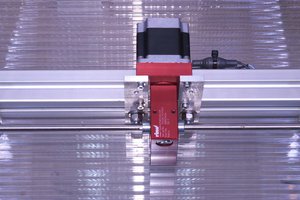

- The drive system has a DC motor with a diameter of 6 mm and an 0.5 modules 8 tooth pinion gear attached.

- A 42 mm super gear is attached so that it is sandwiched by 2 3 mm nuts on a 2 mm screw rod.

- Two 3 mm nuts are attached to the slide link printed with the 3D printer, and when the shaft rotates it will slide on the shaft.

- The screw pitch of the 2 mm shaft is 0.4 mm, and when the shaft rotates 32 times, the link travels about 12 mm.

- Link mechanism has a 2 x 2 mm magnet attached.

- On the other side of the super gear of the shaft, a 3D printed disk is mounted in the same way with a 3 mm nut, but two 2 mm x 2 mm magnets are mounted on that disk.

- The control CPU is ATTINY84, with three magnetic sensors, an H bridge type motor driver and a Piezo speaker.

- The two magnetic sensors detect the both ends of the travel.

- The servo interface sends a 10-bit data via serial Interface. From the host, you can specify the position, the power of the motor, the frequency of piezo speaker sound.

Masahiro Mizuno

Masahiro Mizuno

Elite Worm

Elite Worm

Mark Rehorst

Mark Rehorst

MasterOfNull

MasterOfNull