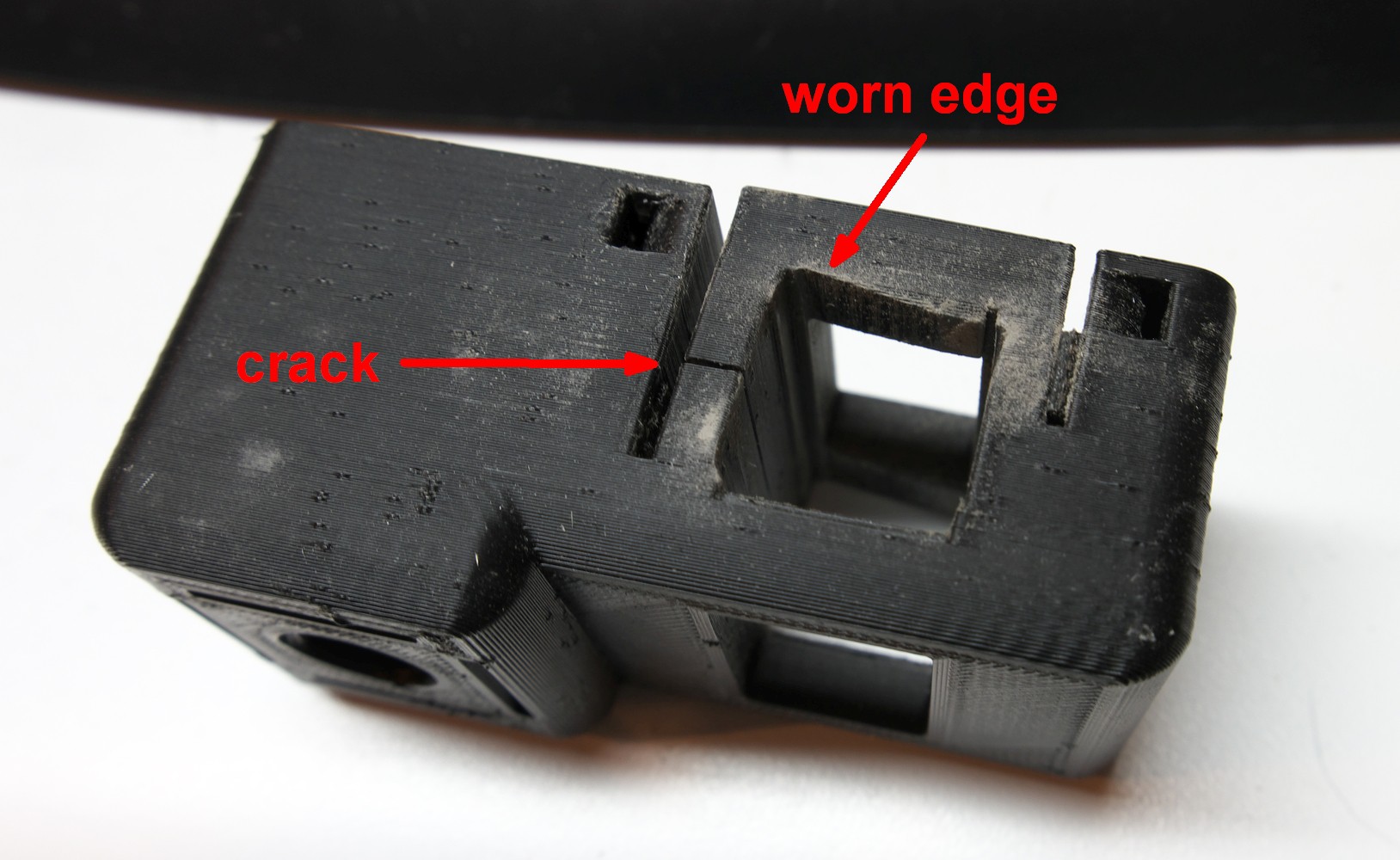

After the MakerFaire I opened up the table to check on the mechanism and found the magnet carriage badly worn. The carriage was made of printed ABS and it was sliding on a powder coated aluminum X axis guide tube. ABS/powder coating is not a good combo, and the ABS loses.

