-

Two steps forward, one step back...

05/01/2021 at 16:08 • 1 commentI have been working on this project again with hopes to finish it soon enough so that I can proudly display it at home in some kind of enclosure.

The problem is that I always get new ideas for functionalities that require re-writing some code, adding new feature, or starting over again in a different programming language.

What started initially like a good way to display only the date and time, for which an Arduino is perfectly good enough became much more complex :I later thought it would fun to have games on it playable through a web browser, so I went on and redid everything for an ESP32 running a local webserver and displaying the weather, date, time, pixel drawing game and such. Worked perfectly fine but....

Finally I thought the best would be to have old games (pong, bricks, snake, flappy-bird like games...) playable on the display with a remote console gamepad... This added a whole new level of complexity having to pair bluetooth devices with the ESP32 (failed to do it), and ultimately switching to a Raspberry Pi, dropping the Arduino Framework for Pyhton and C code.

I now have the following result :Getting closer to a final product, but Raspberry Pis are much worse than Arduino and ESP32 at dealing with fast GPIO switching and I lost quite a bit of frame rate in the process. In the video, with only one pixel updating it's perfect, but with more dots to flip I get 1 to 2 fps, much too low for enjoying some games.

I should next try to combine the best of both worlds, The Raspberry Pi running the games and web stuff, and an Arduino or other uController dedicated to refreshing the display...

Stay tuned.

-

Daisy chained !

09/08/2018 at 22:39 • 0 commentsFinally managed to daisy chain my two displays for a total area of 60x16 dots, and as a bonus I wrote a library to make the display compatible with the Adafruit GFX library ! When I figure how GitHub works I'll post my code there as well.

Hope you enjoyed the teaser !

-

Prototyping finished.

09/06/2018 at 20:50 • 0 commentsThis concludes the hardware prototyping part. I'm genuinely surprised that the entire circuit works without any further modification, and that it could actually have been my final PCB.

All of the target functionalities were implemented and have been proven to work in previous logs :

- Have a controller that fits on the mounting holes of the ANNAX display

- Interface with the display using built-in dual IDC 40-pin connectors without modifications

- Flip and unflip dots at a pretty fast rate

- Illuminate the LED of the flipped dots

- Chain several displays and controllers together to expand fun area.

Minor modifications on the PCB would be to change the screw-terminal for the +24V input/output into a wire-to-board connector (maybe Molex ?), as it's currently quite a pain to connect/disconnect the cable when needed. And that's it ! The rest works.

A lot remains to be done though :

- Software : I need to write some kind of library for basic display functions (dot, line, rectangle, circle, text, icons, etc.) which would make my life easier when coding the final usage I want to do with the display, and make the webpage to control the display from any phone/tablet, making the whole thing IoT.

- Hardware : And in parallel, I need to revert to using the ESP32, and design a board for the ESP, some buttons and encoder, the level shifting required, and voltage/current regulation to complete the project

So it's far from being finished, but great steady progress were made over the past two months and I hope to keep it going this way.

-

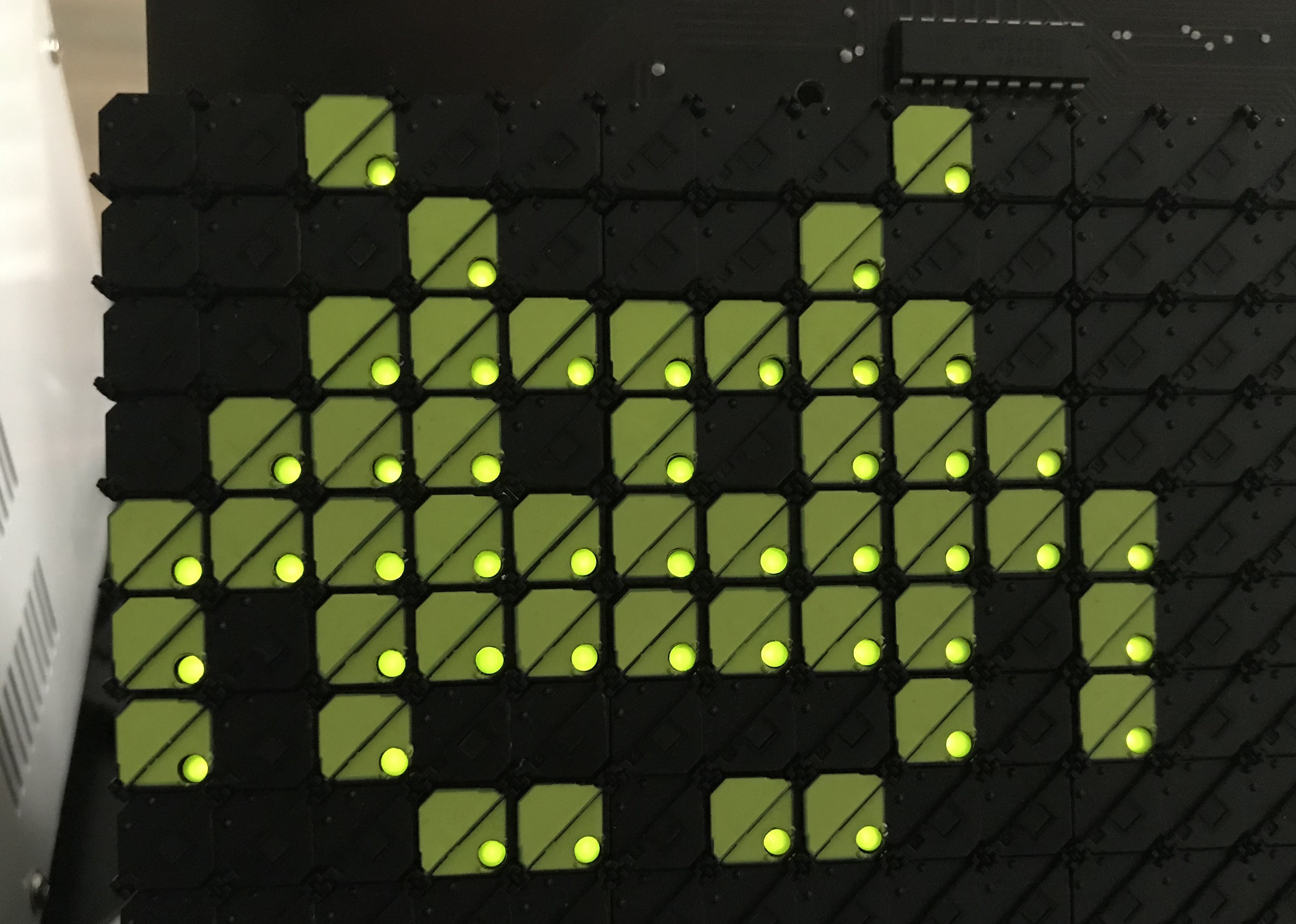

It glows B-)

09/01/2018 at 15:45 • 0 commentsFinally, I made some steps forward following the little setback of previous log. After the smoke, comes the glow :)

After a couple of weeks unsuccessfully trying to chain the displays together, I thought I'd try something different : attempt to drive the LEDs of the dots. It took me the whole day, but it does work pretty nicely !

As described previously when taking a close look at the ANNAX display, all 16 rows of LED anodes are connected to two 8ch source driver controlled by two 8 bits shift registers. Those 4 chips are integrated onto the display.

The LED cathodes are linked per columns and connected to the flipdots column sink drivers (on my controller).

So in order to drive the LED we need to go through each columns one by one, load the 16 bits representing each 16 dots state for that column, illuminate the LEDs, move onto the next column, and repeat. If done fast enough, we don't see the blinking and the illumination feels quite natural. The flickering on the video is from the camera and isn't visible to the naked eye.

