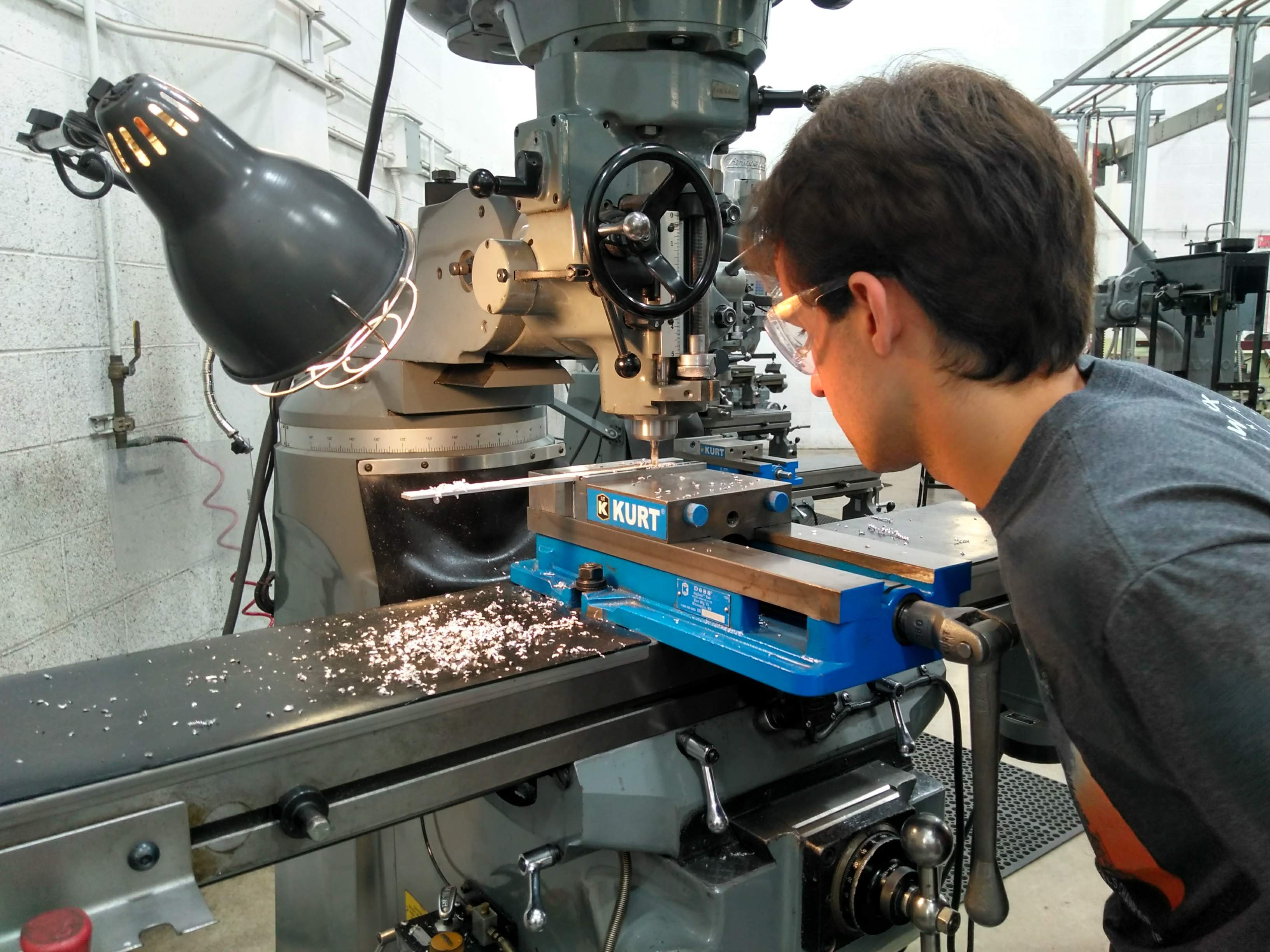

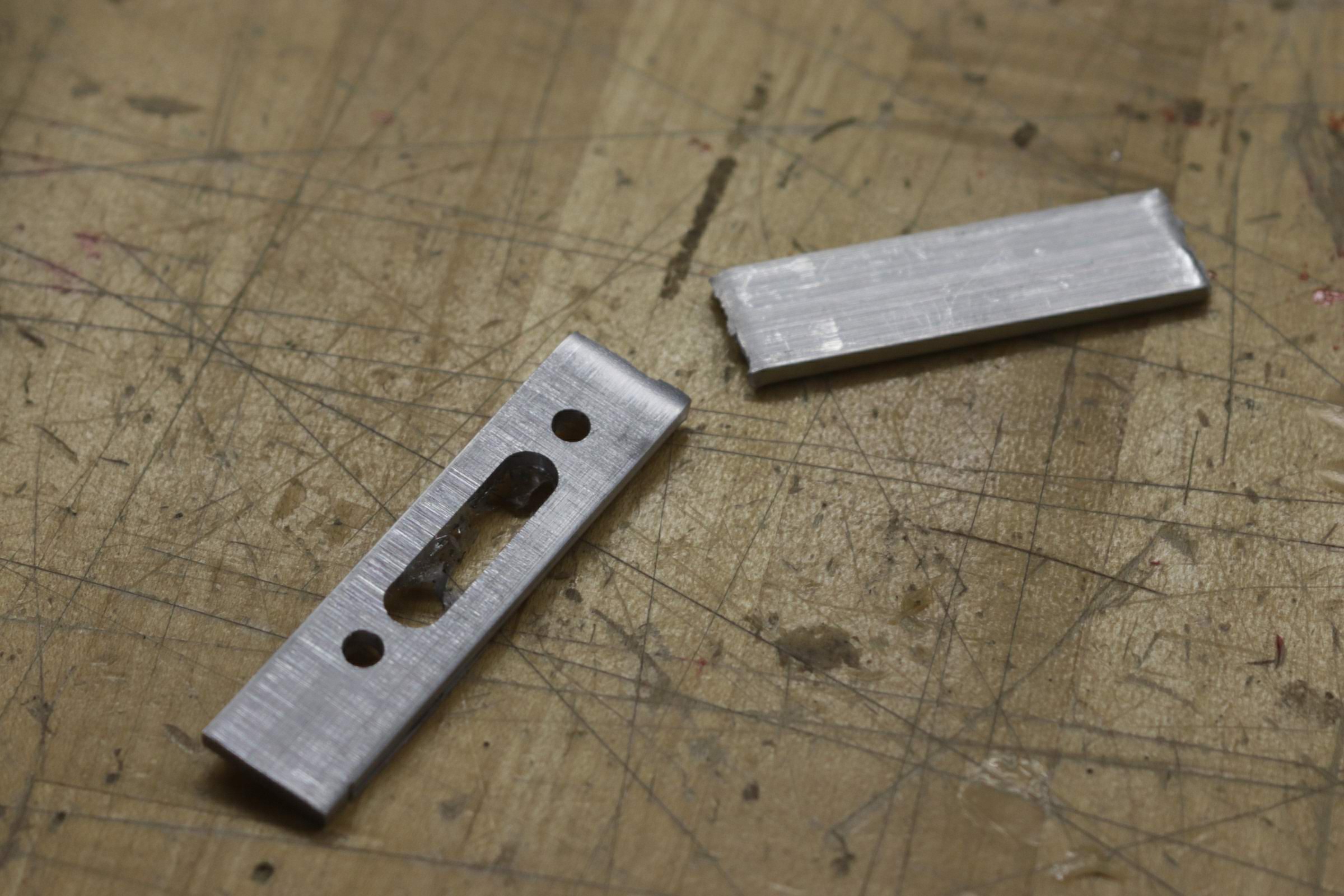

Today we went to the ASU machine shop to mill the slots in the aluminum strips and to bend them. The milling went well and we completed all the strips needed for the modules we are intending to build. However, when we attempted to bend a test part we found that the required bend radius was larger than expected. We plan to cut the strips apart and glue the front and sides on separately.

Cole B

Cole B

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Maybe you could make the bend radius you need if you anneal the metal a bit first.

Are you sure? yes | no