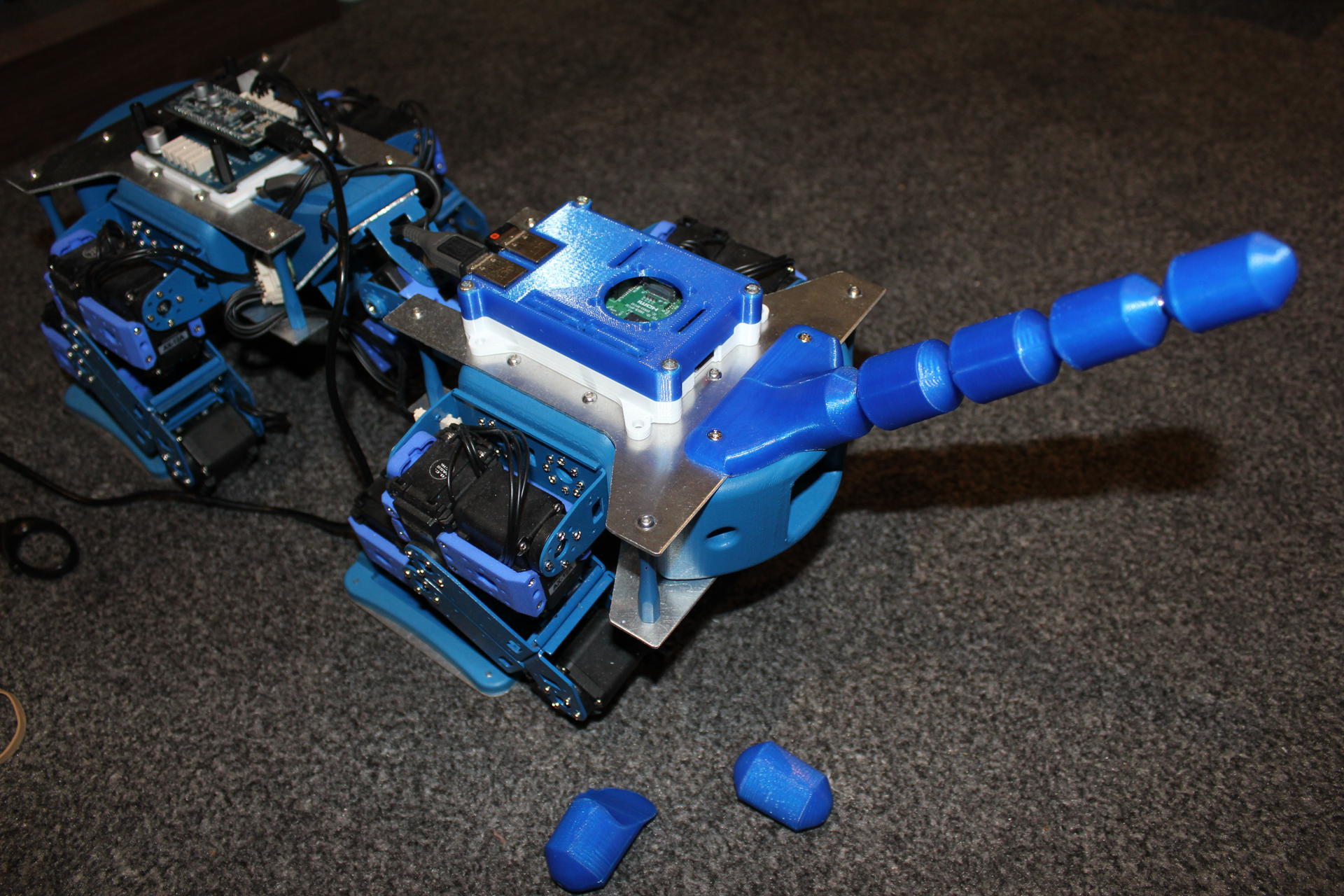

The tail has been built!