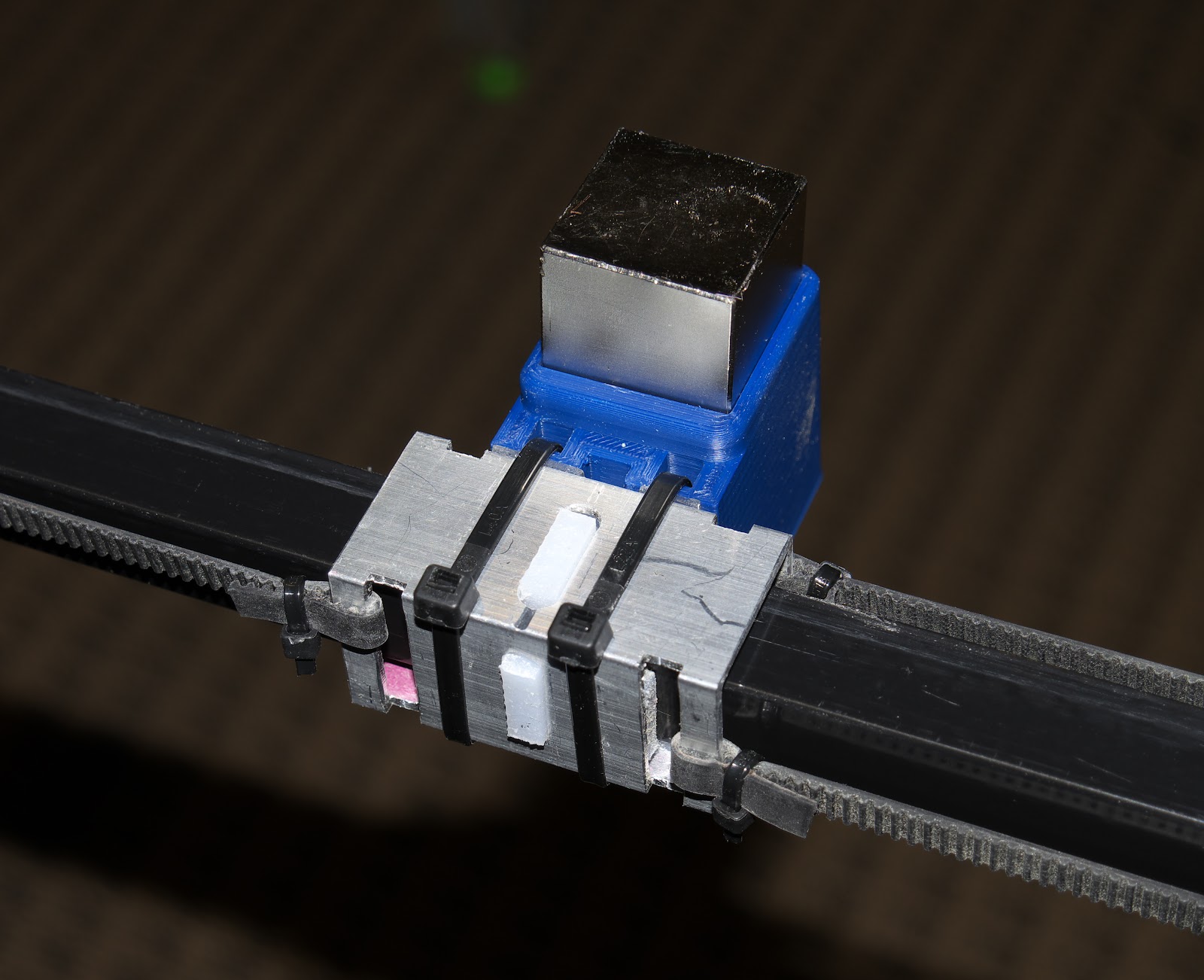

I have redesigned it to use a 1" square aluminum tube that fits over the 16 mm square X axis guide tube with room for UHMW bearings. Milled slots in the carriage tube anchor the belts and hold the bearings in place.

In this design, the aluminum takes all the belt tension force, so there's none applied to printed parts. The magnet box is held on with zip ties and can be changed easily to experiment with different magnets. It may need some indexing to prevent it from twisting. The fit is a little tight right now, but I intend to sand blast the powder coating off the X axis guide tube and I think that will loosen it up a bit. If I have to I can sand the bearings down a little to loosen the fit.

New magnet carriage design for the sand table. from Mark Rehorst on Vimeo.

Mark Rehorst

Mark Rehorst

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.