Principle

The base idea is to maintain a volume of hot air around the hot-end, following its movements.

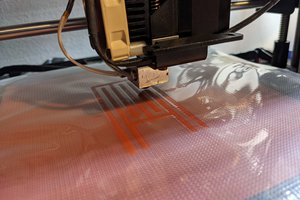

The device has a very light insulating disc (a cardboard/foam composite, fixed by three magnets on Zatsit), and located a few mm higher than the nozzle. Around him a crown without any mechanical connection with the machine, slides freely on the heated plate.

When moving in XY, the print head simply pushes the crown. In the Z direction, it behaves like a piston sliding inside a cylinder.

The volume of air between the cylindrical crown, the insulating disc, and the heatbed is always closed (with only slight leaks), and this air is permanently heated by the bed, and therefore maintained at a temperature close to it.

The object is 3D printed inside this variable volume which always encompasses it, but which moves around it.

Realization

The realization of the crown in an insulating material is not very useful, as long as one does not go up in height. The lateral heat losses are not very significant, due to the proportions of the chamber.

On the other hand, the sealing around the nozzle must be ensured.

On the prototype shown in the video, a thin sheet of PTFE was glued (with spray glue) to the entire disc, with only one punched round hole, to let just the tip of the nozzle through.

Alternatively, a piece of silicone tape, of the self-agglomerating type (for pipe repairs), glued with a thin double-sided foam adhesive can also be used.

These two solutions work in principle up to 250°C, but in practice they are more tolerant if it is accepted to change the deteriorated material if necessary.

Benefits and limitations

The heated volume must therefore, as a matter of principle, be smaller than the heated plate, and it is also limited in height, so as not to interfere with the delta mechanism.

Nevertheless, even in this ultra-simple version, it is possible to print Ø100mmx40mm parts on Zatsit, in all kinds of difficult engineering plastics, which is very appreciable! For example, gears can be made of Nylon, or POM...

It is possible to imagine doubling or tripling the printable height, by making the free crown with two or three telescopic sections.

Here is a video about it :

JP Gleyzes

JP Gleyzes

Thane Hunt

Thane Hunt

Norbert Heinz

Norbert Heinz

Dominik Meffert

Dominik Meffert