The first bearings I bought were cheap LM12UU linear ball bearings. They worked fairly well and were reliable. They did however have some slop and were noisy. I started to strive for more quality in my prints and noticed sometimes there would be vibration lines in the surface finish. This was mainly due to the slop in the bearings.

When I upgraded to magnetic ball joints I also tried to upgrade the linear bearings. I thought that longer bearings would help with the slop and result in more rigid mechanics. I bought a set of 57mm LM12LUU long linear bearings to try.

The bearings made a huge difference to the rigidity of the delta mechanism - so huge that they introduced even more resonance! They were also quite heavy so some of the benefit was lost having to print at slower speeds/accelerations. I also noticed the motors were running hotter as the friction was higher.

Super rigid

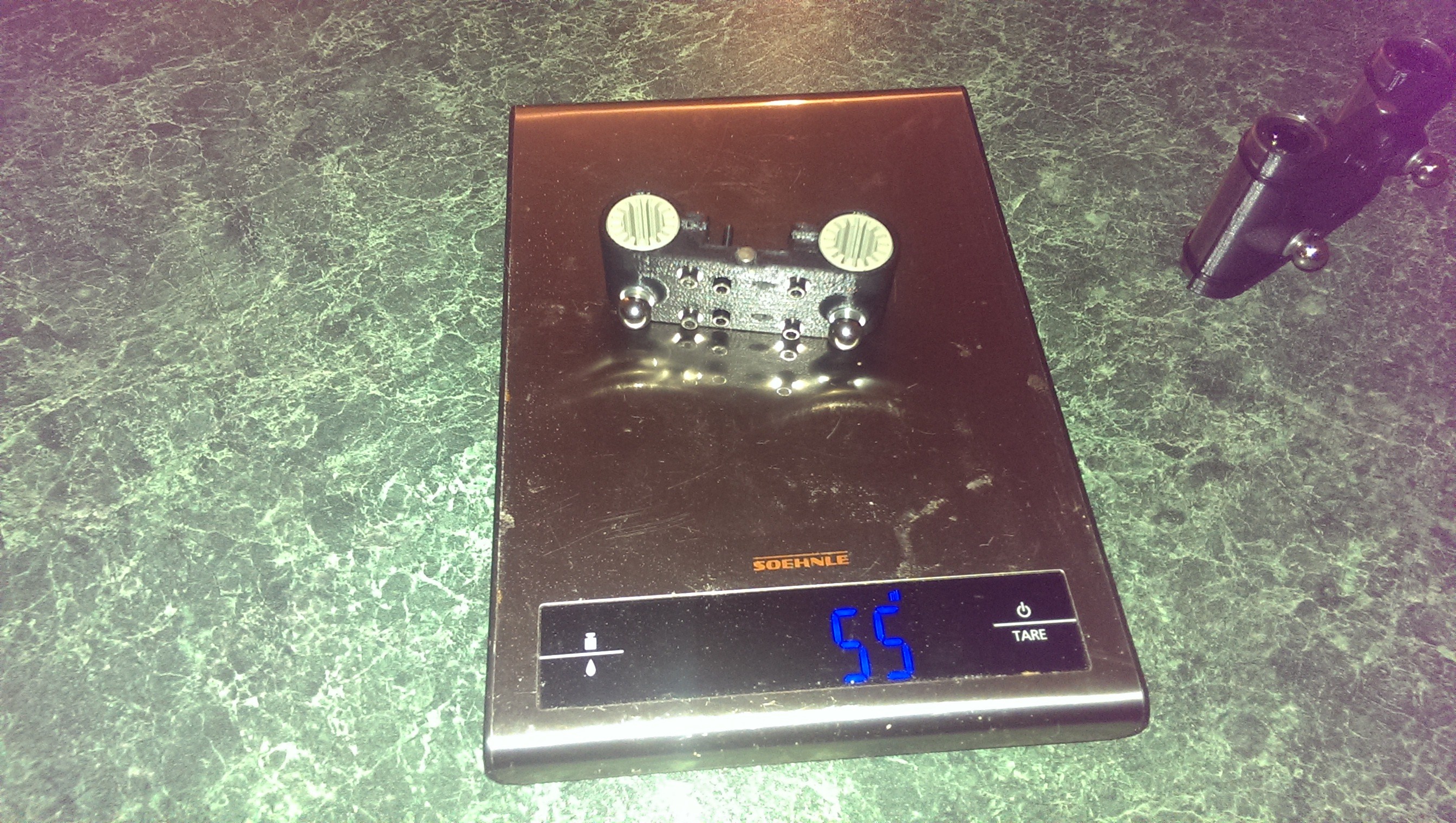

Igus Drylin Polymer bearings were becoming quite popular so I bought a set to try. They require a certain amount of pre-loading so I re-designed my sliders to incorporate a clamp mechanism. Here are some terrible quality photos of the weight difference between the 57mm LM12LUU sliders and the polymer bearing sliders:

