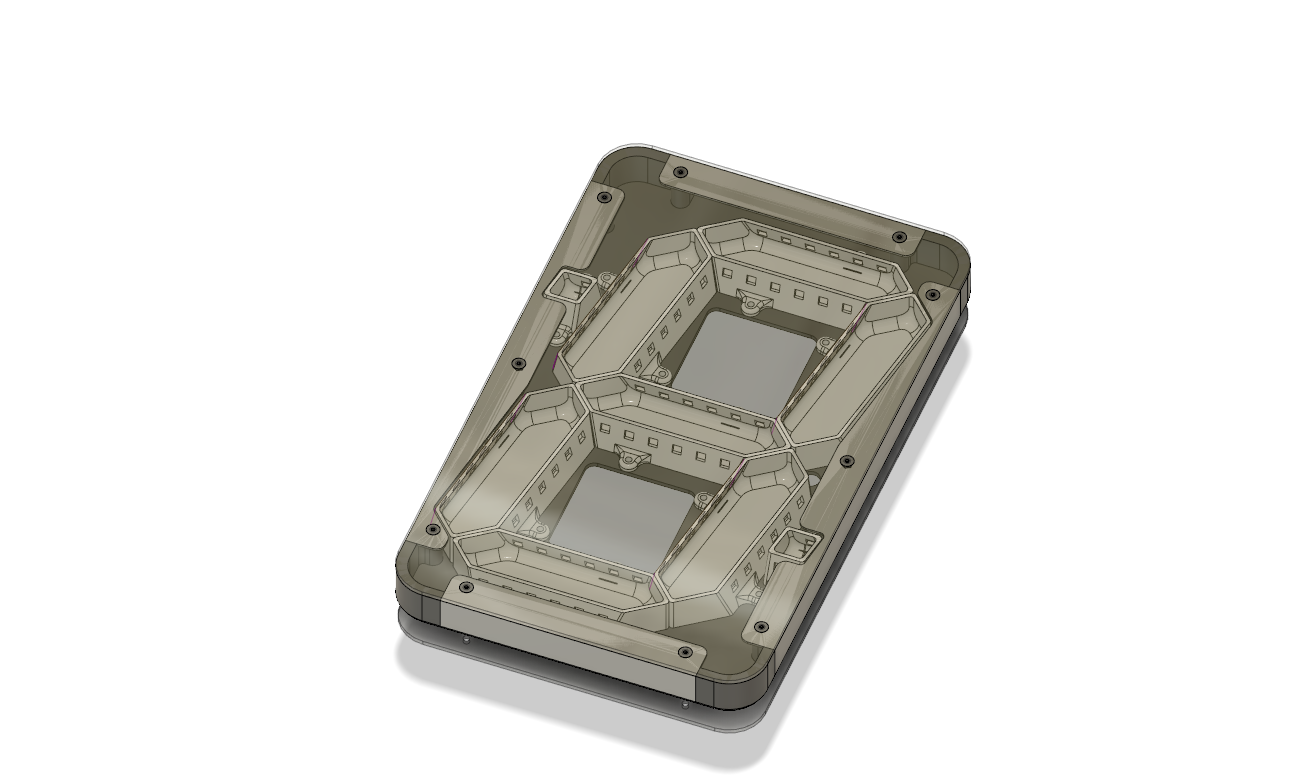

This evening I generated models for the corners and side pieces to close the edges of the sign. I'm using angle aluminum for the side walls and it attaches to the top piece. There are 3D printed pieces in the corners.

One thing I struggled with: the whole thing got 1/8 inch taller and wider to accomodate the side walls. I tried to find a way around that and eventually decided it wasn't worth it. At exactly 10x16, I had a 20x32 sheet of acrylic I could cut into quarters for the face plates. Now I can only get three plates from it. Oh well.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.