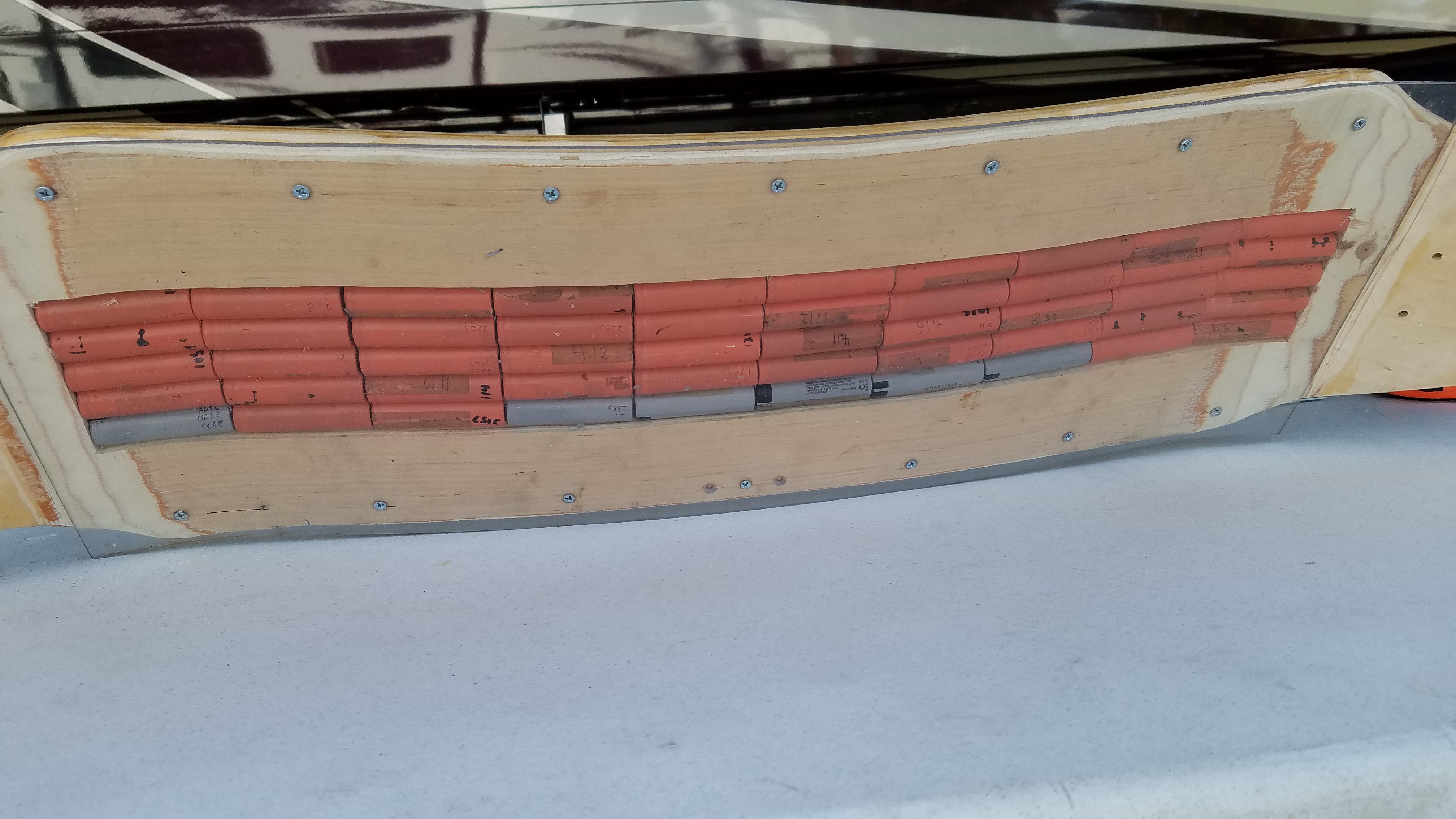

The board was just thick enough now to contain the battery, but not thick enough to leave the bottom intact. I decided to go all the way through with my battery slot and sandwich the cells between two covers. I sanded the ends of the plywood I added to ease the transition and make the top cover fit flat.

The top got a full polycarbonate cover. The bottom got a strip of it. Both were made from the old door to one of my 3D printers, so the size was pretty much set by that. If I had a choice about the size, the top would go all the way to the ends.

The bottom strip was attached at both ends, and then bent down/heated with a heat gun to make it conform to the compound curve. That part of my stock was noticeably damaged from being the printer door, so I sanded it on the underside to hide this a bit. It could use some more sanding.

The top edges were cleaned up with a round over router bit and then razor scraped/sanded. The top was a convex shape and so it kept the bend just by screwing it down. It also needs a bit more cleanup, but good enough to move on to the electronics/motor mounting.

The clear/translucent covers open up the possibility of some lighty goodness under your feet. I think I will light the underside through the cover I had to sand.

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.