Now the code is a bit more complex as I used my updated code and functions that I'm continuously tweaking and improving for broader usage.

Basically there are two important variables : current_display[] and new_display[].

Both are array of bits (30x16) representing the current and requested state of the display.

Any modification to the display is done on the new_display[] array, then the code compares the current state and requested state of the display, and only the necessary dots are being flipped and unflipped.

The rest is commented, but feel free to ask if you have questions.

#include <Arduino.h> #include <SPI.h> // SPI pins for sending data into shift registers #define SPI_SPEED 1000000 // 1 Mhz #define PIN_CS_ROW 10 //22 #define PIN_CS_COL 9 //21 #define PIN_RST_ROW 8 //2 #define PIN_RST_COL 7 //0 // Pins used for flipping dots #define PIN_SET_RESET 6 //4 #define PIN_PULSE 5 //15 // Pins for LED control #define PIN_LED_OE 3 // PWM PIN #define PIN_LED_STR 2 // Fixed parameters #define PULSE_LENGTH_US 200 // May be adjusted according to voltage used #define SET 1 // HIGH #define RESET 0 // LOW // Display params #define DISPLAY_WIDTH 30 // Only 1 display connected for now #define DISPLAY_HEIGHT 16 uint16_t current_display[DISPLAY_WIDTH]; uint16_t new_display[DISPLAY_WIDTH]; // 8bit Space Invader const unsigned char monster8x11[] = { 0b01110000, 0b00011000, 0b01111101, 0b10111110, 0b10110100, 0b00111100, 0b10110100, 0b10111110, 0b01111101, 0b00011000, 0b01110000 }; void clear_registers(){ // Clear Shift Registers // I have doubt if this is working as datasheet is confusing digitalWrite(PIN_RST_ROW, LOW); digitalWrite(PIN_RST_COL, LOW); delayMicroseconds(1); digitalWrite(PIN_RST_ROW, HIGH); digitalWrite(PIN_RST_COL, HIGH); } void load_single_dot(uint8_t x, uint8_t y){ // This method safely pre-loads all SR with zeros and only 1 bit set at the // requested x and y position. // Currently this method is implemented for // 2 horizontally daisy chained 30x16 displays (2x1) // ______________________________ ______________________________ // | |->| | // | DISPLAY 1 |->| DISPLAY 2 | // | (30 x 16) |->| (30 x 16) | // | |->| | // |______________________________|->|______________________________| // // Any other arrangements "3x1" displays or "2x2" or "1x2" are possible, // but modifications have to be made in the order of bytes of data // sent to the registers and number of bytes sent to accomodate for each // individual setup and how shift registers are connected // (vertically vs horizontally). 25 dots width displays can be used as well. // Clear shift register data, but if it doesn't work it's not a problem // as we send bytes to all SR of the two controllers. clear_registers(); // Insert 2 dummy bits for unused output 31 and 32 of shift registers // in the case of a 30 dots wide display with a controller of 4 SR (32 bits) // May have to be adjusted if using a 25 dots wide display with 4 SR. if(x >= 30) { x+=2; } // Initialise SPI communication SPI.beginTransaction(SPISettings(SPI_SPEED, MSBFIRST, SPI_MODE0)); // COORDINATE X : digitalWrite (PIN_CS_COL, LOW); // Slave Select Columns shift registers for(int b=7; b>=0; b--){ // Transfer as many bytes as number of column SR on all controllers (8) if((int) (x/8) == b){ // Transfer a 1 into the correct position of correct SR SPI.transfer(0x01 << (x%8)); } else { // Transfer 0s to other SR to blank any remaining other data SPI.transfer(0x00); } } // End Slave Select Columns digitalWrite (PIN_CS_COL, HIGH); // COORDINATE Y : digitalWrite (PIN_CS_ROW, LOW); // Slave Select Rows shift registers if(x>=32) { // Targeting display 2, so we increase y by 16 to address its SR y += 16; } for(int b=3; b>=0; b--){ // Transfer as many bytes as number of row SR on all controllers (4) if((int) (y/8) == b){ // Transfer a 1 into the correct position of correct SR SPI.transfer(0x01 << (y%8)); } else { // Transfer 0s to other SR to blank any remaining other data SPI.transfer(0x00); } } digitalWrite (PIN_CS_ROW, HIGH); // End Slave Select Rows SPI.endTransaction(); // End SPI } void flip(bool dir, int delay_ms=1) { digitalWrite(PIN_SET_RESET, dir); delayMicroseconds(1); // Send pulse digitalWrite(PIN_PULSE, HIGH); delayMicroseconds(PULSE_LENGTH_US); digitalWrite(PIN_PULSE, LOW); // Revert to SET/RESET HIGH to allow for LED on digitalWrite(PIN_SET_RESET, HIGH); } void update_display() { // Compare new_display[] and current_display[] // Dots are flipped or unflipped only where necessary. // Once display updated, current_display = new_display, ready for next update. clear_registers(); uint16_t to_change = 0x0000; // For each columns for(int col = 0; col<DISPLAY_WIDTH; col++){ // Isolate dots to RESET to_change = current_display[col] & ~new_display[col]; for(int row = 0; row<16; row++) { if(bitRead(to_change, row)) { load_single_dot(col, row); flip(RESET); } } // Isolate dots to SET to_change = ~current_display[col] & new_display[col]; for(int row = 0; row<16; row++) { if(bitRead(to_change, row)) { load_single_dot(col, row); flip(SET); } } } //current_display[] = new_display[]; memcpy(current_display, new_display, sizeof(current_display)); } void draw_monster_icon(int x, int y) { for(int i=0; i<11; i++){ new_display[i+x] |= monster8x11[i] << y; } } void clear_display(){ for(int i=0; i<DISPLAY_WIDTH; i++){ new_display[i] = 0x0000; } } // Animate monster int pos_x = 0; int pos_y = 0; int h = 1; int v = 1; int max_x = 19; int max_y = 8; unsigned long last_frame = 0; void animate_monster(int rate_ms = 1000) { if(millis()-last_frame > rate_ms){ // Time to update animation clear_display(); draw_monster_icon(pos_x,pos_y); update_display(); last_frame = millis(); // next coordinates : pos_x += h; pos_y += v; if(pos_x >= max_x){ h = -1; } if(pos_x <= 0){ h = 1; } if(pos_y >= max_y){ v = -1; } if(pos_y <= 0){ v = 1; } } } // LED led driving void led_driving() { // For each column, illuminate flipped dot LED for(int col = 0; col<DISPLAY_WIDTH; col++) { load_single_dot(col, 0); // load column in COL SR, and any row. SPI.beginTransaction(SPISettings(SPI_SPEED, LSBFIRST, SPI_MODE0)); // ROW digitalWrite (PIN_LED_STR, HIGH); // Slave Select LED Rows SPI.transfer(current_display[col] >> 8); // Lower part of screen SPI.transfer(current_display[col]); // Top part of screen digitalWrite (PIN_LED_STR, LOW); // End Slave Select LED Rows SPI.endTransaction(); // End SPI analogWrite(PIN_LED_OE, 255); // LED BRIGHTNESS 0 = OFF; 255 = MAX } } void setup() { // Defining outputs pinMode(PIN_CS_ROW, OUTPUT); pinMode(PIN_CS_COL, OUTPUT); pinMode(PIN_RST_ROW, OUTPUT); pinMode(PIN_RST_COL, OUTPUT); pinMode(PIN_SET_RESET, OUTPUT); pinMode(PIN_PULSE, OUTPUT); pinMode(PIN_LED_OE, OUTPUT); pinMode(PIN_LED_STR, OUTPUT); // Initial outputs state digitalWrite(PIN_CS_ROW, HIGH); digitalWrite(PIN_CS_COL, HIGH); digitalWrite(PIN_SET_RESET, LOW); digitalWrite(PIN_PULSE, LOW); digitalWrite(PIN_LED_OE, LOW); digitalWrite(PIN_LED_STR, LOW); // Clear Shift Registers clear_registers(); SPI.begin(); delay(5000); } void loop() { animate_monster(1000); led_driving(); }Strangely, I didn't have to provide extra power to the LED as the integrated voltage regulator seems to be able to provide enough current to make the nice glow shown above. The brightness can be increased if needed by plugging +5V on the display TAB connector, and then adjusting the PWM output value in the code.