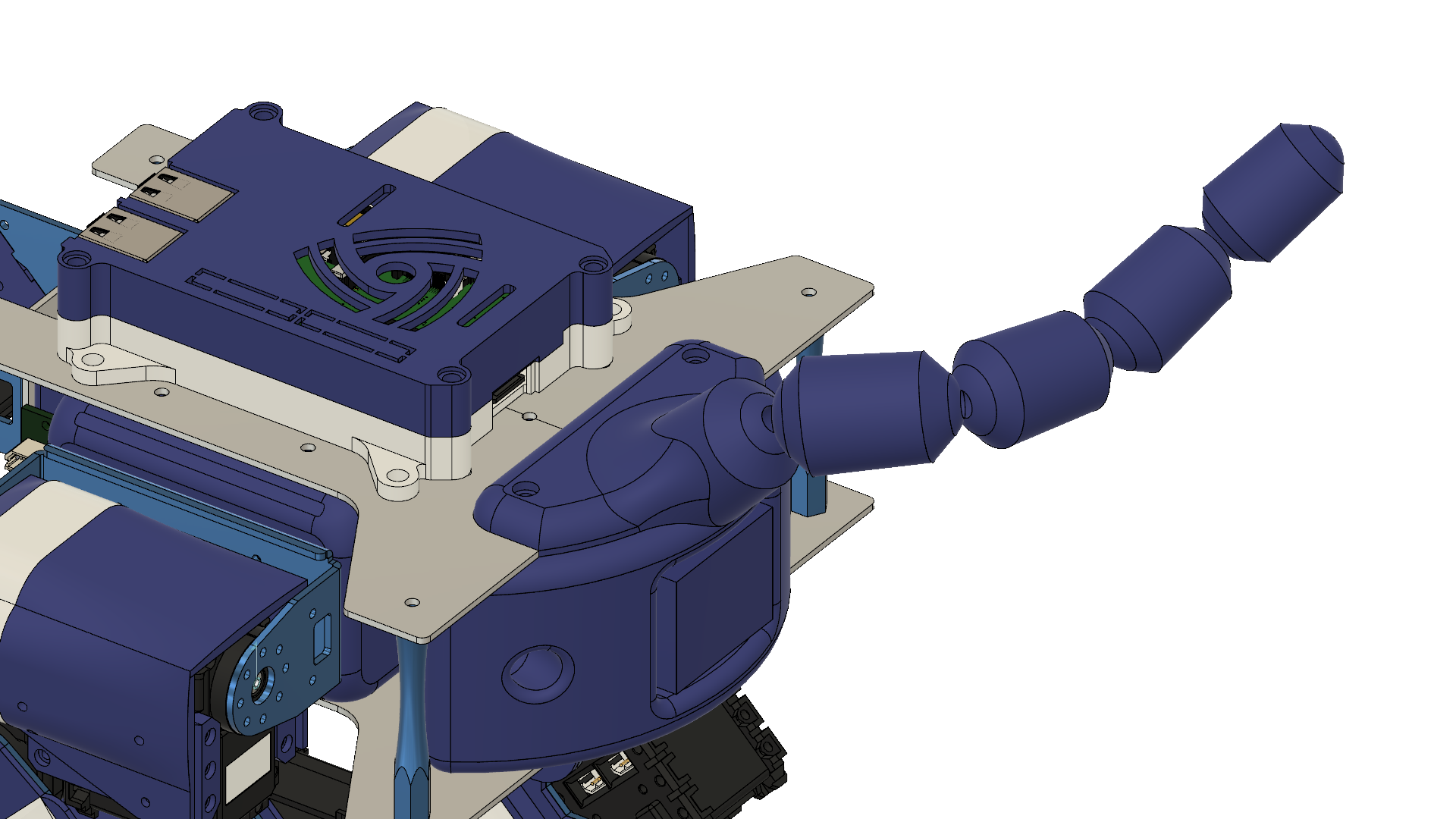

The CAD model went through a couple of iterations before deciding on the final form: from 8 polygonal sections to six smoother and smaller sections.

The CAD model went through a couple of iterations before deciding on the final form: from 8 polygonal sections to six smoother and smaller sections.

