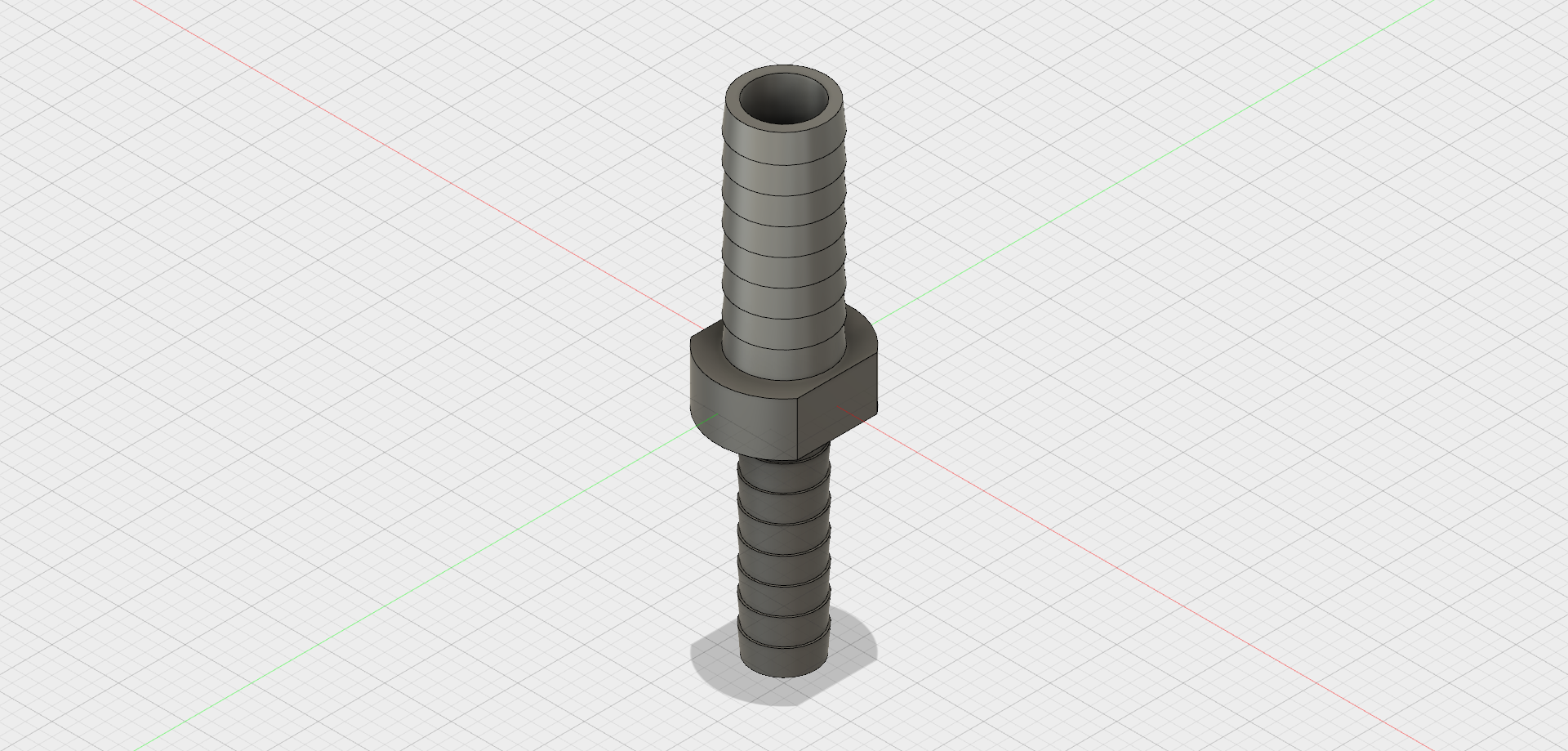

I grabbed my calipers, the fittings for the 1/2" tubing I got, and a scrap of the smaller pipe, and off to Fusion 360 I went. I designed a little barbed adapter between the two tube sizes and printed up a sample:

I went through a few iterations of the design, slightly changing the measurements to sneak up on a tight fit. Fusion 360 made that easy -- all I had to do was select the small end of the fitting and scale it up or down by 5% or so in the X and Y planes. I printed in PLA -- I'd have preferred ABS, but I don't have any. 100% infill.

The parts took about 1.5 hours to print each -- I needed two. Not too shabby after cleaning up the supports and raft:

I could have done better on the barbs for the smaller end. They should have been deeper, like on the large side, to bite into the tubing better. Oh well.

I was pleasantly surprised by how sturdy the fittings were. I was able to hammer them into the tubing with a soft hammer without any deformation. They are a little less resistant to bending forces -- I snapped a prototype off in a pipe by accident. That makes me think they fitting will be susceptible to breakage once buried, if someone steps right on one. But what are you going to do?

Here's the final fit up before burying it all:

I know PLA will probably degrade, but it's good enough for now, and I can always print more when they break. There was a small leak on the small sides, thanks to the not-sharp-enough barbs, but really, the whole point of sprinklers is to make the ground wet. If it gets a little wetter in one spot, what do I care?

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.