The only thing left now is to figure out how to chain displays (seems easy on paper, but can't make it work so far), and once this works I will move onto designing the final control board.

-

Smoke test failed :(

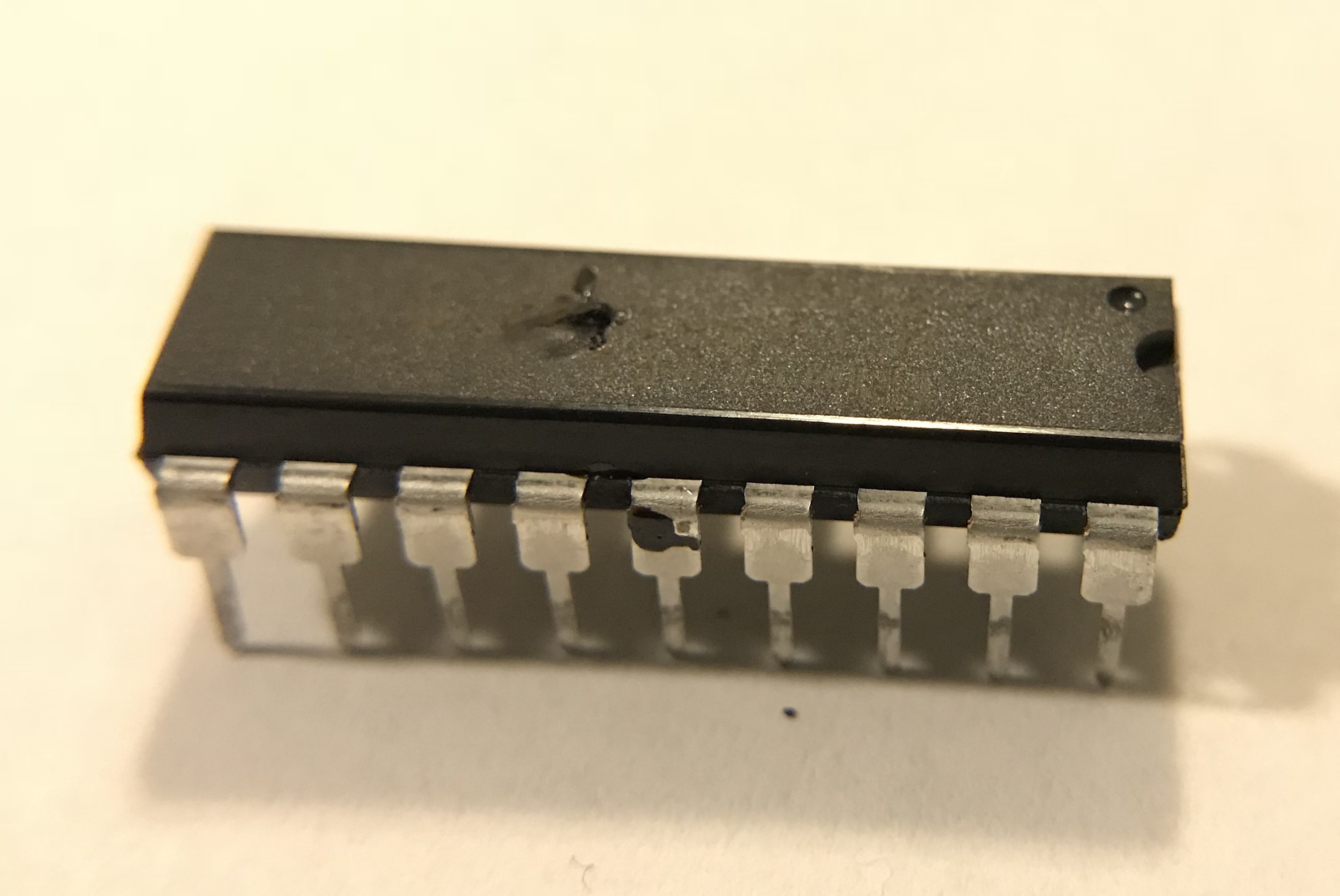

08/20/2018 at 22:13 • 4 commentsYep, you heard me. Plugged in the supply, 5 seconds later heard a sizzling sound and a nice blue smoke came out from behind the display. Just before that, a couple of random columns went from black to yellow (the whole column, at once).

I haven’t had the pleasure to experience this acrid smell in quite a long time, so it brought back some memories. Unplugged the supply straight away and got ready to throw all out in case it caught fire, but it decided it was enough of a warning, and settled down slowly.

After I thought it was safe enough, I approached the beast to assess whatever damages I did to the poor thing. Luckily it seems it remained contained. One MIC2981 source driver is certainly out of service and was definitely the source of the smoke.

There might be some other damages but they are well hidden, as all other chips and PCB look fine to the naked eye. Nevertheless I was happy to have planned ahead and put the drivers on DIP sockets to facilitate replacement (as if I knew I would burn a few...).

What happened ? I’m not really sure, and it’s very annoying, as now I have this feeling it’ll burn again every time I plug in the supply. So far I think either one of the ground cable got disconnected and the ESP32 had a different ground reference than the control board, making its behaviour erratic, or the ESP32 had some power problem as it wouldn’t run the code properly when checking the outputs with the oscilloscope at a later stage.

The code itself wasn’t faulty as I wasn’t trying anything crazy or demanding as I have been in the previous log when blinking the whole display at max rate. The ESP32 wasn’t running the code for some reason, maybe was booting or re-boooting, during which the outputs went awol and may have loaded the shift registers with corrupted data, and at the same time sent a continuous pulse. This would explain the two columns flipping simultaneously, followed by the burning chip that couldn’t handle the current of that many simultaneous dots flipping (source and sink drivers are rated to 500mA per channel).

Legs up, as in... DEAD.

Having replaced the burnt chip, it seems I still have some troubleshooting to do as I cannot unflip dots. It’s a time consuming task and quite a setback as things were going so smoothly so far. I truly hope I haven’t damaged any of the coils or other parts of the display, but having been able to flip all remaining dots to yellow side seems reassuring.

I just finished soldering a second control board for my second display as I was about to try daisy chaining both displays, so I will probably use it to help isolate the remaining problems. Also, I may temporarily swap the ESP32 for an Arduino for more stability during the testing phase.

EDIT 26th August 2018 : The display is fine and doesn't have any damages. My control board has some burnt drivers, and 9 out of 12 shift registers have erratic behaviour. Those not being on DIP sockets, I'll have to re-solder a complete new board to go onto the next step of prototyping, ie. daisy-chaining, and making the LEDs work. It'll take a bit longer as I need to re-stock some components, but come back soon for updates ! -

IT FLIPS !!!

08/19/2018 at 07:10 • 2 commentsToday I earned the dot flipper badge, and a milestone in this project has been reached. Those few weeks of hard work, figuring all out, selecting components, designing a PCB and coding a simple firmware finally paid off !

Below is my very first dot flipped, and you cannot imagine how excited I was when I heard the clicking sound after plugging in the power supply. More tests shown below.

