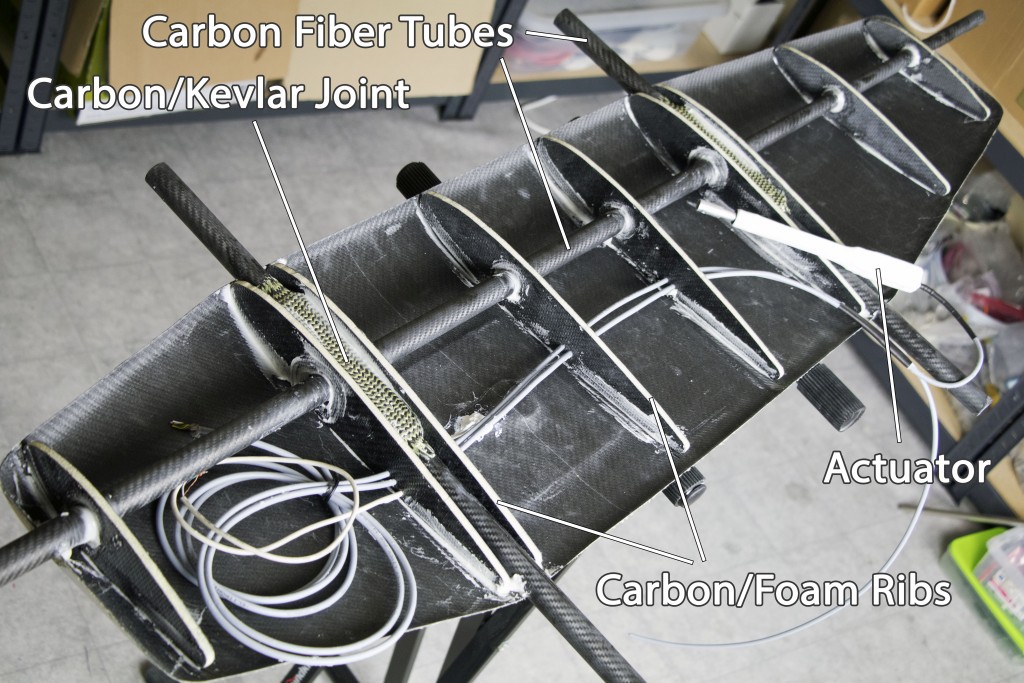

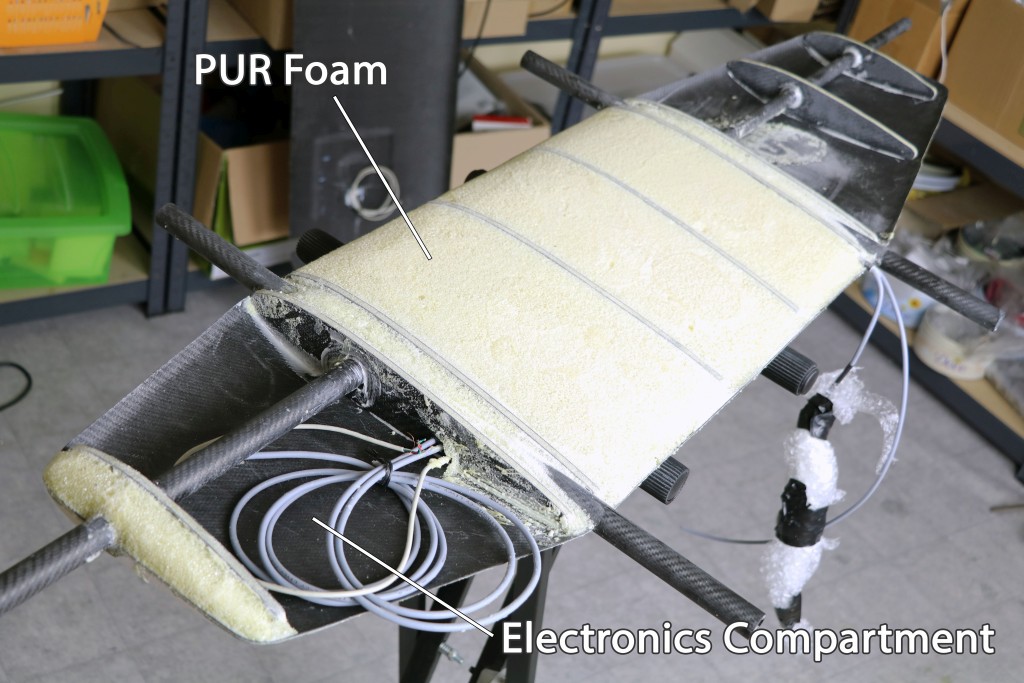

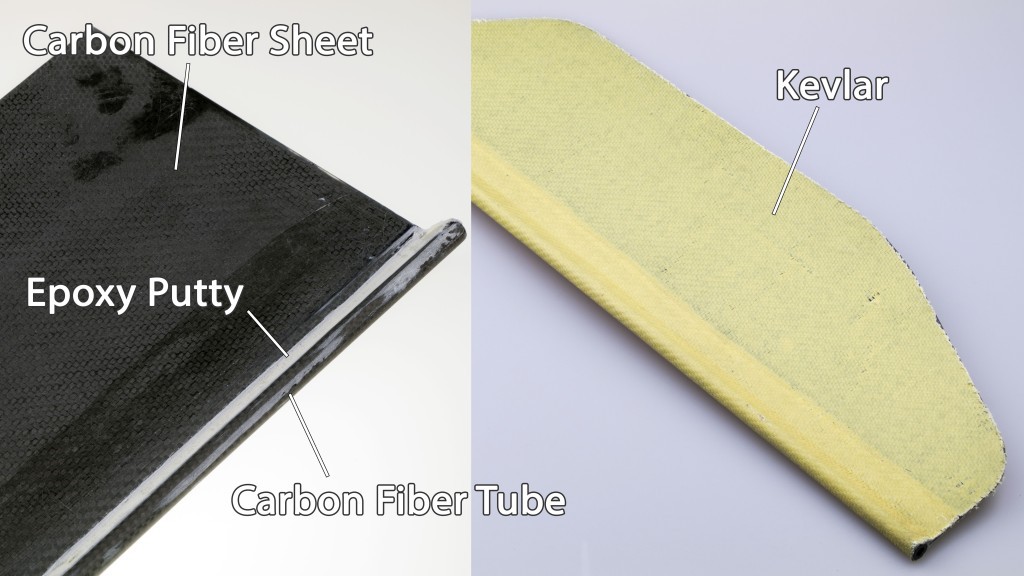

The two resin-infused carbon fiber parts as seen in the project log were joined together with epoxy putty and waterproofed with a fiberglass tape. The inner skeleton makes the sailwing really robust.

Sailwing Control

The sailwing orientation is controlled by a flap that is adjusted by a waterproof actuator. Here's a video how it works:

