Final assembly...

Finally... we can assemble the YamPAD and complete the project.

Here's all the parts:

Here's all the parts:- PCB + aluminium plate

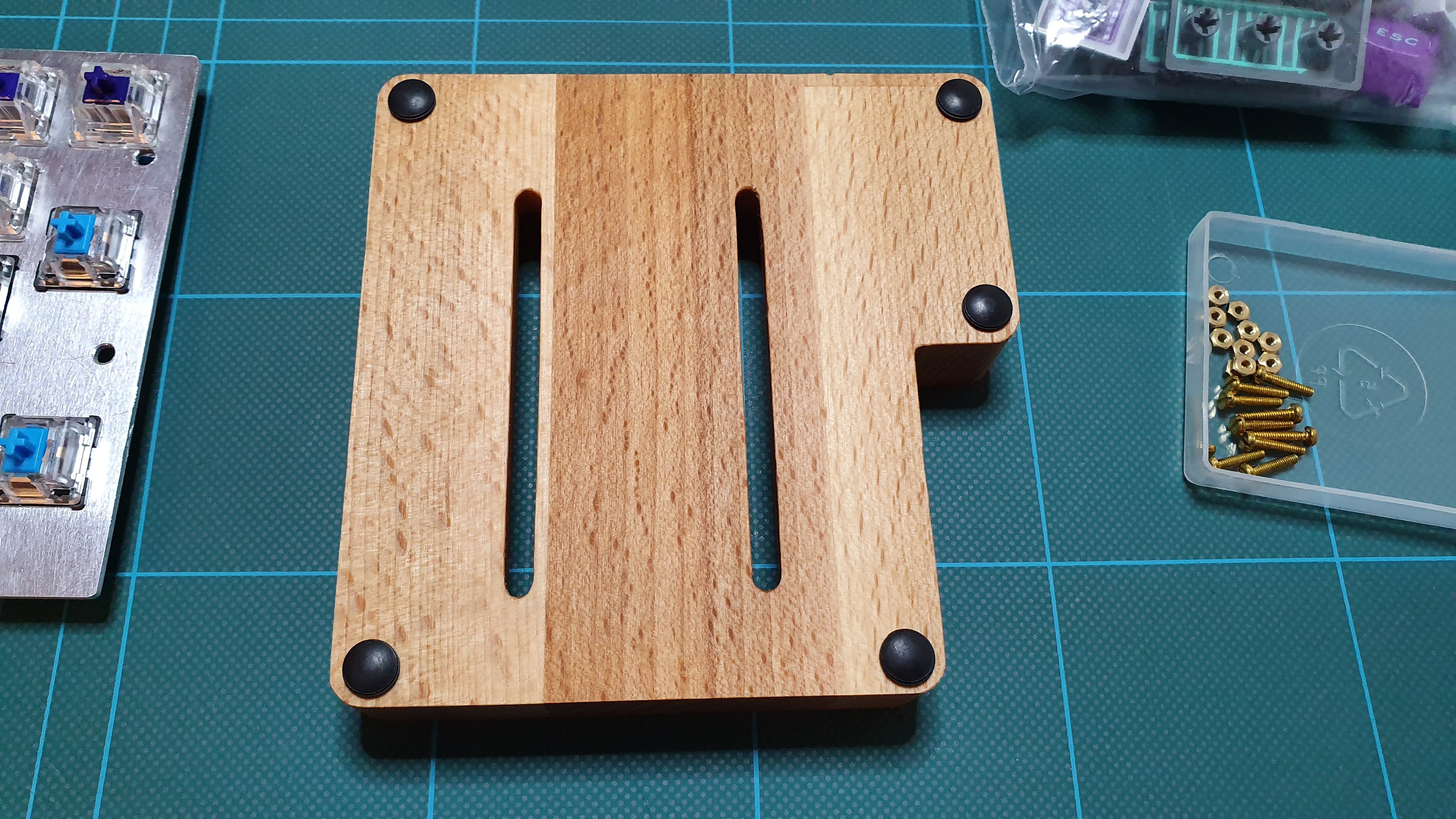

- Beech wood case

- Keycaps

- Threaded inserts

- M2 screws

Let's start by adding some rubber feets.