I kept the code as simple as possible :

- Define the outputs (setup)

- Load coordinates of the dot to flip into the rows and columns shift registers (load_single_dot function)

- Send the pulse (flip function)

- Toggle modes between SET and RESET

- Repeat every 2 seconds

#include <Arduino.h> #include <SPI.h> // Using SPI is faster than bit-banging in that case // SPI pins for sending data into shift registers #define SPI_SPEED 8000000 // 8 Mhz #define PIN_CS_ROW 22 #define PIN_CS_COL 21 #define PIN_RST_ROW 2 #define PIN_RST_COL 0 // Pins used for flipping dots #define PIN_SET_RESET 4 #define PIN_PULSE 15 // Fixed parameters #define PULSE_LENGTH_US 200 // May be adjusted according to voltage used #define SET 1 // HIGH #define RESET 0 // LOW void clear_registers() { // Resets shift registers digitalWrite(PIN_RST_ROW, LOW); digitalWrite(PIN_RST_COL, LOW); delayMicroseconds(1); digitalWrite(PIN_RST_ROW, HIGH); digitalWrite(PIN_RST_COL, HIGH); } void load_single_dot(uint8_t x, uint8_t y){ // Clear shift register data clear_registers(); // Initialise SPI communication SPI.beginTransaction(SPISettings(SPI_SPEED, MSBFIRST, SPI_MODE0)); // Transmit coordinate x and y coordinates to shift registers : // Slave Select Columns shift registers digitalWrite (PIN_CS_COL, LOW); SPI.transfer(1 << (x%8)); for(int i=0; i<(x/8); i++){ // Insert 8 blank bits 'spacers' if x>=8 SPI.transfer(0x00); } digitalWrite (PIN_CS_COL, HIGH); // Slave Select Rows shift registers digitalWrite (PIN_CS_ROW, LOW); // 16 rows, so let's send all 16 bits at once, it's overall faster. SPI.transfer16(1 << y); digitalWrite (PIN_CS_ROW, HIGH); // End SPI SPI.endTransaction(); } void flip(bool dir) { // SET or RESET mode digitalWrite(PIN_SET_RESET, dir); delayMicroseconds(1); // Send pulse digitalWrite(PIN_PULSE, HIGH); delayMicroseconds(PULSE_LENGTH_US); digitalWrite(PIN_PULSE, LOW); } void setup() { // Defining outputs pinMode(PIN_CS_ROW, OUTPUT); pinMode(PIN_CS_COL, OUTPUT); pinMode(PIN_RST_ROW, OUTPUT); pinMode(PIN_RST_COL, OUTPUT); pinMode(PIN_SET_RESET, OUTPUT); pinMode(PIN_PULSE, OUTPUT); // Initial outputs state digitalWrite(PIN_SET_RESET, LOW); digitalWrite(PIN_PULSE, LOW); // Clear Shift Registers clear_registers(); SPI.begin(); } void loop() { // Load (x,y) coordinates of dot to flip load_single_dot(0, 0); flip(SET); // YELLOW delay(2000); flip(RESET); // BLACK delay(2000); }

I eyeballed the pulse length to 200us for a start, thinking I would have to increase it to a higher value, but it seems to work perfectly and I might even be able to reduce it a touch. It would increase the overall frame rate, as waiting for the pulses to complete is the most time consuming task of the process (loading the shift registers takes on average 20us per dot).

Anyway, here is what I got flipping each dot every 200ms, and finally at full speed without any delay.

I’m quite impressed, knowing this is only the very first tests and a lot of optimisation is possible ! Stay tuned, while I hypnotise myself looking at it.

BONUS VIDEOS :

-

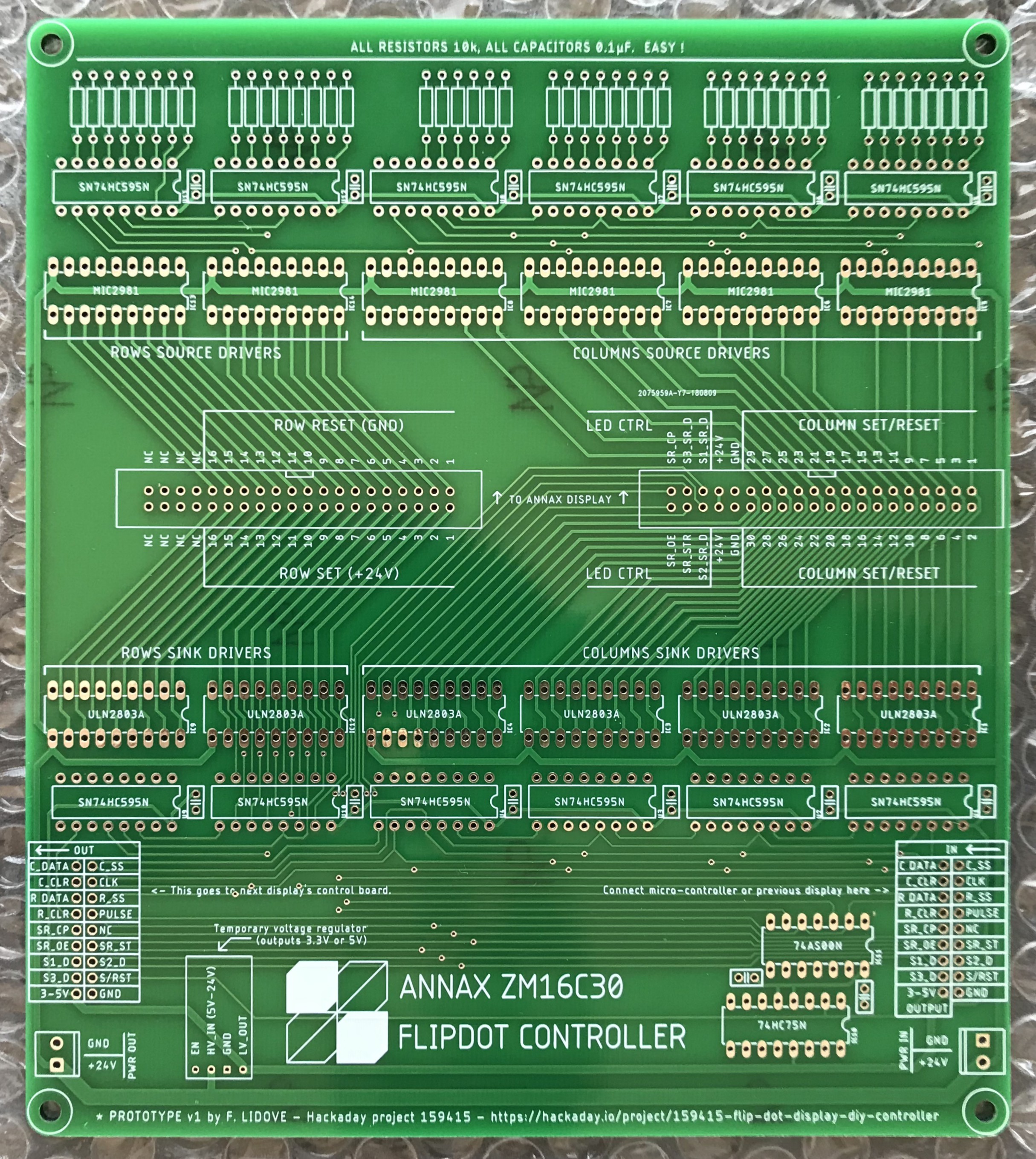

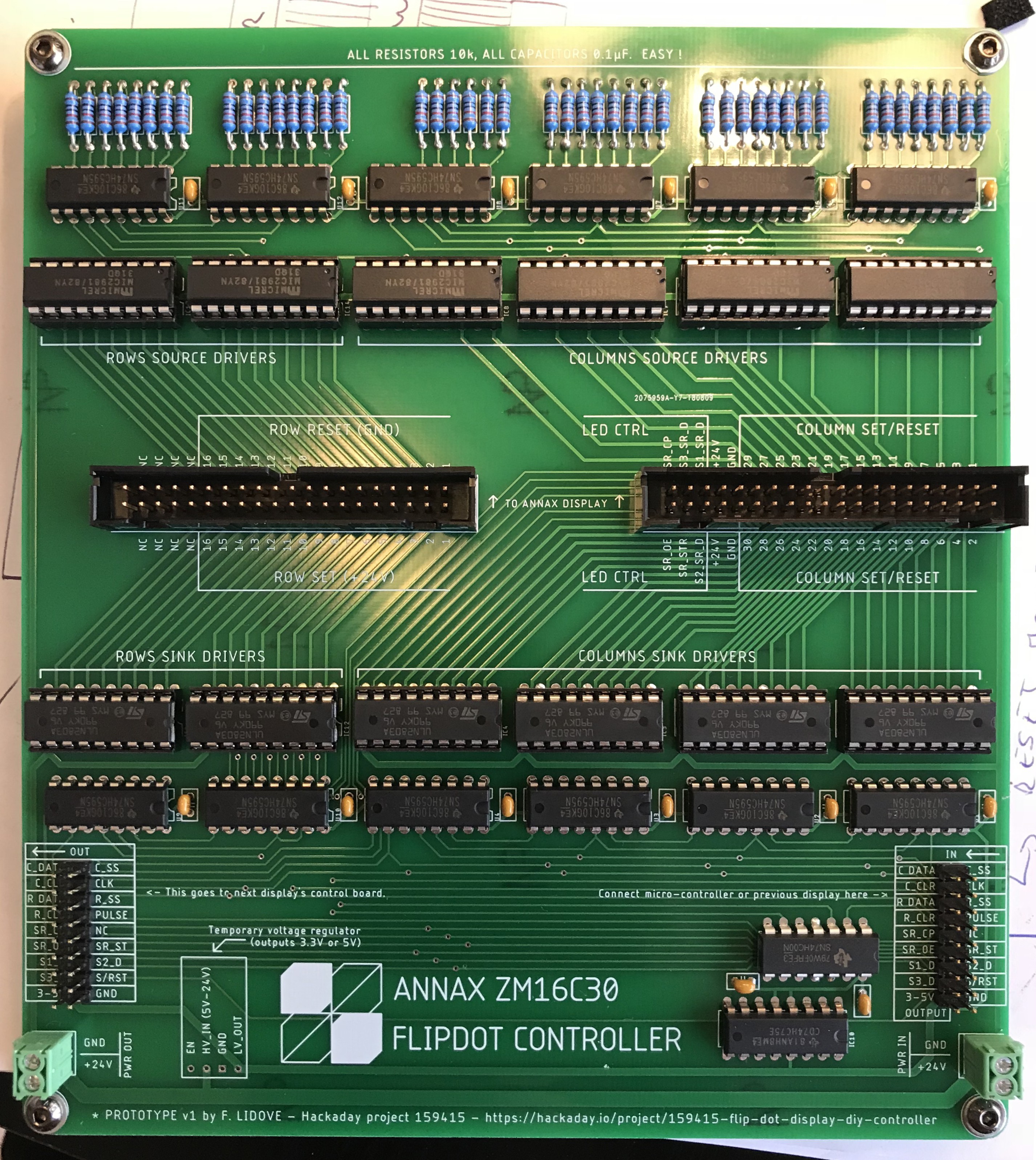

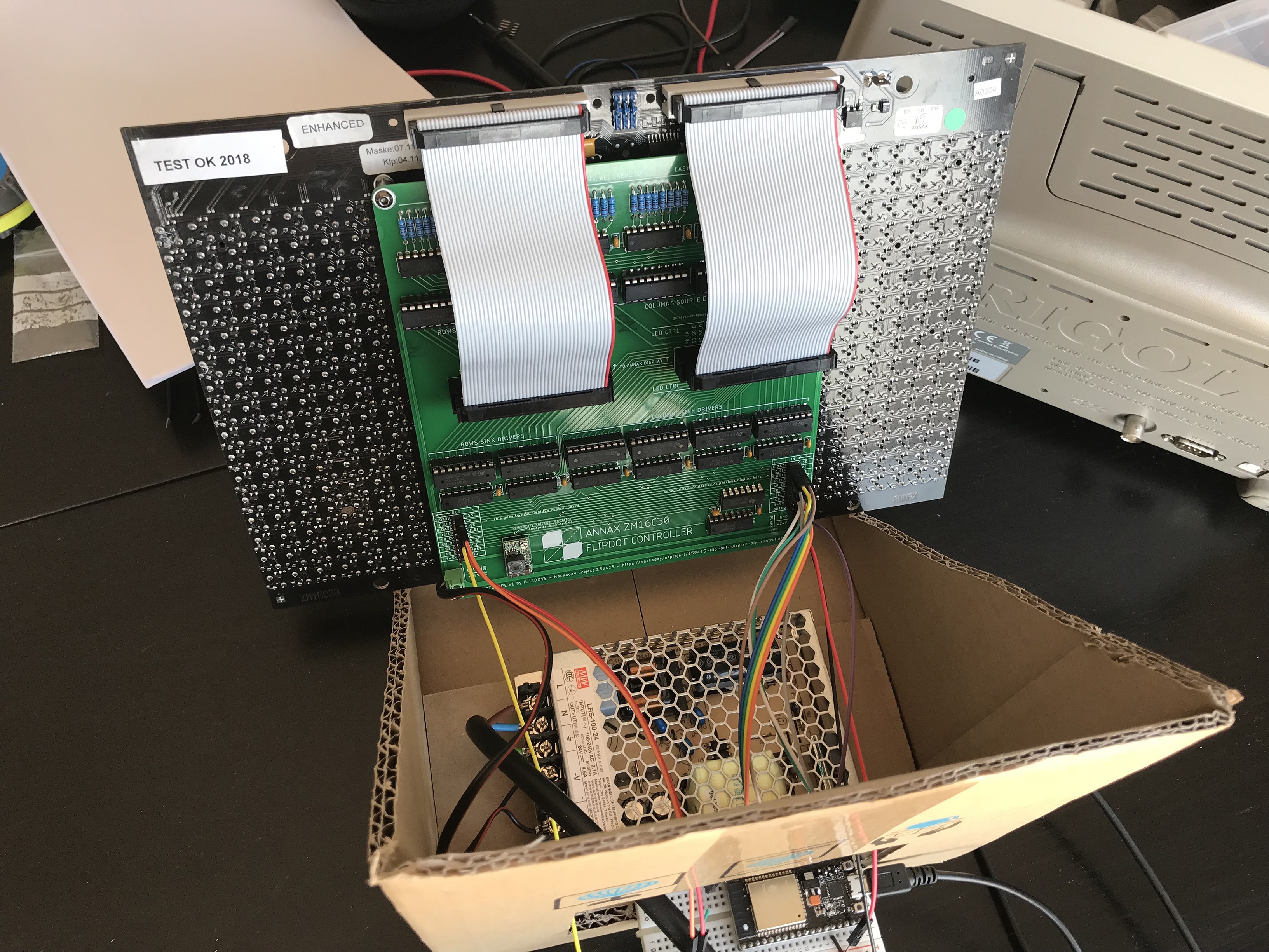

Controller assembled and ready for tests.

08/18/2018 at 10:20 • 0 commentsGot the parts yesterday and started putting it all together. Here is the board as I received it from JLCPCB, and the final result with all the components soldered (not my best soldering job but got much better at it towards the end).

![]()

![]()

![]()

The board fits nicely on the back of the display with 10mm spacers. The 40pins connectors are aligned with the ones from the display and all seems to fit as I was hoping. You can see the power supply here as well in the temporary cardboard support.

I could only find a couple of small mistakes so far :

- The pads holes for the voltage regulator module are too small, so instead of using standard PIN headers I had to solder stripped wires

- The silkscreen should read ROW SET (+24) above connector 1 and ROW RESET (GND) below it, instead of the opposite

I’ll make sure I’ll correct those before posting the board and schematic on GitHub.

Off to some coding and hopefully dots will flip soon !

-

Flipdot prototype BOM

08/11/2018 at 07:18 • 0 commentsWith the PCB on their way and expected to arrive next week, it was time to order the components required for the assembly. Here is a table with the references used, quantity and unit price (for ONE display).

Description Reference Quan-tity Unit Price Total Price Shift Register SN74HC595N 12 0,374 € 4,488 € Source Driver MIC2981/82YN 6 1,74 € 10,44 € Sink Driver ULN2803A 6 0,867 € 5,202 € 10k Resistors MFR-25FBF52-10K 48 0,017 € 0,816 € 0.1uF Capacitor K104K15X7RF53L2 14 0,039 € 0,546 € IC Sockets for Drivers 1-2199298-5 12 0,179 € 2,148 € 40 pos. flat cable (1 ft) 3365/40-CUT-LENGTH 1 1,39 € 1,39 € 40 pos. Board Connector 5103308-8 2 1,99 € 3,98 € 40 pos. Cable Header 1658621-9 4 1,30 € 5,2 € 40 pos. Header Strain Relief 499252-1 4 0,241 € 0,964 € 18 pos. Cable Header (for daisy chaining) 71600-318LF 2 1,41 € 2,82 € NAND Gate SN74HC00N 1 0,408 € 0,408 € Bistable Latch CD74HC75E 1 0,757 € 0,757 € 9x2 Pin Strip (for daisy chaining) 67997-218HLF 2 0,587 € 1,174 € 24V Power Supply LRS-100-24 1 15,91 € 15,91 € TOTAL 56,25€

A total of 40 € of components (excluding the power supply), for 1 display, so 80€ in my case as I want to try daisy chaining both displays together. A bit pricey for a prototype but some components will be re-usable, such as the drivers (mounted on sockets), and cable assemblies.

-

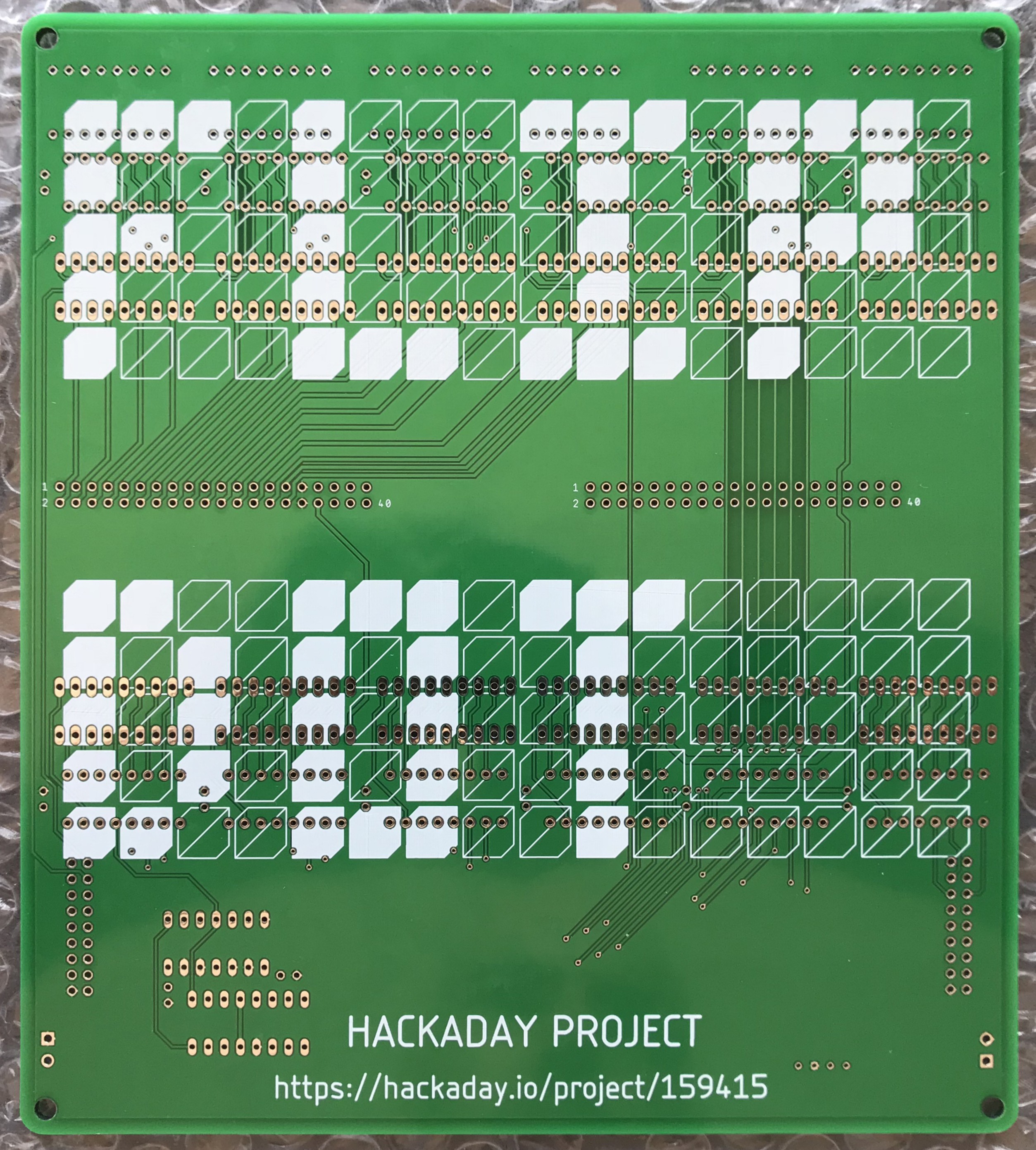

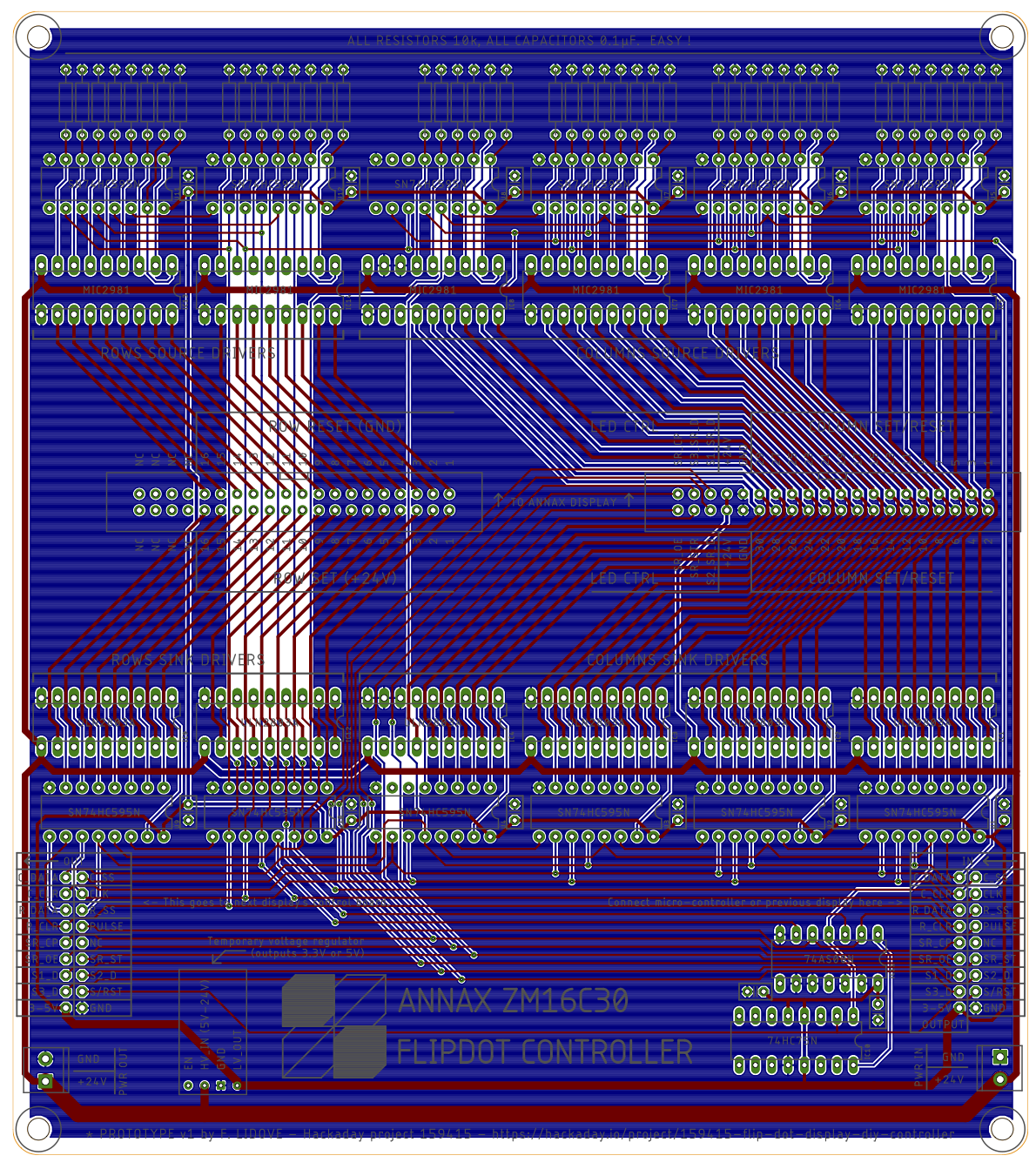

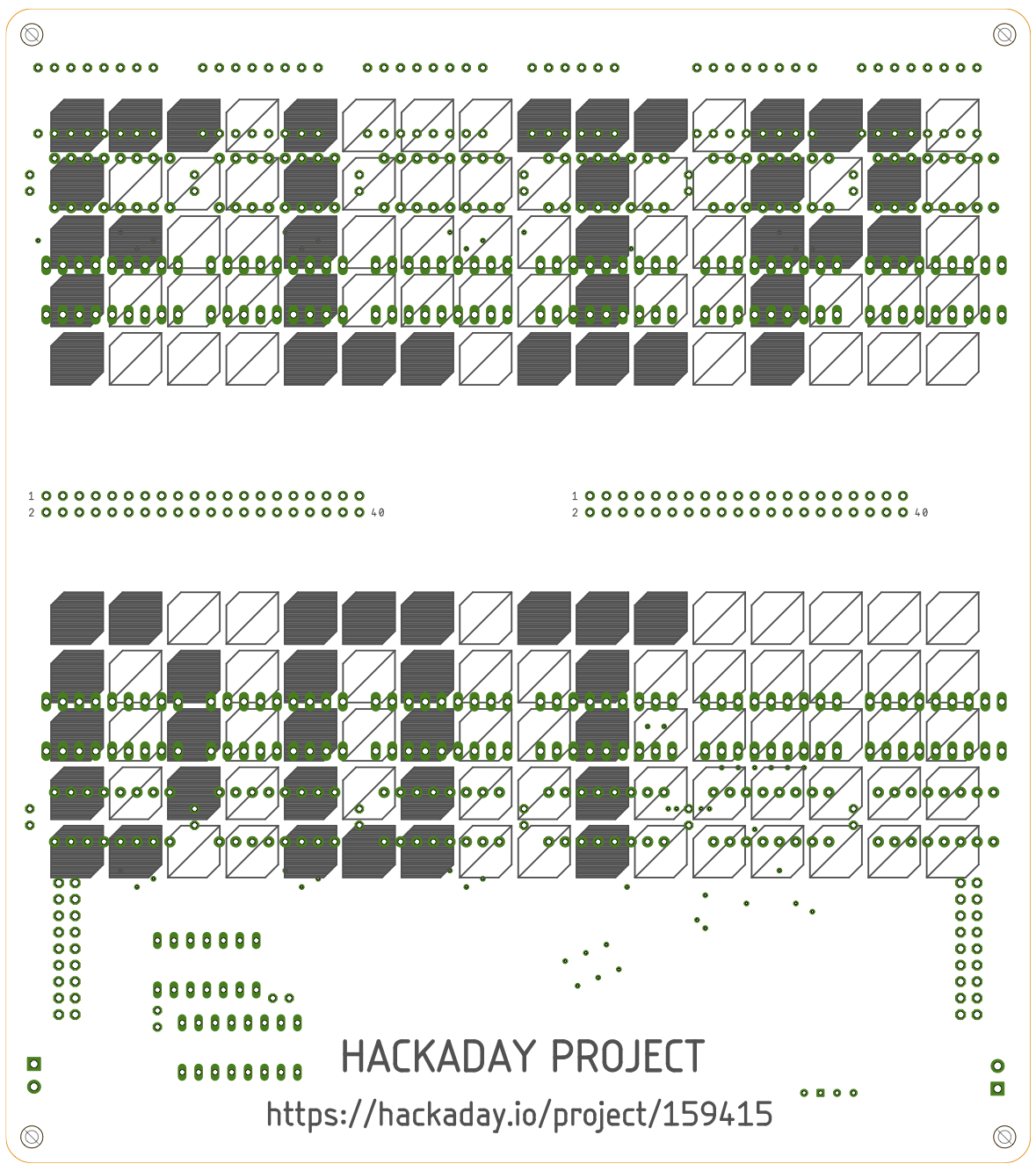

Prototype PCB design

08/08/2018 at 16:04 • 0 commentsIt turns out the schematic from previous log contains around 200 wires, that is, for one display. I have neither the patience to cut to length and strip 400 wires nor do I have enough breadboards to accommodate for all the ICs in order to run my two displays.

So, for the price of extra breadboards and wires, I can have a PCB manufactured, which not only will eliminate (or at least reduce) the risks of mis-wiring, but also will keep the “lab” (read: my living room) tidy. The only downside is that I loose the flexibility of changing the circuit on the go, but I worked hard on the schematic (even harder on the PCB layout) and I believe it should work.

The PCB size is based on the available ANNAX mounting holes and should fit nicely on its back with a few spacers. I chose only through holes components for ease of soldering as well as for ease of changing burnt ICs (plan for the worse, hope for the best). The ones most susceptible to get grilled are the source and sink drivers, so I’ll mount those on sockets.

Having through-hole components all over the board, and trying to keep them all on the same side (reducing overall thickness) was a real challenge as it restricts the available space for routing, but I managed to make it work, hopefully without breaking too many laws of good PCB design (eg. the GND plane on the back has more signal lines cutting through it than I would have liked).

The PCBs have been ordered from JLCPCB. I have used a few time past and I was pleased with the results. Five boards for 16€, one week delivery for 24€, for a total cost of 40€ (standard delivery was 12€ only but I'm in a rush to get started).

Here are some screenshots of the layout, I took the liberty to make some silkscreen “art” on the back but the result might not be as expected as there are vias and through-hole pads literally everywhere.

![]()

Layout output from Eagle ![]()

Improvised "PCB art" on the back On the final board, at a later stage, I’ll probably use SMD components to have more space to integrate an appropriate voltage regulator, some level shifting chips, and the ESP32. Maybe a nice soldermask color, and higher quality surface finish, would make for a cleaner, all in one final product, ready to be framed !

-

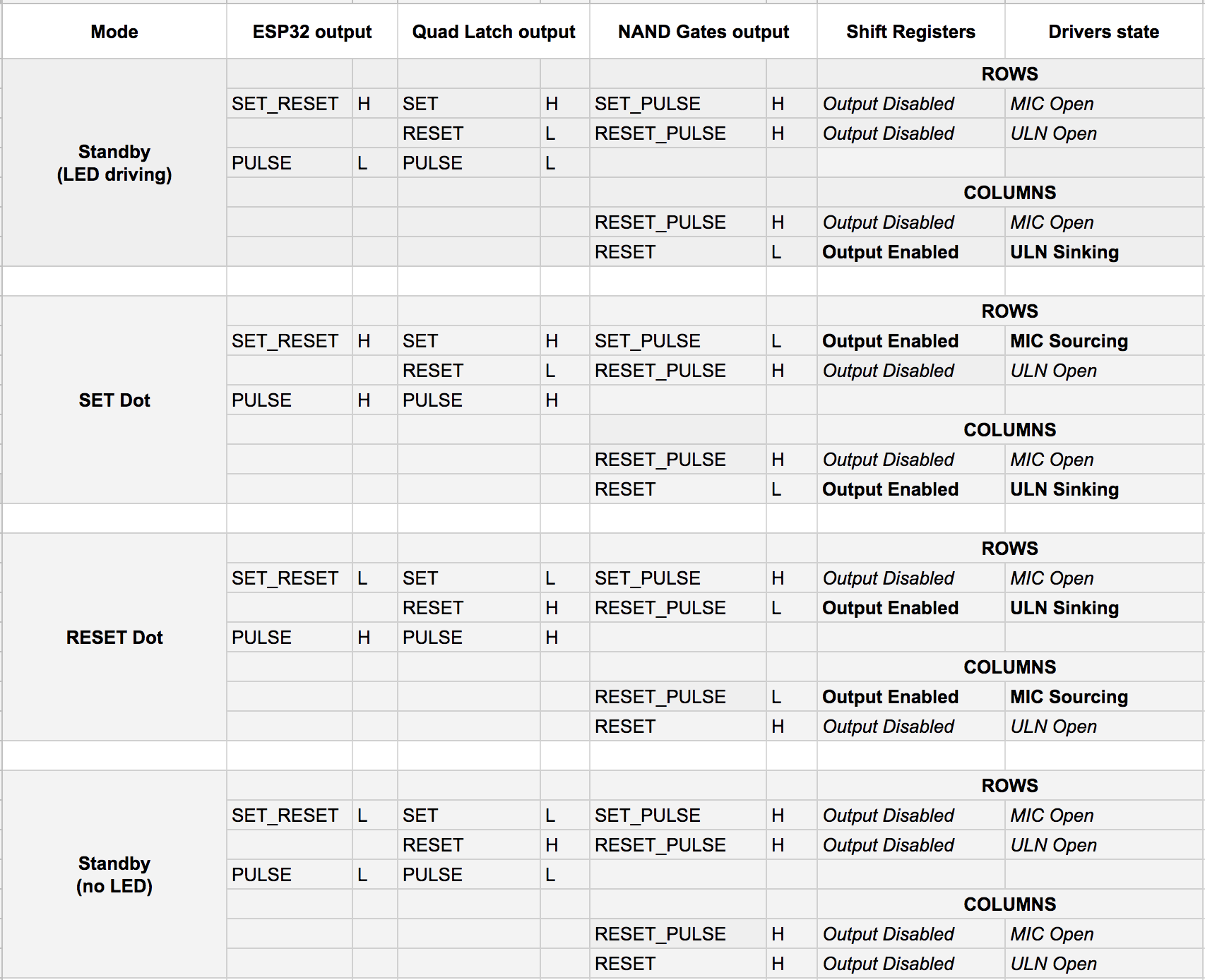

Schematic, ICs, and logic description

08/03/2018 at 10:24 • 0 commentsAs seen previously each dot is connected to three lines :

- Column SET / RESET is either sourcing current from +24V or sinking current to GND

- Row SET is sourcing current from +24V

- Row RESET is sinking current to GND

So we need to be able to Source Current from the +24V power supply, as well Sink Current to ground, both on the same line in the case of the column trace.

- Source Current with MIC2981 driver

This chip is a 8-channel source driver, it is connected to the power source, it has 8 logic inputs that control 8 high voltage outputs. When an input is HIGH, its corresponding output is sourcing power.

- Sink Current with ULN2803 driver

This is pretty much the same as the MIC2981, except when an input is high, it connects the output to ground and sinks current through it.

- Controlling the drivers with shift registers (SN74HC595)

Several solutions available here, one could use a multiplexer with a binary counter to switch from one row to the next, and from one column to the next, but for more flexibility I chose to control the drivers with shift registers. These will give me a complete control over which columns and row I’m selecting, and in any order, through fast SPI communication. If required I could also flip several dots at the same time, but power will be limited to 500mA for sourcing and sinking from the drivers.

- Quad latch for SET or RESET selection (CD74HC75)

One thing I want to avoid is to shortcut +24V to GND, which could be easily done with a simple mistake in the code such as having both the SET output and RESET output of the micro controller HIGH or LOW at the same time. To avoid this, and reduce the outputs required from the micro controller, I chose to use only one output which would be either HIGH for SET and LOW for RESET. This quad latch splits an input in two opposite signals which will restrict the system to be only in SET mode or only in RESET mode.

- NAND gate for enabling shift registers through pulse control (SN74AS00)

With this setup, the only way to control the pulse of current that goes through the dots is by shortly enabling the output of the shift registers. As we need to select which shift registers we want to switch on (either the ones for SET, or the ones for RESET), we can combine the SET AND PULSE or RESET AND PULSE. OE being active low, a NAND gate instead of AND is appropriate.

- Power sources

For the power supply, I will start with a MeanWell LRS 150-24, an open frame PSU probably overkill with 150W of power. I’ll select a final PSU when I’ll have figured how much power I need to run the display.

For the low voltage power, I found a small cheap adjustable switching PSU circuit on eBay, which offers variable output including 3.3V for the ESP or 5V. All ICs mentioned above are compatible with 3.3V or 5V inputs.

- Logic subtlety and controller available modes

If you look closely at the schematic, you'll notice that the columns sink drivers associated shift registers (bottom left) are not enabled through the SET_PULSE line as we could expect, but instead directly from the RESET line, bypassing the NAND gate. This is due to the design of the LEDs on the ANNAX display.

The LEDs have their anode connected to the shift registers on the display itself (controlled independently), and their cathodes are connected to the columns SINK lines. Therefore, when I'm not flipping dots (PULSE line LOW), I still need to enable the columns sink lines to control the LEDs, independently of the PULSE input.

Here is a table with the 4 different modes the controller can be according to the state of the SET_RESET and PULSE output lines of the micro controller :

![]()

Frederic L

Frederic L