclosure finished. We will see, if it is good enough when it is mounted in it.

I built the new display panel in the night:

I tested it. Works...

...but I can't call it a complete success. As you can('t) see the display is so dim, that it is almost invisible.

I know the reason why. It dated back in a few years. Let say five years ago, I wanted to build something. I bought a LED display and some drivers to it. The build didn't happened. To be honest I don't even remember, what was it. The LED display left in my drawer.

When I started to build this lightbox, I was thinking, that is a good idea to use the display from the drawer. It is a HDSP-B09G display from Avago (formely Agilent (formely HP)). As I figured out this is a real old design, with low intensity LEDs.

Yesterday when I realized, this is a crap, I started to search something with the same pin configuration. The result is NULL - except Avago's minimally newer HDSP-B03E. I'm not confident, that this one is really brighter.

So I've two choices:

1. Try to buy and use the "brighter" Avago

2. Redesign the display once more, and create a new board (Nooooooooooooo!!!!!)

So I order the Avago display, and we will see.

I was able to etch, drill the new PCB for the display. Unfortunately I had not enough time to populate the board.

I almost finished the design of the new enclosure. I've turned the lighting boards from the bottom to the top, added two drawers. The upper one keep the board during the processing, the lower one is just a drawer for copper clad boards - I'll store them there.

Now I have to disassemble this design into its components to be able to manufacture. The question what I can't answer right now, if I'll cut the pieces myself, or order it somewhere.

On the side I redesigned the display PCB. I hated the original one, but when I worked on this project (long time ago), just left it as is.

The new is much better layout, not so tiny pads what is almost impossible to solder, more space between, the buttons, etc.

This project is still lying around in my workshop. The biggest problem I had with it, what kind of glass/plexy/etc. should I use on the top of the LEDs to be able to allow the UV light to go through it. Even I scored a UV integrator on the eBay (for ~$20) to be able to measure the performance of the LEDs through the chosen material.

On a day just pop into my mind that I was thinking in the wrong way all the time.

What if I turn the whole thing upside down?

1. I don't need any material between the LEDs and the mask.

2. When I put the mask on to the work piece I can see the alignment, not just guess it.

Now the next step is designing and building a new enclosure. Even I went further with the thinking. I put the whole thing into a flat closed box (without an lid what can be opened) and add a drawer for the work piece. This way it occupies less space, because I can put things on the top of it.

In this project log I'll build the whole construction from the beginning. To understand, I started to plan this project almost a year ago, when I realized the possibility to create soldering mask at home. I don't need UV for my PCB trace manufacturing because I'm using toner transfer method for it.

The construction has the following elements:

Light module: One of my major concern was, that I didn't like to etch or order a 20x30cm PCB. Etching it, drilling it is a pain. Ordering on the other has high cost. So the design is a little bit tricky. The light module become modular. I choose a 10x10cm size. Ordering 10pcs of 10x10cm board from seeedstudio cost me $25. It is affordable for this project and I use six of it to achieve the required 20x30cm size. I wanted to be able to control the current flow of the LEDs almost individually to be able to create equal current distribution. It lead me to not use parallel connection between the LEDs. Use certain amount of it in series, control the current flow of this serial lines and connect this regulated lines in parallel. This setup has the advantage to be able to equalize the current, and it has a two drawbacks: Relative high operating voltage and high number of control elements (darlington arrays and trimmers in this case). The board of the module design trick allows me to connect any number of modules in series. The module has three possible configuration:

Upper module:

Contains no control elements. The last line of LEDs are put in the board rotated by 90 degrees. This configuration connect the anode of the top LEDs together. This will be the high side of the voltage supply. This board has no connectors on the upper side.

Middle module (finally it is not in this configuration):

Same as the Top module, without the LED rotation and upper side connectors.

Low side module:

Same as the middle module, but with all of the control elements included, and the lower side module connectors are changed to the power and control connector.

Here is the schematic:

The PCB design:

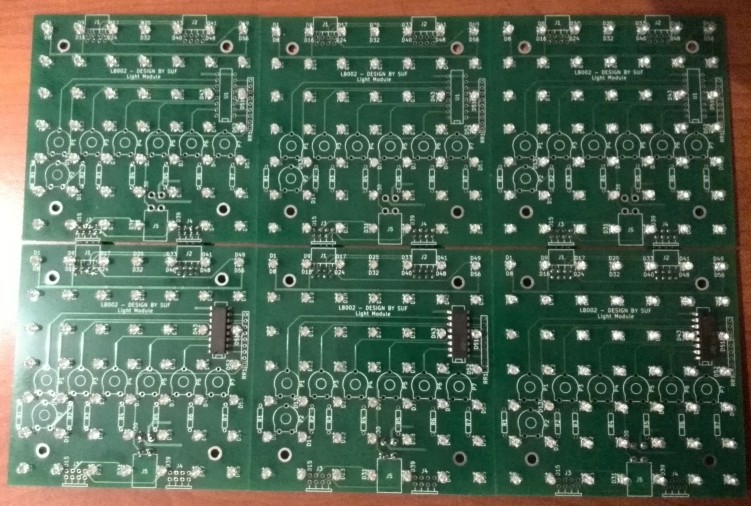

The board back from seeedstudio:

The partially populated boards (some resistors and the trimmers missing):

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

I am from indonesia and interested in project can you help to send design layout pcb uv lightbox this to me, i want to make it for his attention i thank you very much