The heated bed was mounted on all four corners. There was provision for a three-point mounting system (to aid levelling) but I figured the borosilicate glass plate would help keep things level. I used the springs provided in the kit to mount it the standard adjustable way. Again, tapping a thread into the aluminium was very neat. Bulldog clips were used to hold the glass to the bed. The heated bed setup was a pretty standard affair for 3D printers.

Heated bed, borosilicate glass and cork placemat

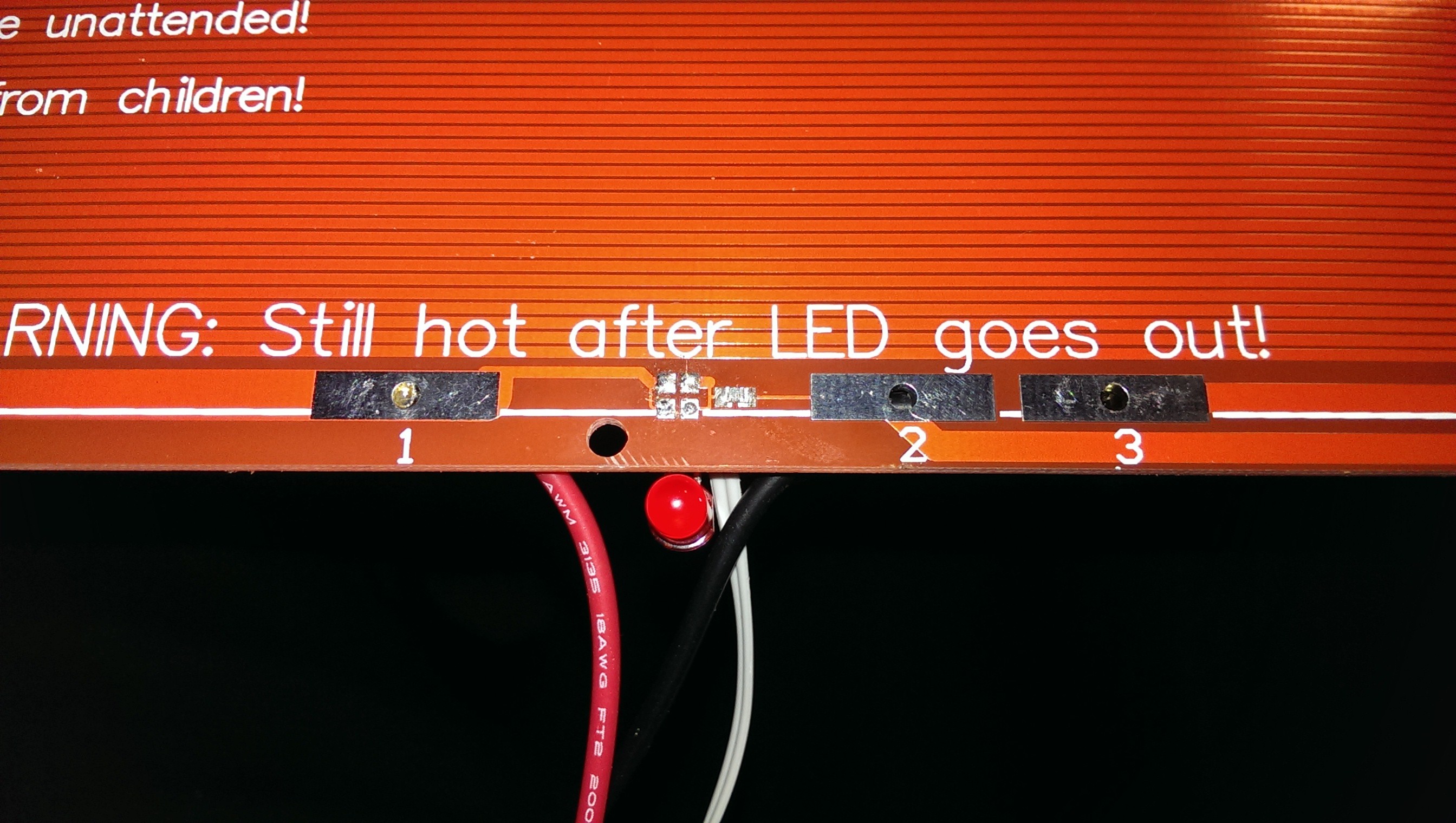

There was a small SMD LED soldered to the edge of the board to show when the power was connected. Unfortunately, it came soldered to the wrong side of the board (I know the MK2B heated bed can be used either way up). I managed to ruin the LED trying to desolder it so just replaced it with a regular sized LED and new resistor.

Oops!

To improve bed adhesion, I used diluted PVA in water. The solution was spread onto the glass with a small paintbrush while the bed was warming up. When the bed was levelled accurately this resulted in excellent first layer adhesion. Corners of parts stuck to the bed throughout the print and I had zero warping - even on big parts. Parts were nearly impossible to remove until it had cooled down to room temperature. Once cooled, prints would pop off easily. Occasionally a thin wedge (razor blade) was required to “crack” it off.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.