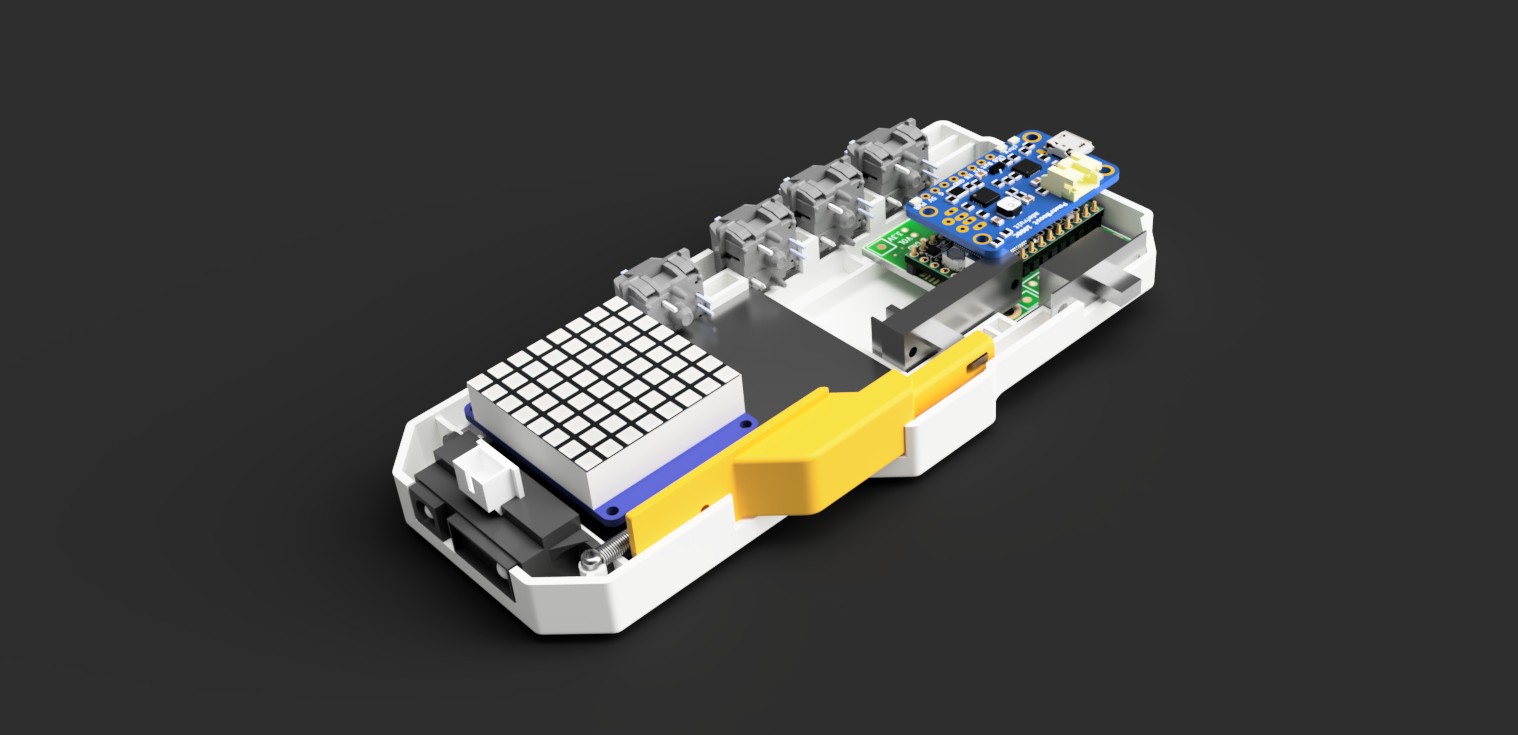

Trying to move quickly here! I've laid out my internal component structure and started shelling out the 2-part enclosure and adding mechanical mounting features. For the final design, I'm planning to 3D print the enclosure using my Wanhao Resin printer, so I thought it was best to design the enclosure as if it were to be injection molded (ribs, bosses , etc). Going about it this way will allow me to save on resin and also prevent warping during the print process.

Some cool mechanical features that I've incorporated into the design:

- Mechanical "Cherry" keyboard switches as inputs

- A springloaded linear pot with trigger. Sot sure exactly what I'll be controlling with this, but it should be a pretty fun input

I'm currently printing a prototype of the enclosure's lower half to test fit my components. If everything looks good I'll move on to the upper half (this is where I'll be housing the 8x8 LED display and LiPo charger.

In the meantime, I've started breadboarding my circuit. Once I get a proof-of-concept, I'll probably transfer everything to a perf-board. Ideally, I would like to make a custom breakout PCB, but I don't know if I can afford a 10-day lead time on manufacturing!

Still a lot to do!

Check out a quick rendering I did in Fusion 360 below:

Kenneth Marut

Kenneth Marut

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.