This project started with the construction of a finger with the idea that I will work my way up the hand until it is a functional prosthesis or humanoid hand. The hand is to be constructed out of 3D printed exo-skeleton and silicone cast fingers all pneumatically controlled. This log documents how the finger has been created, but not all the many iterations before arriving at a reasonable close finish, refinement is still possible.

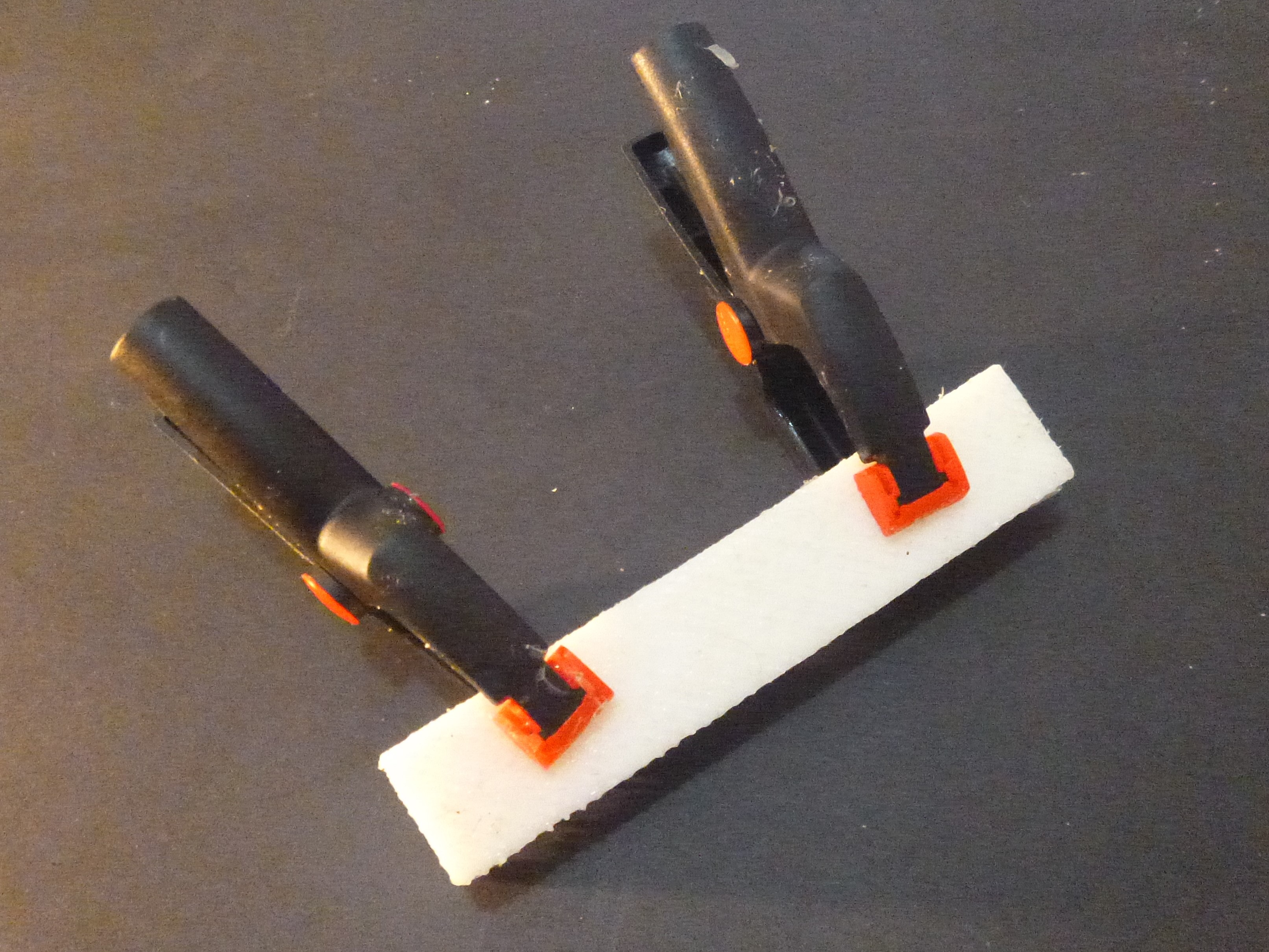

The actuators for a soft robot/prosthetic hand are constructed out of silicone casts from 3D printed molds. The thumb and pointer/ring molds are pictured below with the actuation cavity created by the top mold being inserted into the bottom section located via location dimples.

