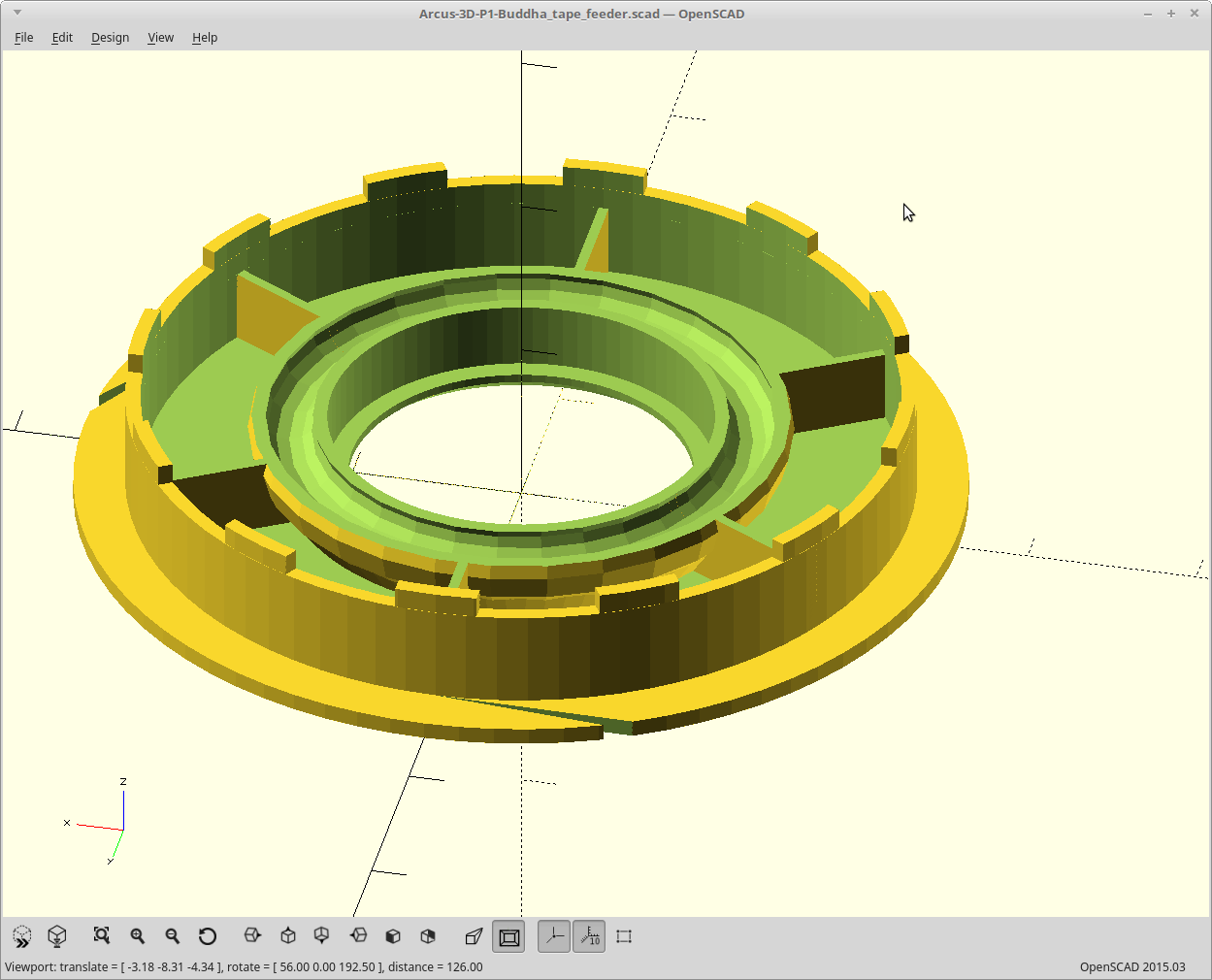

Revised the clutch so the cover idler gets more meat on the bearing. It needs to be a press fit as the hub pulling down on it is what provides the clutch pressure.

Advantage in that now it's completely obvious where the O-ring goes, disadvantage in that now you have to use the right size. Before it could handle a pretty wide range of thicknesses as it was a wedge.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.