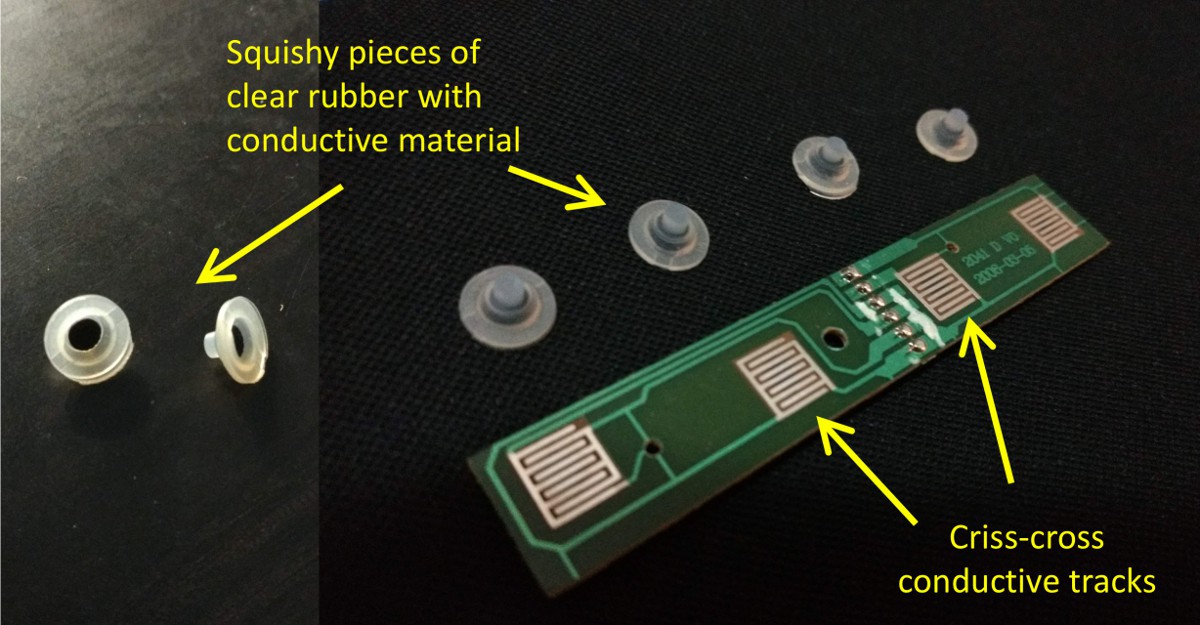

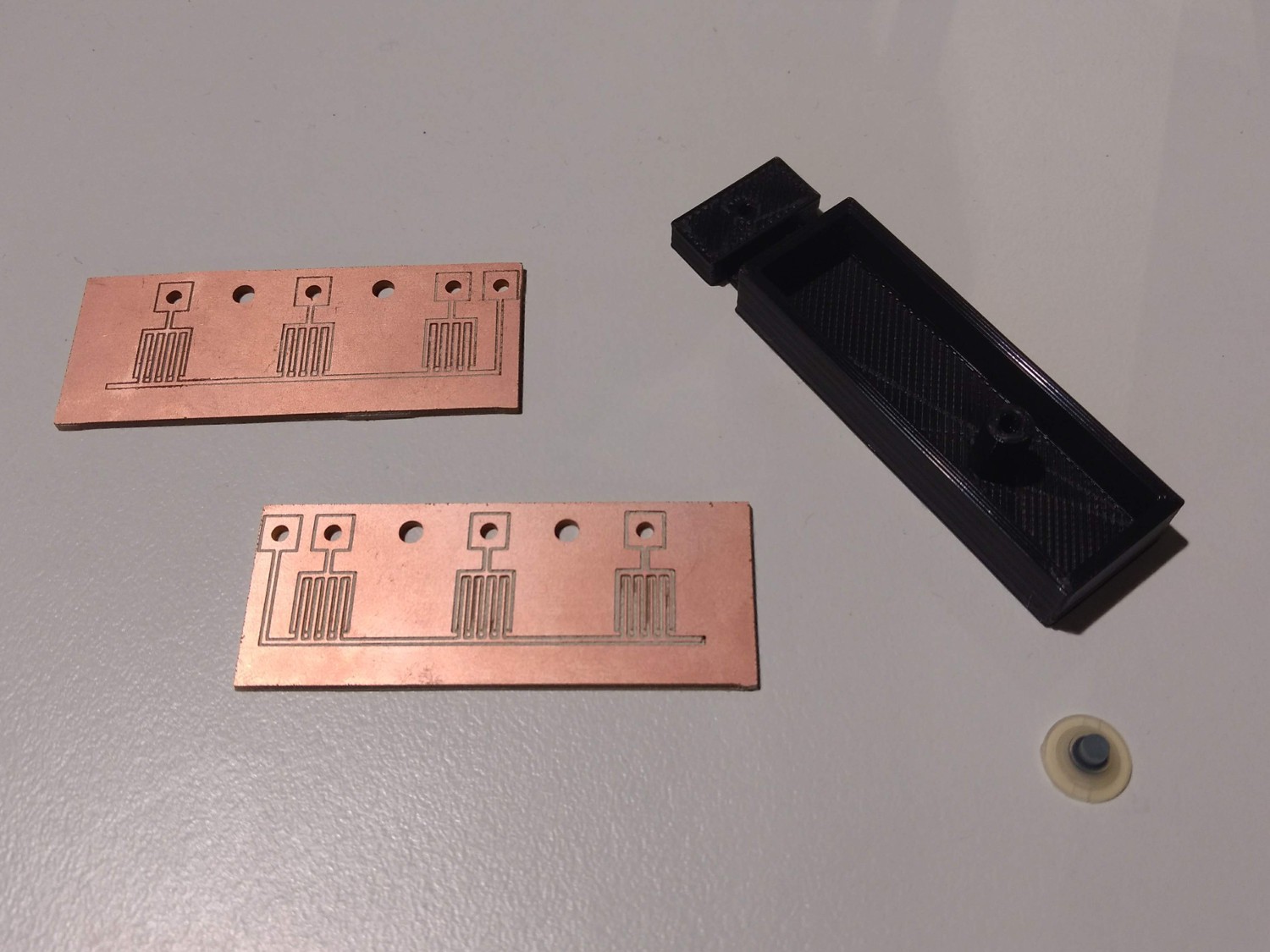

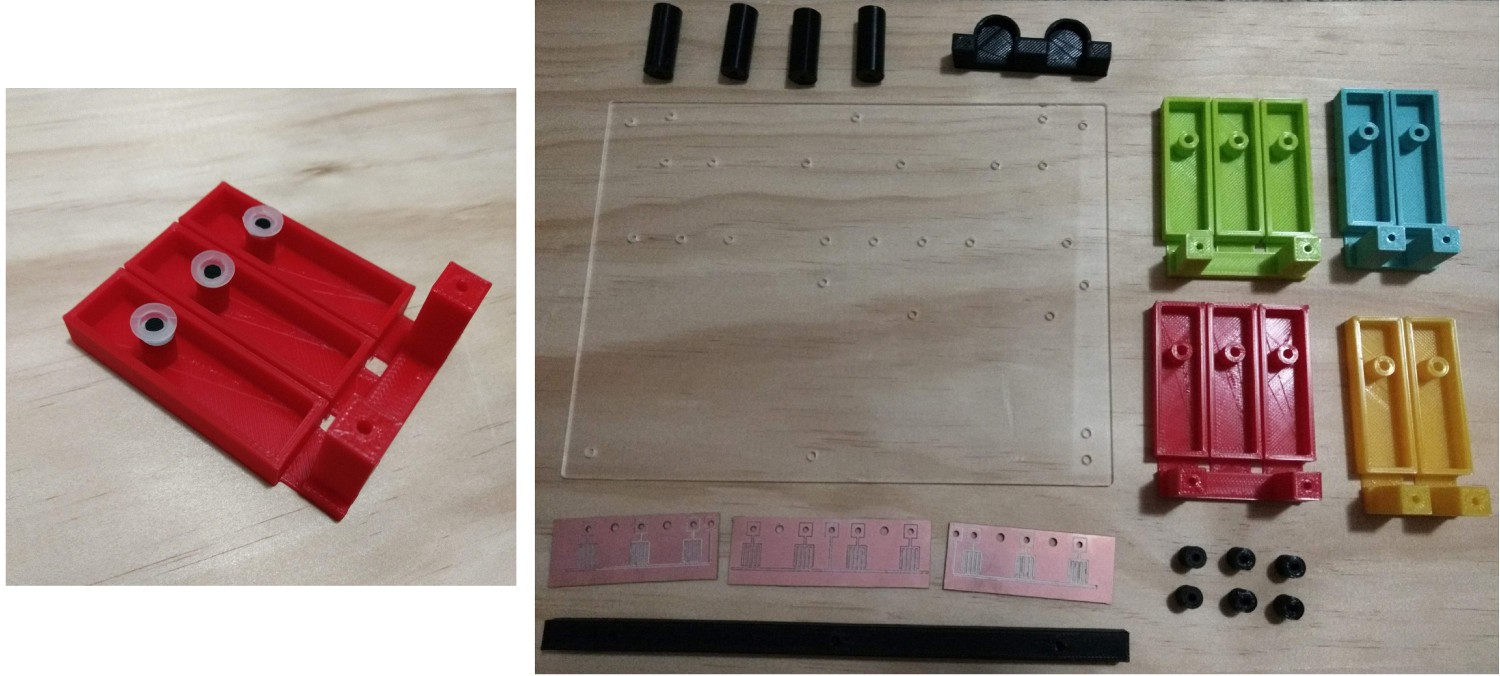

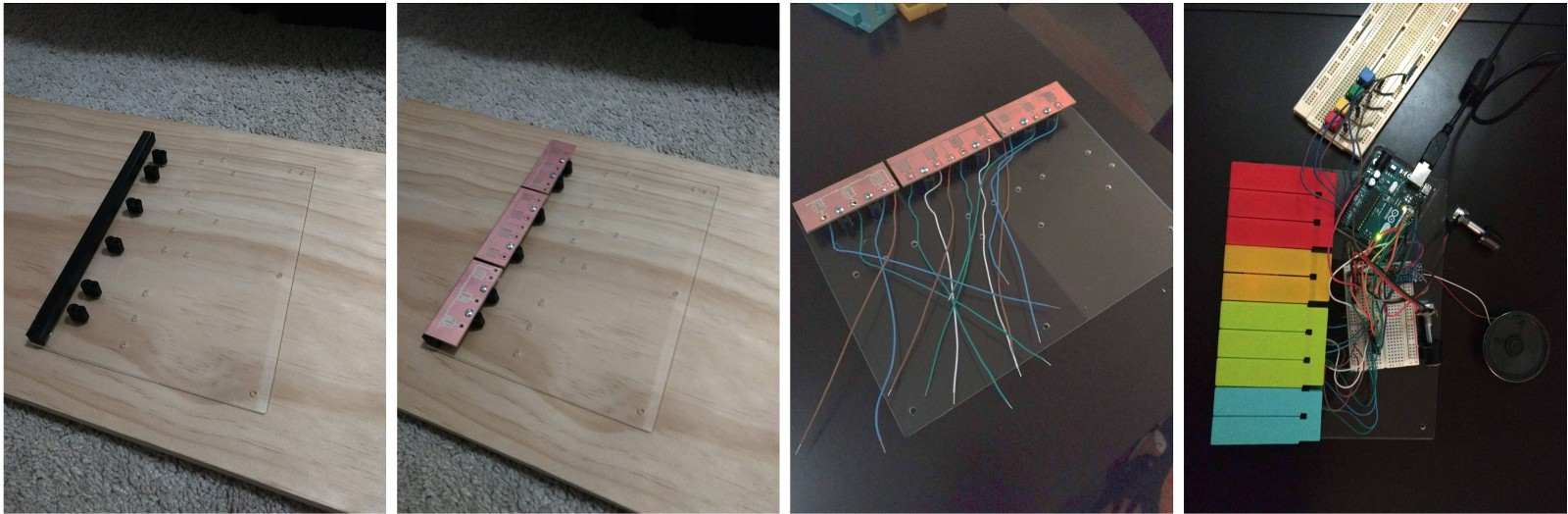

I built Pentasynth a few months ago as an experimental project around a musical instrument that could be played by people with limited musical knowledge. My local makerspace had got in some carvable PCB blanks for Carvey last year, and I wanted to try them out. I'd been thinking about making my own 3D printed keyboard, but wanted to find a better way to detect key presses than mounting horrible "clicky" switches under each key. From a salvaged toy guitar, I pulled out a bunch of these little rubber contact things that were used to drive the buttons: I carved my own PCBs to detect the switch presses and glued these rubber contacts into the bottom of some 3D printed keys I designed and made. The resulting feel is quite nice, and no clicky sounds.

I originally wanted to 3D print the whole case, but it was going to take too long, so I opted to design the case to be carved from clear acrylic on Carvey, a "soft" CNC. The case has a fairly open-plan sort of design, which gives it a bit of a rough look, but I like it. I kept the electronics connected in via a breadboard, so I'd always have the options of swapping and changing things easily in the future.

randomprojectlab

randomprojectlab

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.