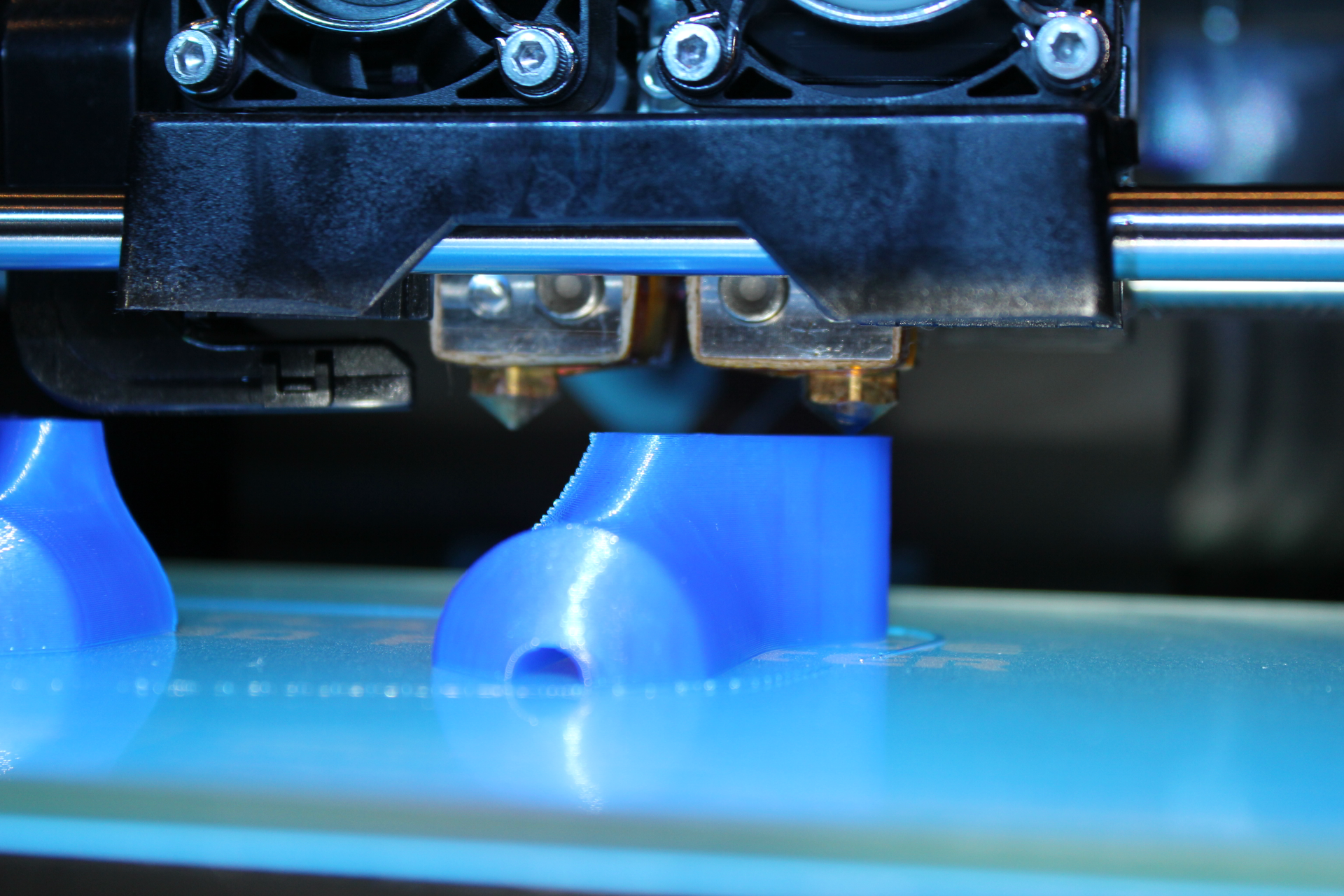

When 3D printing, the base section went through a re-design, since the original idea of just gluing the small section to the base was clearly not going to provide enough stability. I also removed yet another link, to avoid having the tail ending up too big and heavy.

The base section of the tail now screws onto two of the existing holes on the rear base, meaning there is no need to modify it, other than replacing two M3 bolts with longer ones.

The tail links are all held together with a 150 mm long, 5 mm diameter spring, scavenged from a flexible long reach pick-up tool.

