From henceforth when I say the word LEGO, please replace that with LEGO compatible.

Getting that out of the way, I've been a big fan of the building blocks since when they were cheap(er) and I firmly believe they are part of the reason I am who I am.

Ok... mushy flashback aside, I've found a logical use for them here.

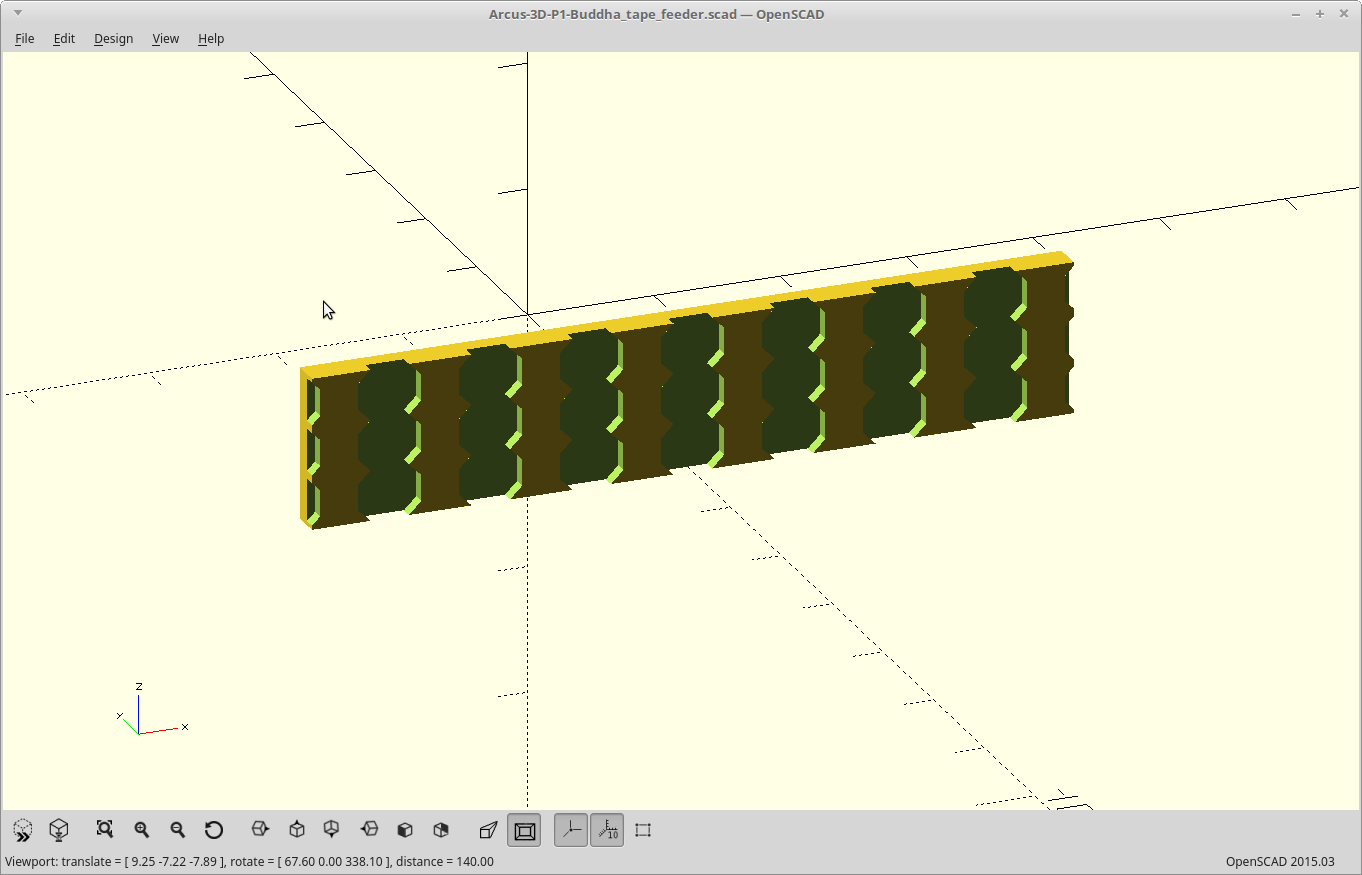

I wasn't liking the need to put holes all over my base to mount feeders. I went the laser cut route, then the DIN rail route, but then after a quick Google (yes, it's a verb now), I discovered that the dimensions of modern day LEGO blocks were exactly 8mm spacing between 'pins'.

This prompted a current quest to make a half spacing LEGO mount, so I can have 4mm spacing, which will give me the ideal mount for my feeders given any width.

Iterating on this, until it is a perfect fit, then it will go under my feeder.

EDIT: Not close enough. After much iteration, I've determined that the tolerance required for the interference fit I designed here is less than 0.05mm.

That is bound to generate significant amounts of swearing, on a 3 hour print.

I think I really need to redesign this to be a bending interface instead, like actual LEGO parts.

That still would be really hard to do as a side wall, so I think I'm going to split this into its own part and print it vertically for attachment to my feeder later.

I'll do that and print it while I'm sorting out the RC servo PWM code tomorrow.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.