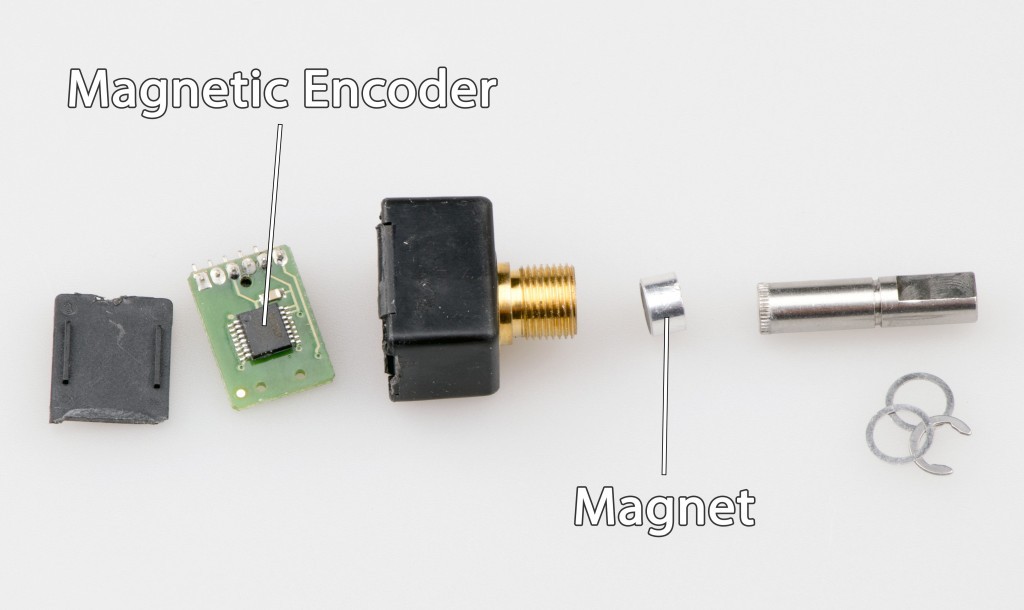

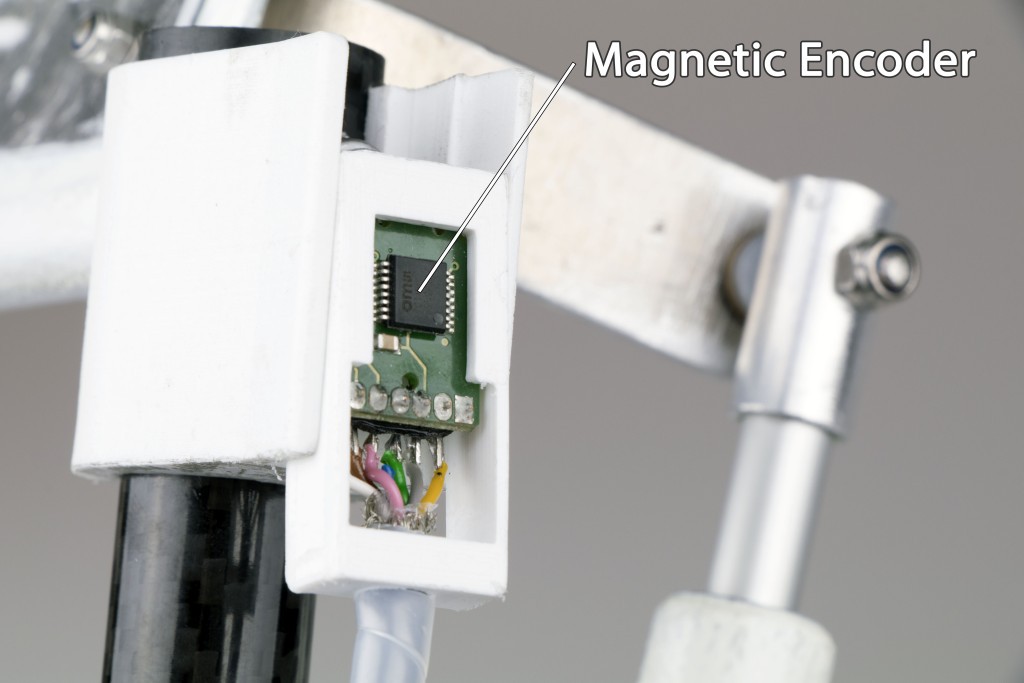

The actuator has a potentiometer that provides a position feedback. However, in my endurance test, the potentiometer was the first thing that failed. I found it's going to be pretty easy to mount a magnet on the end of the flap shaft and use it for a more reliable position feedback.

Magnetic Encoder Teardown

The magnet fits into a standard M6 nut after the nylon collar is removed. I glued it all together with a marine epoxy.

I 3D-printed a PETG housing for the encoder PCB. The PCB will be potted with a heat-conductive epoxy compound.

Finally, here's how the flap was built. A 1-mm carbon fiber sheet is glued to a carbon fiber tube and wrapped with Kevlar.

The next thing to do is a sailwing position sensor that's designed as multiple Hall sensors around the mast. It will act as a backup wind sensor.

Andy Osusky

Andy Osusky

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.