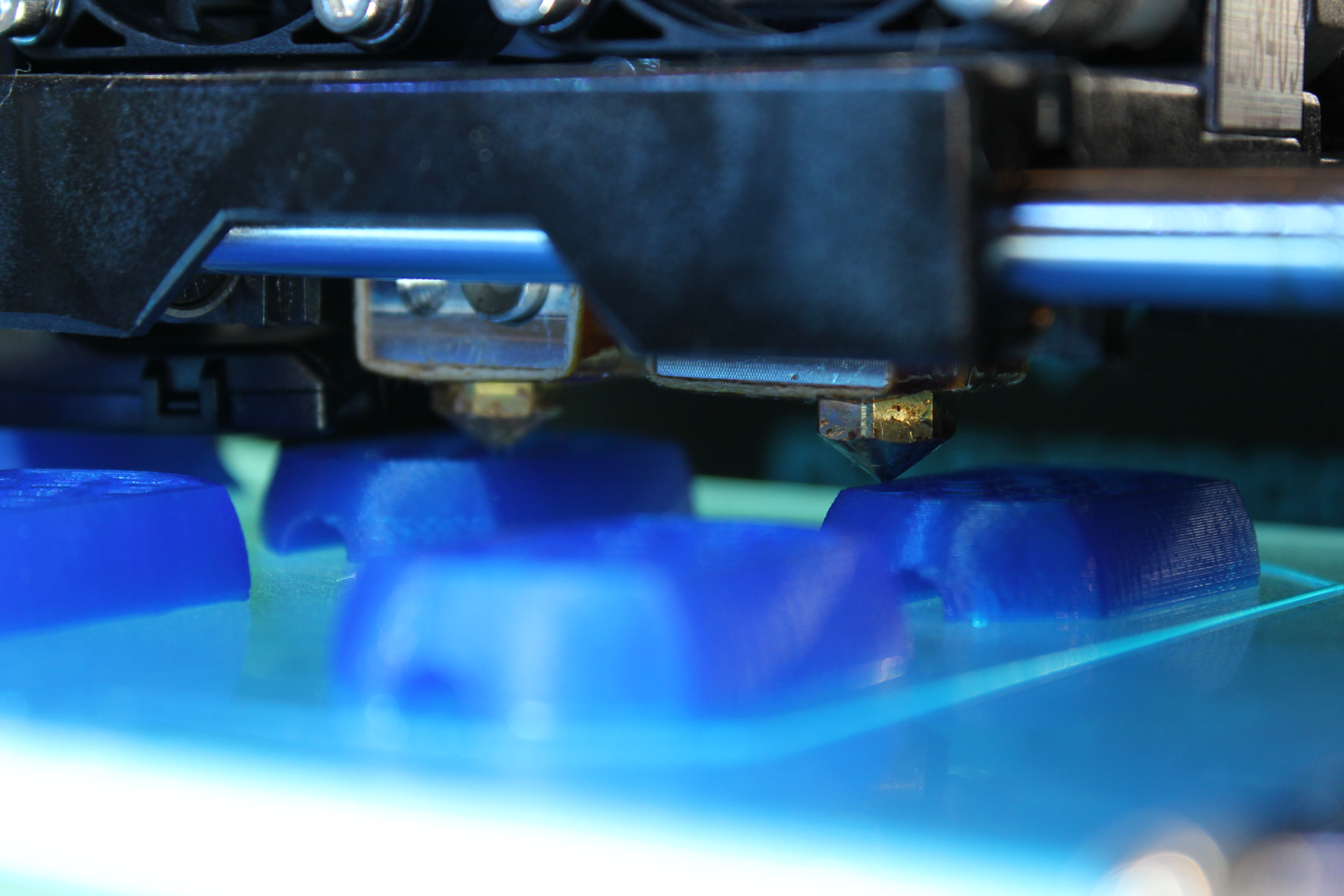

To make the models easy to 3D print, I sliced them all down the centre, then glued the halves together Loctite super glue works well with PLA (the gel type works best). There were a few failed prints in the process, which I put down to rushing, and using PLA which has been out in the air gathering moisture for several months! Prints were made on a Flashforge Creator Pro, with 15% infill.

Here are some pictures of the printing and assembly progress, leading to the final result:

Dimitris Xydas

Dimitris Xydas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.