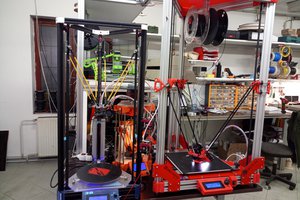

Goal for this project was to create my own 3d printer. I currently have a Makerfarm i3v 12" printer and have been tinkering with it for 2 years. over that time I have really learned alot. and I thought I could do better. After I found out about the Openbuilds vslot and about Corexy kinematics I was sold on my next design.

A few features i wanted my printer to have.

- Print fast

- Full 300mm x 300mm bed available

- Simplified Z probing, without servo (Hinged Bowden E3Dv6)

- Fixed Print bed. (it doesnt move at all) the XY gantry raises and lowers

- very solid construction

- Mesh bed levelling (Marlin UBL Branch under development)

Long term goals for improvement for TitanXY Pro (v2)

- increase bed to 300x600

- change XY motion to using Linear Rails MGN12

Some videos of the machine in motion during testing/adjustment

adamfilip

adamfilip

RenierM

RenierM

BlueFlower

BlueFlower

j0z0r pwn4tr0n

j0z0r pwn4tr0n

Swaleh Owais

Swaleh Owais

That's an impressive choice! A fixed bed CoreXY 3D printer based on Openbuilds rail showcases your commitment to precision engineering and innovative design. It's a testament to your technical prowess and creative vision. The CoreXY system combined with the reliability of Openbuilds rail promises efficient and accurate printing, setting you apart as a maker with a keen eye for detail and a dedication to excellence. Keep up the fantastic work! https://ballsportsgear.com/