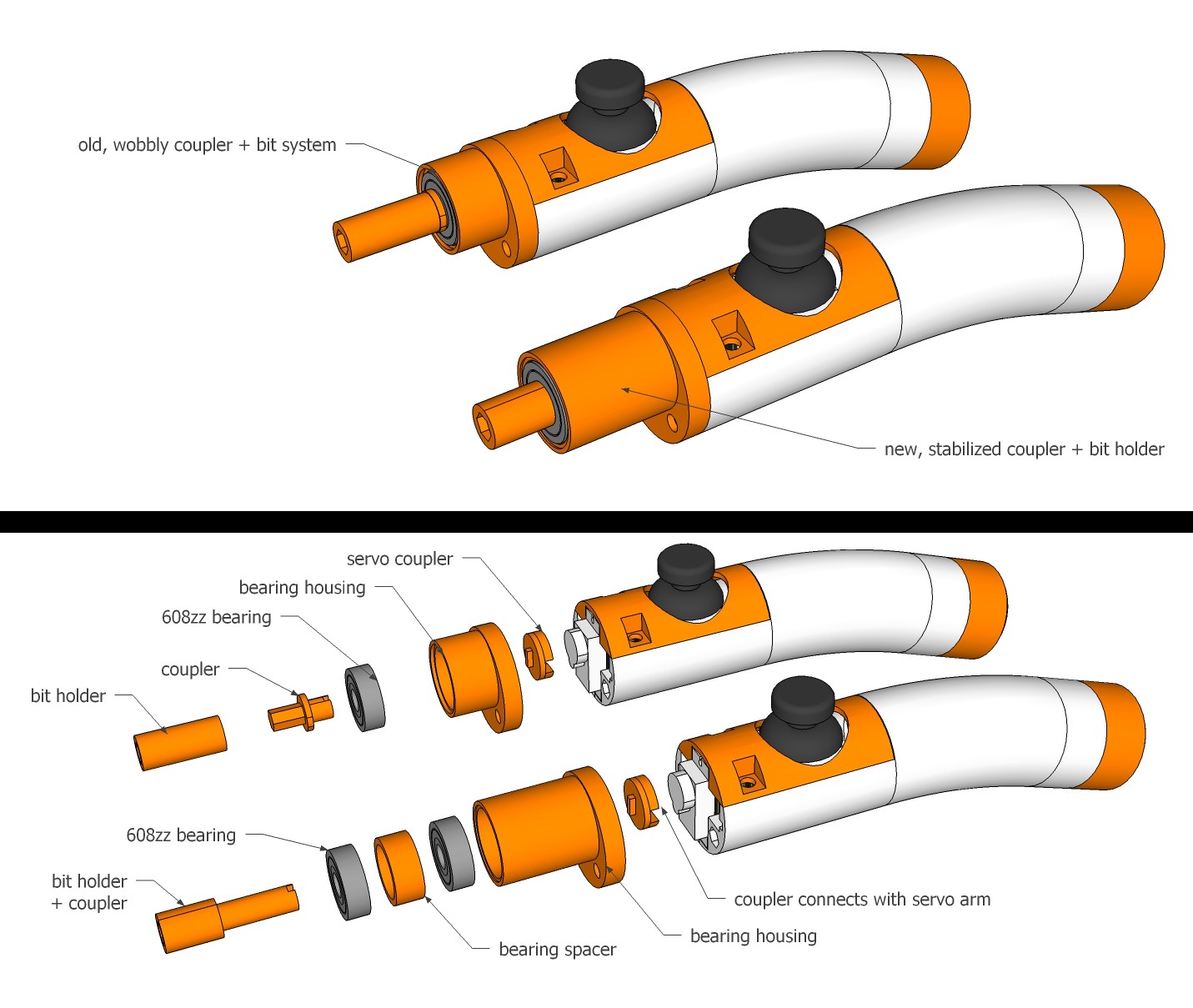

January 12, 2019 | ProgressTH The original 3D files for our 3D printed electric screwdriver depended on hot glue to keep pressure from the servo coupler and bit holder from transferring to the servo. The coupler was glued to one 608zz bearing. In theory, the bearing should have kept the coupler straight.

In practice, the coupler and bit created immense wobble to the point where it was difficult to get the screwdriver to line up with bolts we were trying to drive. Also, if the hot glue gives during use, any pressure put on the bit will transfer directly to the servo itself.

The solution was redesigning everything related to motion control:

- The bearing housing was extended to fit two bearings;

- The coupler and bit holder were integrated into a single piece and passes through both bearings before interfacing with the servo arm coupler;

- The bit holder portion of the new piece rests on the bearings. No matter how hard you push, pressure cannot be transferred onto the servo.

Now, the only wobble is from the screwdriver fitting slightly loose in the bit holder and this is barely noticeable. It is still not perfect, but at least for this application, it works well enough.

Getting perfect motion control out of a 3D printed power tool is important. For an electric screwdriver, a little wobble is acceptable. For anything moving at higher RPM's, wobble is unacceptable, not to mention dangerous.

The diagram above doesn't show the original coupler and bit holder. It shows the first try at designing a bit holder that physically rests on the bearing instead of depending on hot glue to keep pressure off the servo. It had too much wobble, prompting the two-bearing design.

Follow ProgressTH.org on Facebook here or on Twitter here.

ProgressTH

ProgressTH

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.