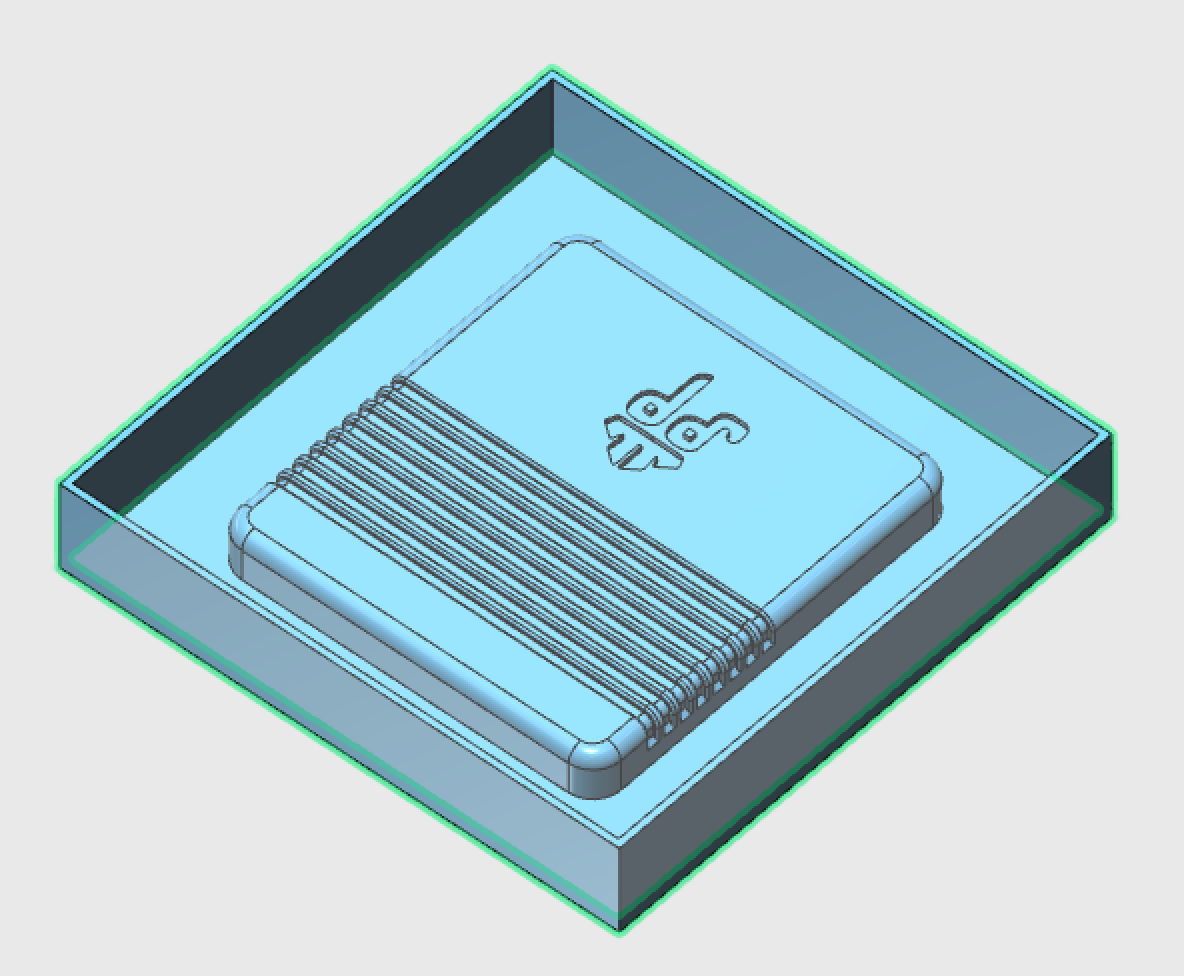

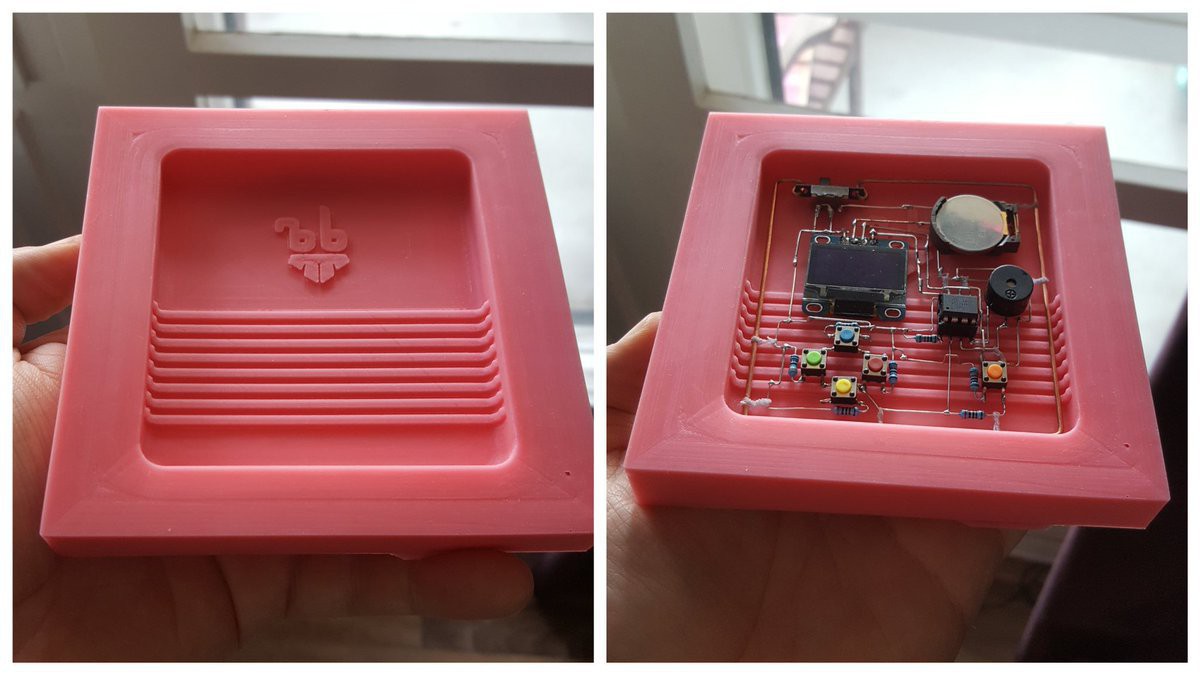

I bought a bunch of things as a result of the feedback in the video comments and what people said before that already - basically a whole set for casting stuff in resin. Then I designed a case mould in 123D Design where I would cast the negative silicone mould in. The silicone came out wonderfully, but when I tried to pre-seal the switch and IC socket, the resin got into the parts, meaning I have to resolder them. It also seems as if the ratio wasn't mixed 100% right, as the resin is still very liquid, although it has been poured 3-4 hours ago. If it is not hard tomorrow morning, then I will mix up a new batch and remove the first layer of resin to start over.

davedarko

davedarko

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Hmm, I wonder... if you redesigned the switch to be vertical and sticking out the top, like the speaker does, then maybe you could do it without any sealing of components, by just pouring exactly the right amount of resin so that the sensitive fragments of the components stick out over the surface?

Are you sure? yes | no

the switch would be poke out too far I'm afraid, as the sides are already open. I thought about using a reed switch instead. Not sure yet.

Are you sure? yes | no