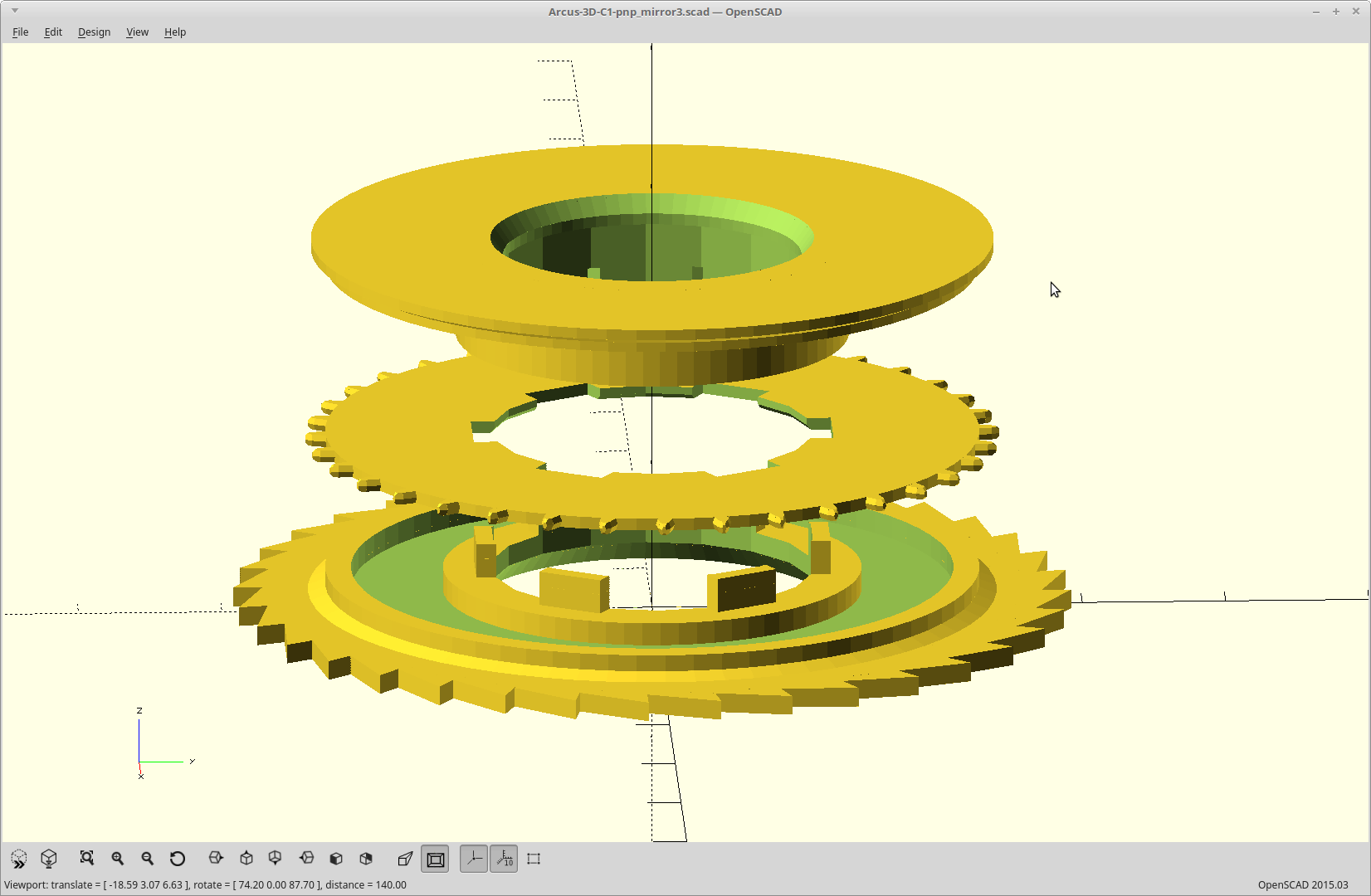

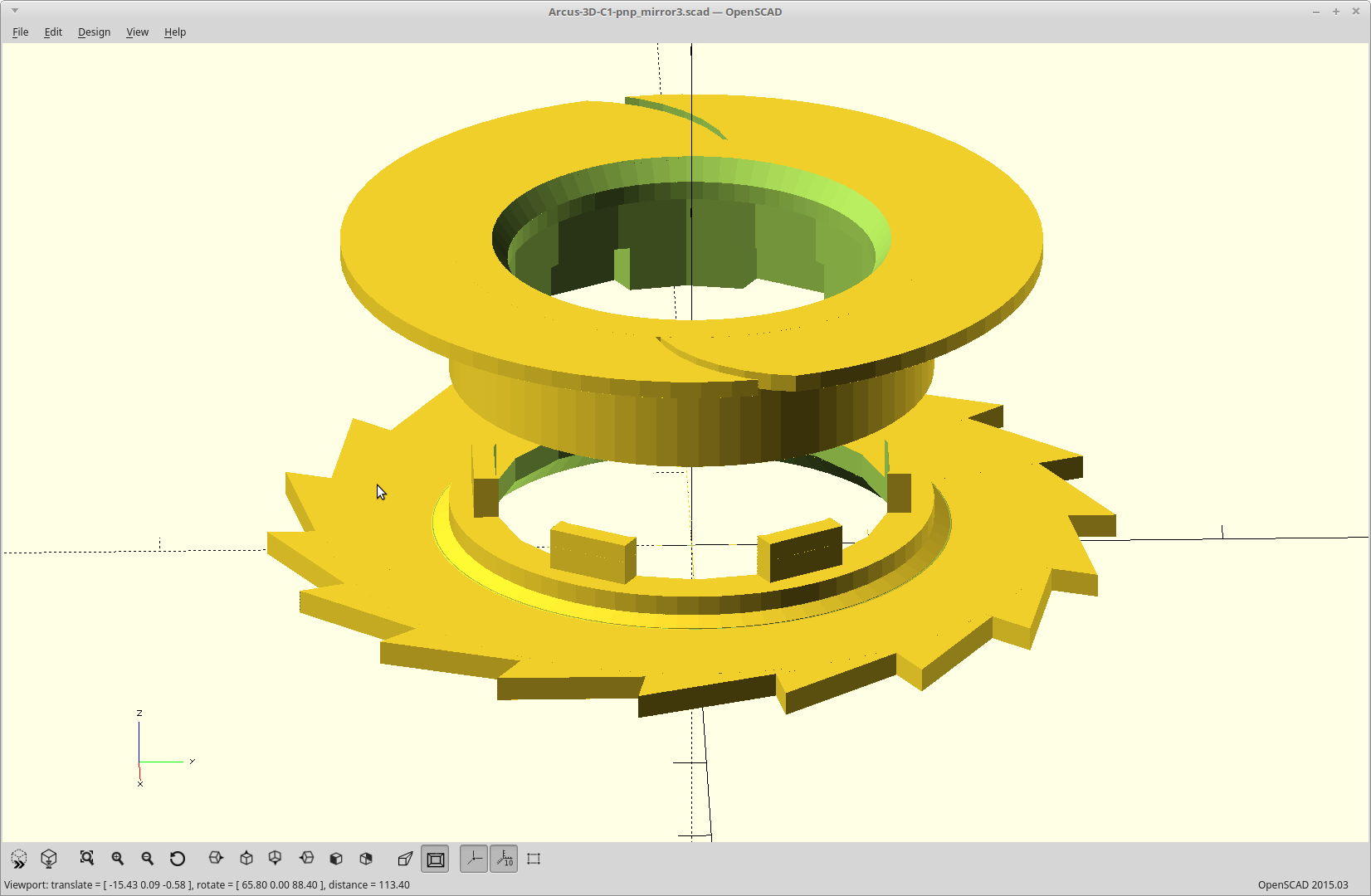

I reworked how the sprocket parts fit so inserting the bearing now locks the parts together, and added a positive stop to eliminate alignment issues. It worked perfectly.

I also took a stab at the cover tape reel. It uses the same tabs which lock the parts together once the bearing is inserted.

I was envisioning using the backwards stroke to pull the cover tape, and the release stroke to advance the tape (with a positive stop). The logistics of where the ratchet arms need to be may change this and I'm still thinking about it.

The cover tape pull needs to be a longer throw for the ratchet as the reel diameter is smaller and I had planned to exceed the necessary pull by an additional 25%. However, the ratchet driving it would be spring loaded so that once the loose tape is pulled, the spring then takes up the difference.

Or so goes the plan..

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.