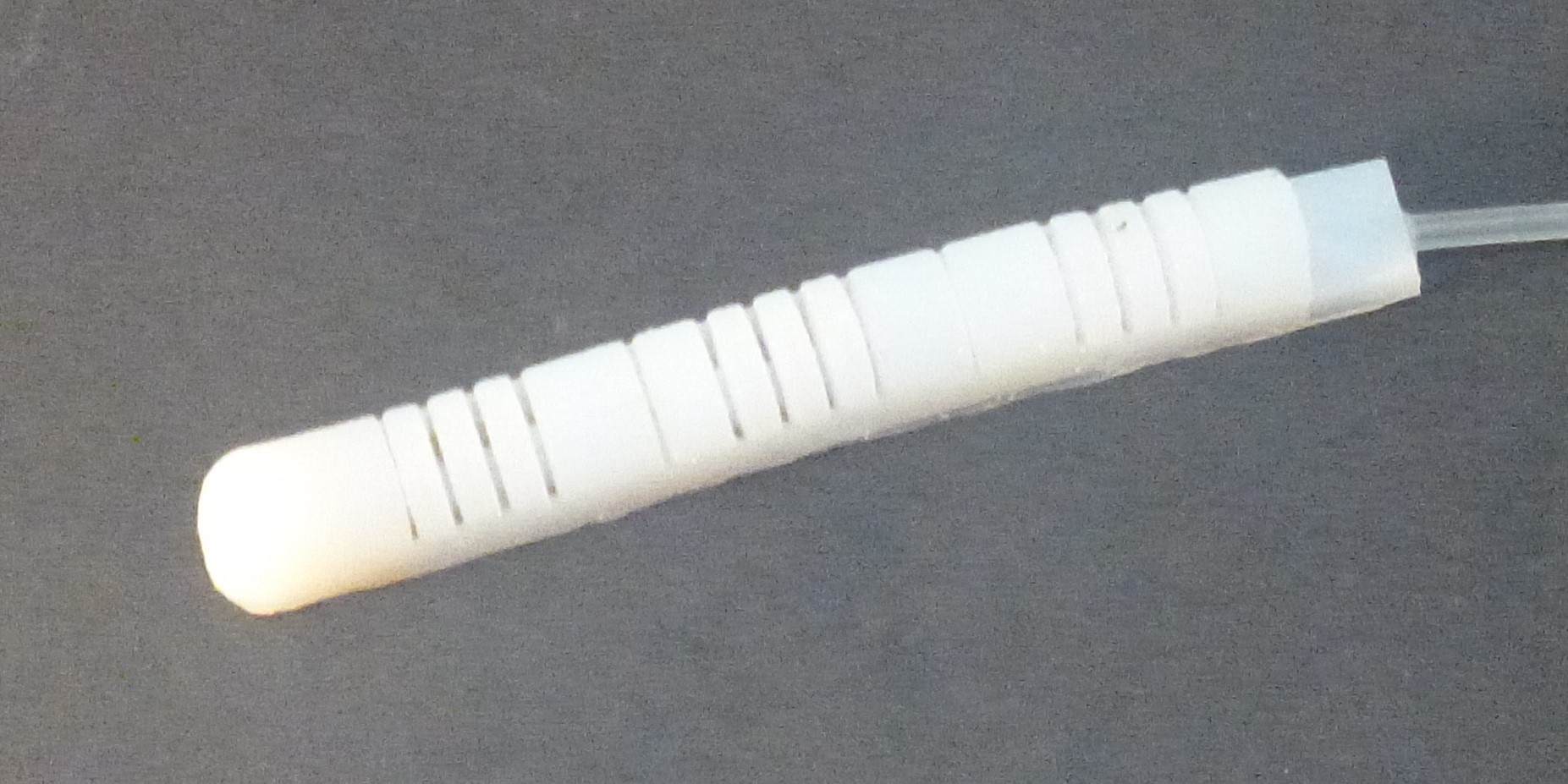

After the mold has being held together until the two part silicone has set a thin, 0.5mm 50A shore hardness strip of silicone is glued by more two part silicone or by specific glue. The harder-than-finger silicone strip acts like a flexure, reducing the bending radii and pressure required to bend the finger.

Above is the thumb with pads on the underside, which will be implemented on all the other fingers.

Nelson Phillips

Nelson Phillips

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.