Filament storage science

Beware. Plastic containers are moisture permeable.

Beware. Plastic containers are moisture permeable.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Today I've set up two more moisture penetration tests. One is the same box with the lid sealed using tape. The other is a bit more interesting, and I have great hopes for it.

I've thought on what other container can I obtain for filament storage. I thought of using sauce pots.. but then I decided to try to moisture proof my boxes with alimunium foil tape. Aluminium is absolutely moisture impermeable - even its few-nanometer-thick oxide layer is, which protects extremely reactive aluminium from oxidation.

So I taped most of the surface of the box and the lid. It isn't very important to cover all area with no gaps - for my purposes, based on previous measurement, a 10x improvement is going to be good enough.

Now, all I do is wait. In about half a month, I expect some preliminary results.

-----

UPDATE. Five days since start, none of two containers had gathered measurable amount of water ( < 1 g)

UPDATE2: 3 more days. The one taped with al foil has gained 1 g. The other one hasn't changed. I'm about to draw a conclusion that permeability of plastic of the box is negligible.

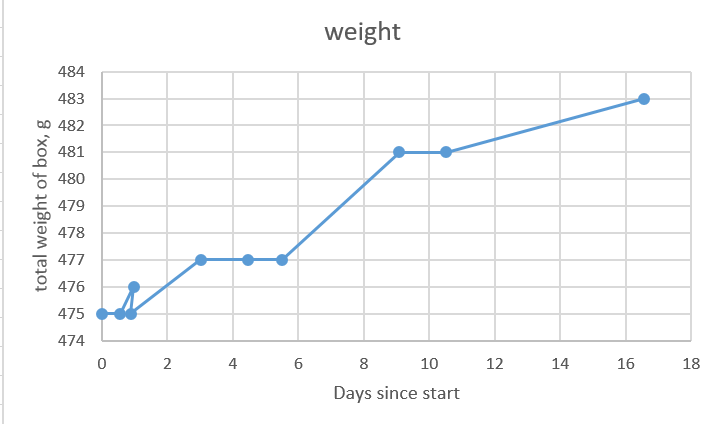

Dried some silica gel. Put it into a box. And recorded weight of the box from day to day. After about half a month, I got enough data to find the moisture permeation rate.

0.52 grams of water per day (24h), at 55-45% humidity of outside air and 18-25°C temperature.

So, if I were to replace silica gel pack every month, I need a pack of 100 grams of cat litter. That's not too much, but replacing silica gel in every box (I have five so far) every month is not something I'd like to do.

Let's take a more reasonable target: replace each half-year (six months). Then, I need to put 600 grams of cat litter. That's half of that bag! There's no way I can fit that much into this box, because it's a rather tight box for a single spool!

BUT. I didn't seal up the lid with tape, and the lid isn't tight at all. So, the experiment will continue with the lid sealed up a bit by tape. Stay tuned, I haven't started this experiment yet.

Now that I have determined the specs of silica gel, time to apply.

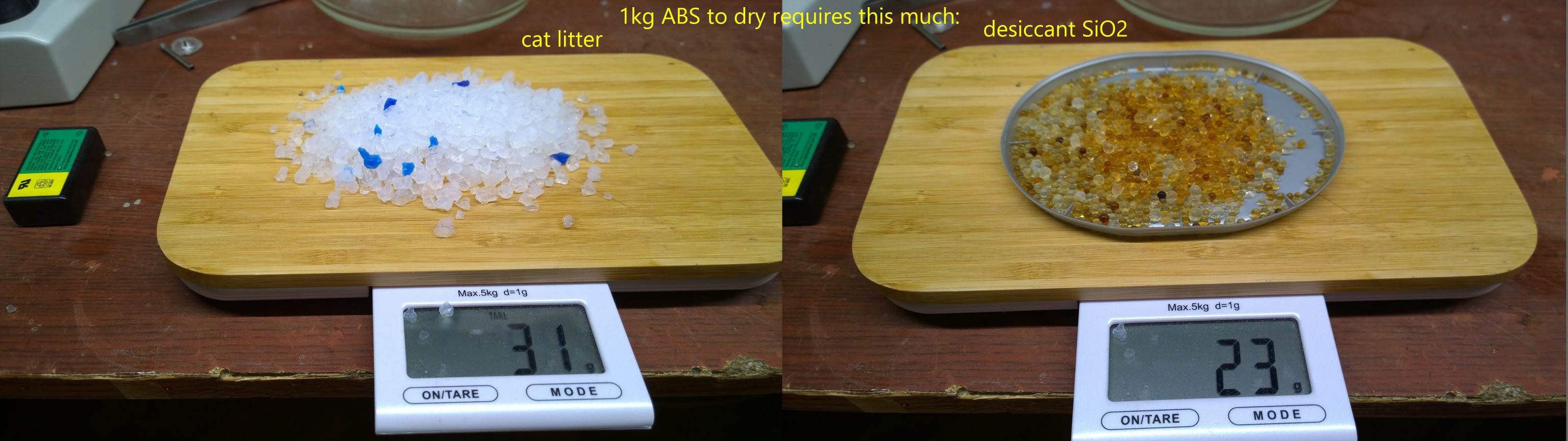

Let's dry a saturated 1kg spool of ABS. ABS water absorption is 0.2-0.4%, as I found from internet.

-> 1kg spool can hold up to 4 g of water. So, I need no less than 27 g of cat litter to dry out one spool. Or 19 g of proper silica gel desiccant.

How much moisture can silica gel adsorb before it's saturated? This can be easily measured when drying it, by weighing it before and after drying.

Typical silica gel, usually used as desiccant:

wet mass = 91 g -> becomes 72 g when dry. saturated = 26% water + 74% dry SiO2 (by weight).