145g

55g

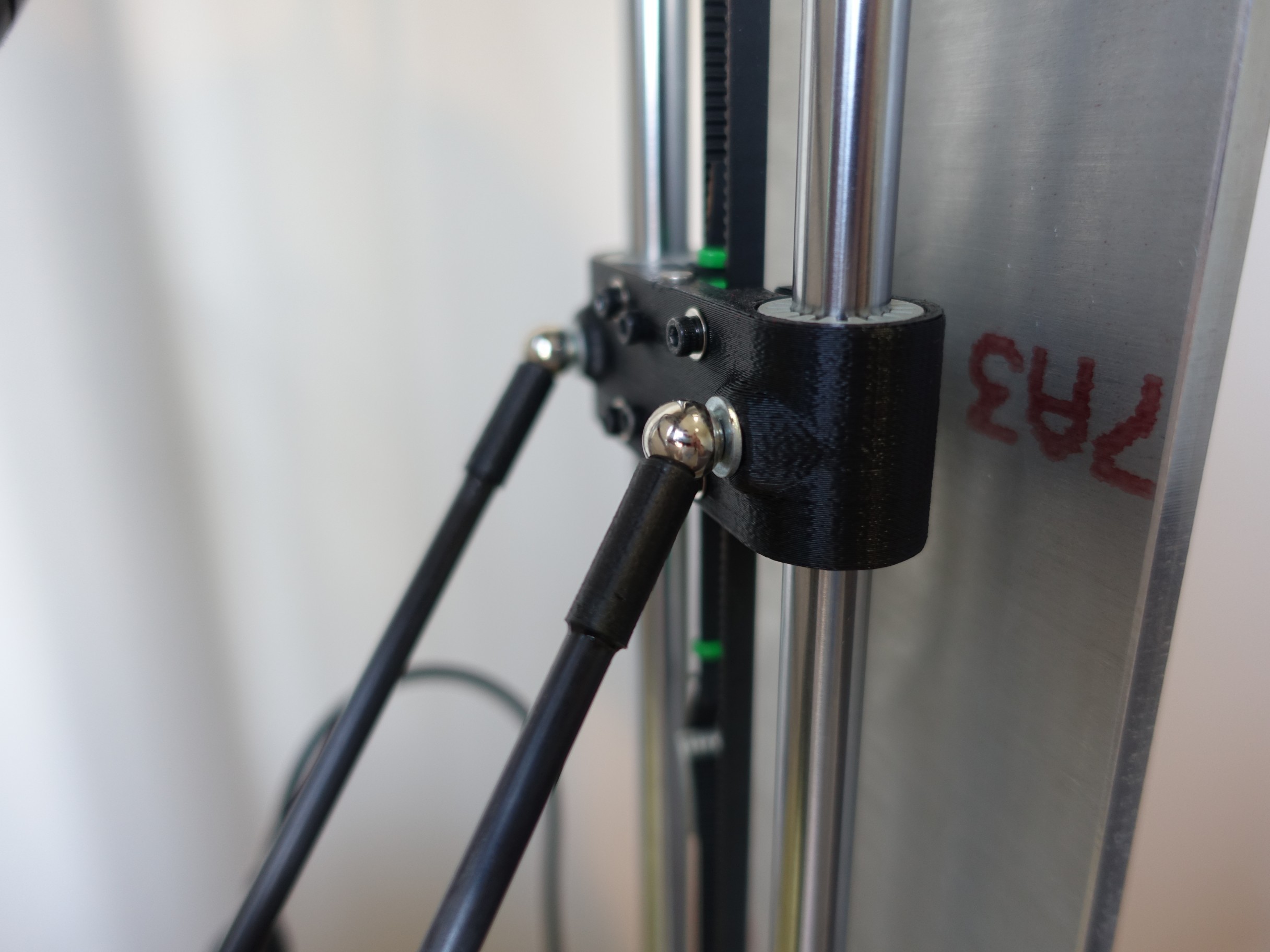

They are super quiet, light and very smooth, though they still have a bit of slop. I’ve deemed this an acceptable compromise. You can hardly hear the printer while it is running!

New lightweight silent sliders

The belts loop over the two protruding bolts. Also notice the captive nuts.

Very neat

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.