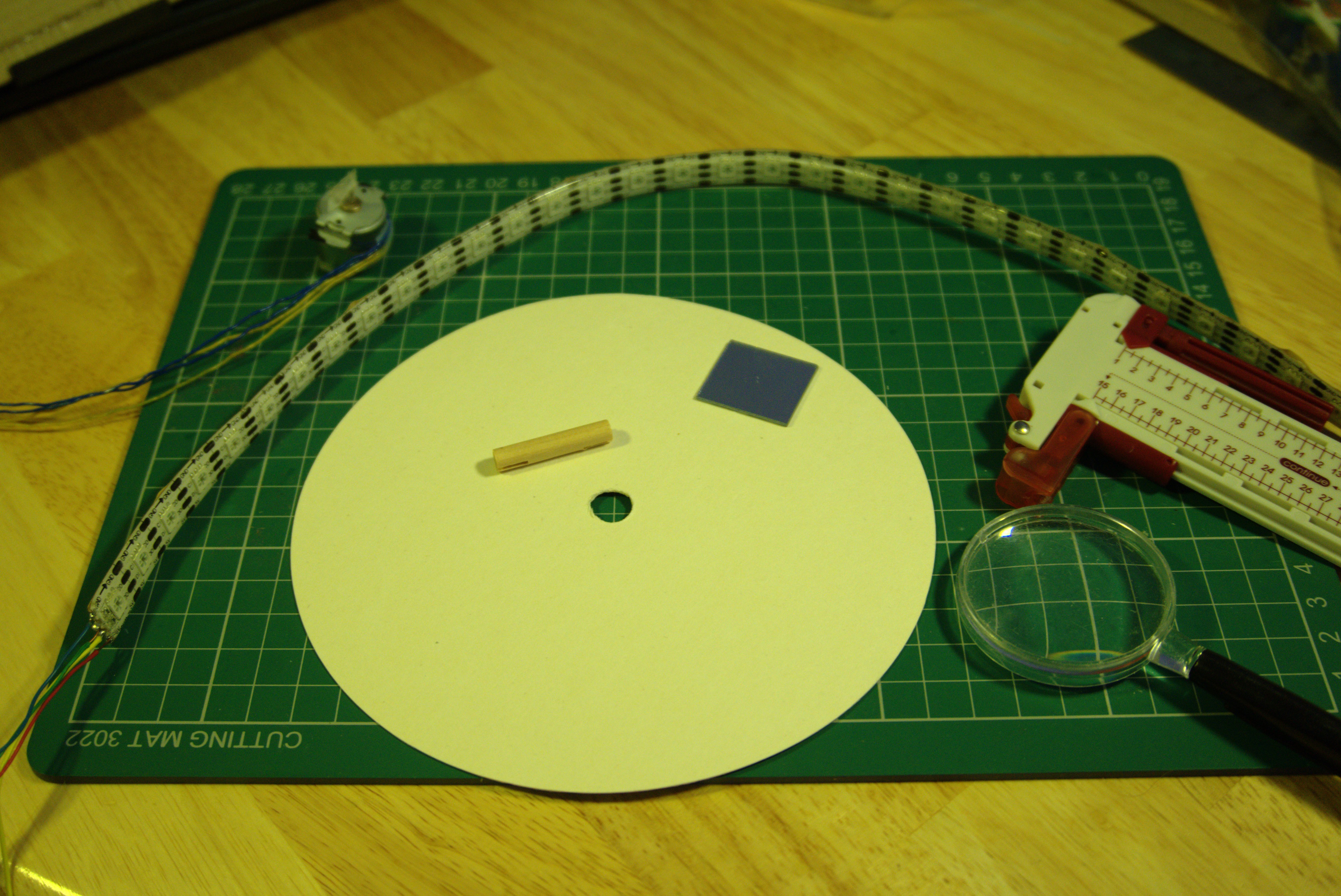

I started by measuring the length of the LED strip to figure out size of the circle. It so happened that this APA102 strip I bought on Ebay years ago had 36 LED chips. The circumference of the circle had to chosen so that LED spacing was as even as possible -- 10 degrees between LEDs. This took a bit of trial and error.

The hole in the center of the disc should be big enough to accommodate the stepper motor shaft but not too wide as the motor had to be glued to the disc.

I've soldered the wires to the stepper motor -- this is recovered from a CD-ROM drive. I had the option of wiring it as unipolar or bipolar. I chose the latter because I was going to use an H-bridge motor driver to make it spin.

bornach

bornach

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.