Cat litter silica gel:

wet mass = 54 -> becomes 47 when dry. saturated = 15% water + 85% dry SiO2

So, cat litter silica gel is about twice less efficient by weight than the proper stuff. However, it is also about twice less dense overall, so it takes about 4 times as much cat litter by volume than proper silica gel to adsorb given amount of water.

So, the ultimate figure: To adsorb 1 g of water, I need 6.7 grams of dry cat litter.

---------------

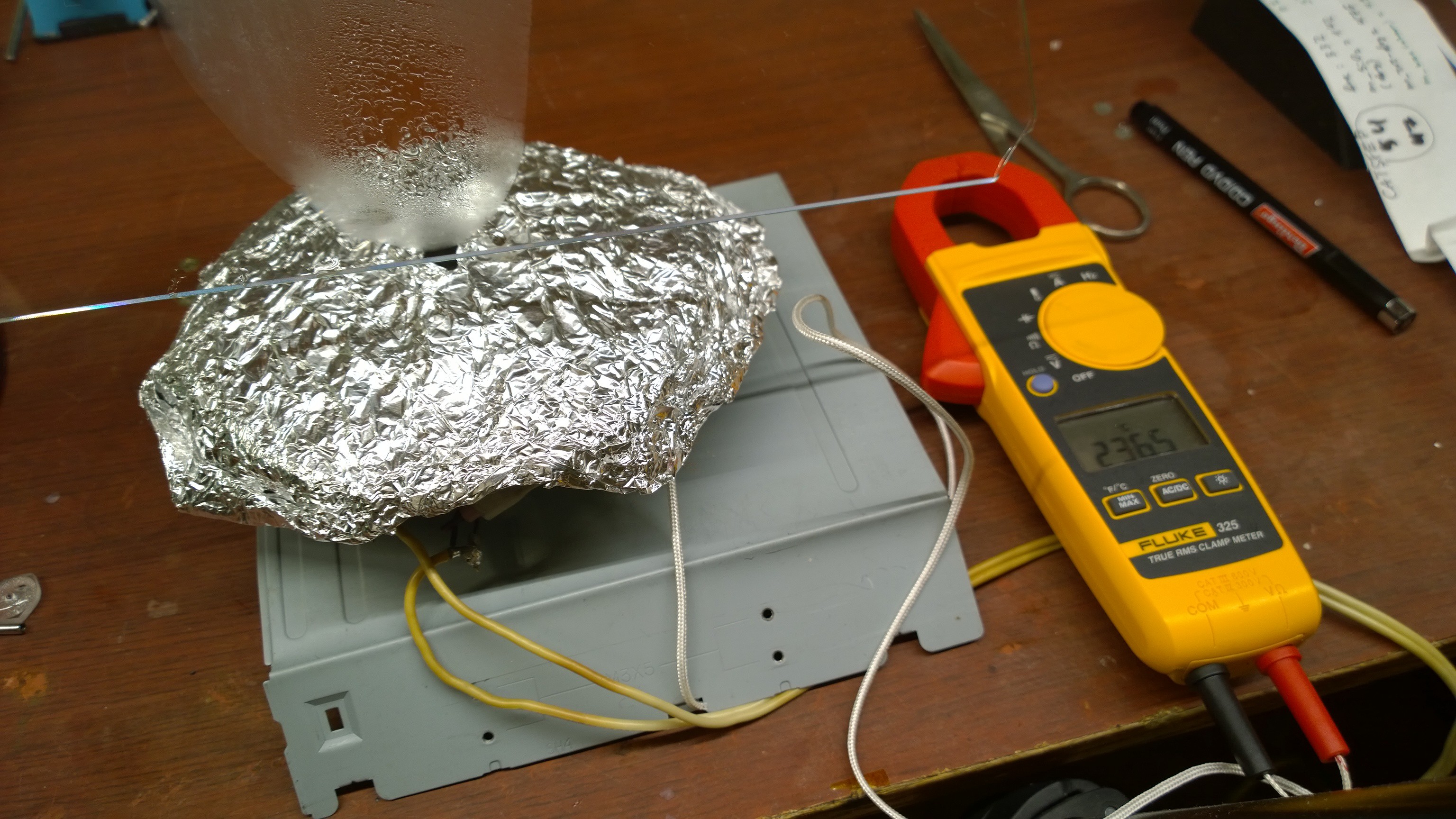

My crude silica gel dryer is made from a heater of an electric kettle, thermocouple to control the temperature and a phase regulator to adjust power. On top, I've put a few layers of aluminium foil, which is to provide thermal insulation and infrared reflectivity to help heat the silica gel inside more evenly. A hole in the top is to let the steam out.

It is ridiculously unsafe, with no overheating protection and exposed mains wiring. But, it allows me to easily test if the gel has finished drying or not, by placing something cold over the hole. If I see condensation - the gel isn't dry yet.

So I bought some boxes. Found some desiccant I've collected from various packages with stuff (I've been collected silica gel for just in case). Dried silica gel by heating it to 350°C (was too much, some beads turned brown). Put it into paper bad, and dropped it into the box with filament. I the box, I drilled a 2mm hole to pull the filament through. Sealed it up a bit with tape.

Next, after a day or two I did some printing. It was all right, but not as great as I anticipated.

About a week later, I decided to re-dry the silica gel to see, how much moisture it had adsorbed. To find out that it was probably saturated. At least, it was creating about as much steam as it did the first time I was drying it.

So, it became obvious I need to investigate the problem a little bit more, because re-drying the desiccant every week is not an option!

Also, I needed more silica gel, because the amount I had felt like only enough for one box with one spool. So I bough some silica gel cat litter, which is reasonably cheap, easy to obtain, and coarse-pored (allows to heat to higher temperature, so I can dry it faster).

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates