I went to the hardware store for a R18 piece of mirror for the bed surface, and bought ~50x that in paint, glue, calipers, tape, supplies.... Ahhh the dangers of hardware stores.

The bed of my Ender 3 was a little warped, and I had to mess with the way it's attached to get it to slide right along the Y axis. Not terrible, but it made leveling hard and for large prints the level was varied enough that I got my first print failure when trying to make parts in a batch. The glass bed is much nicer. It works without adhesive, but spray adhesive makes it easier.

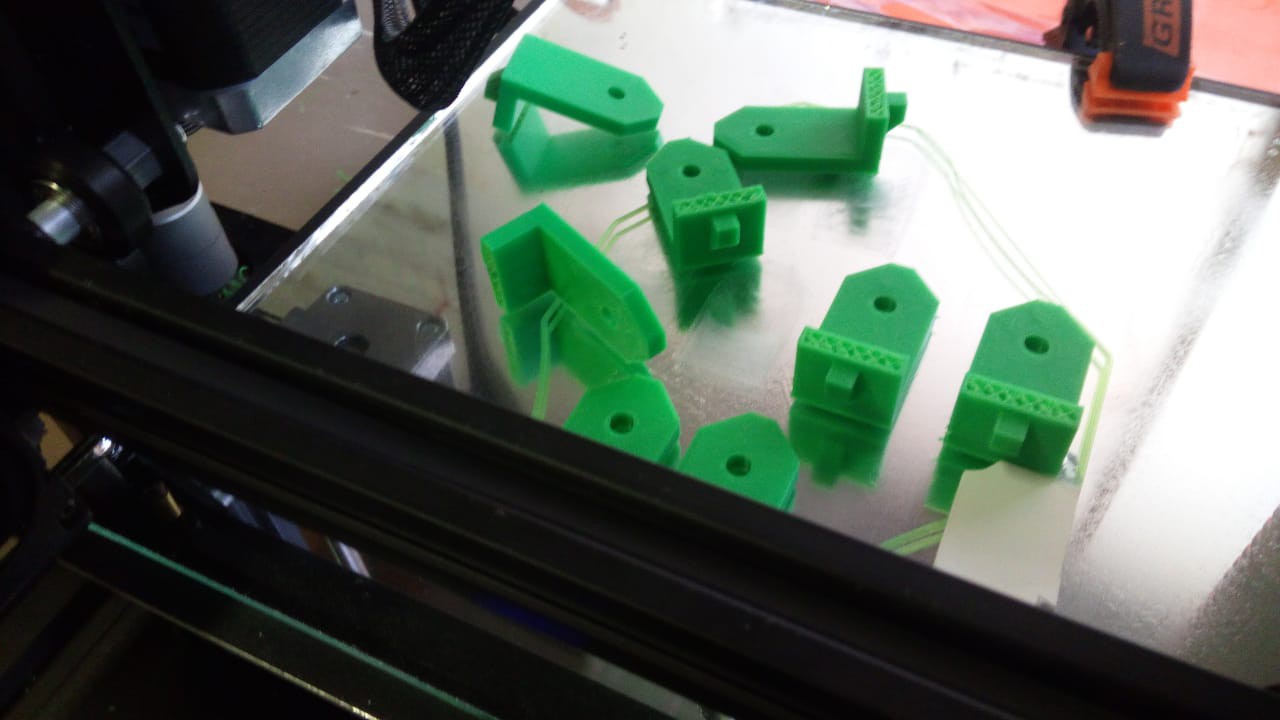

This is my first print on the bed - I got impatient and stopped it before the print was done - the rest was aesthetic and I was impatient to try other things! These parts get a paint job and some sanding, and will be used in an upcoming project. Some more pics of the parts being primed and painted, and of the final assembly with the giant base plate I printed. I'll laser cut future versions of the base, but when all you have is a 3d printer...... :)

I get a nice interference fit with 0.1mm clearance.

johnowhitaker

johnowhitaker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.