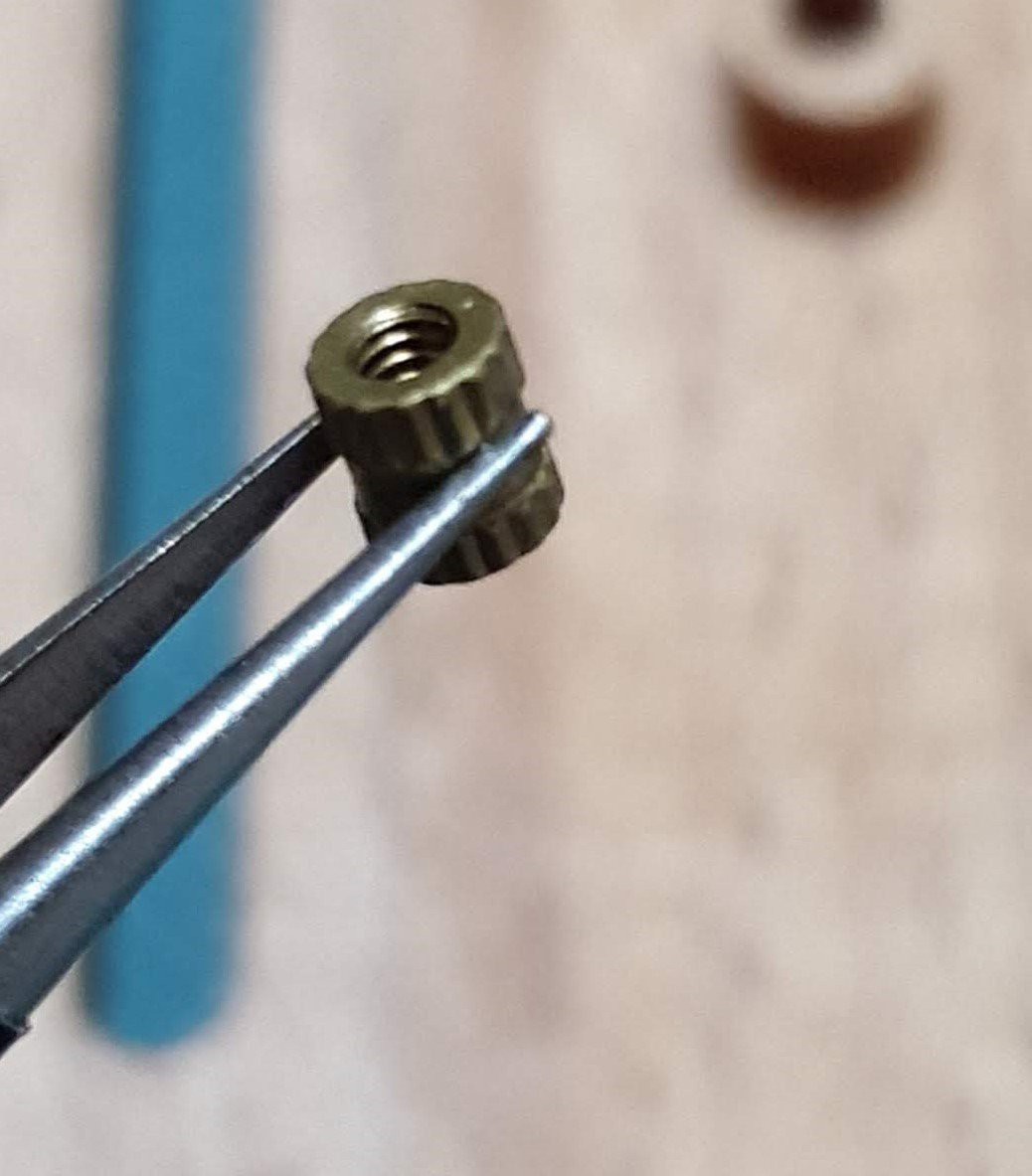

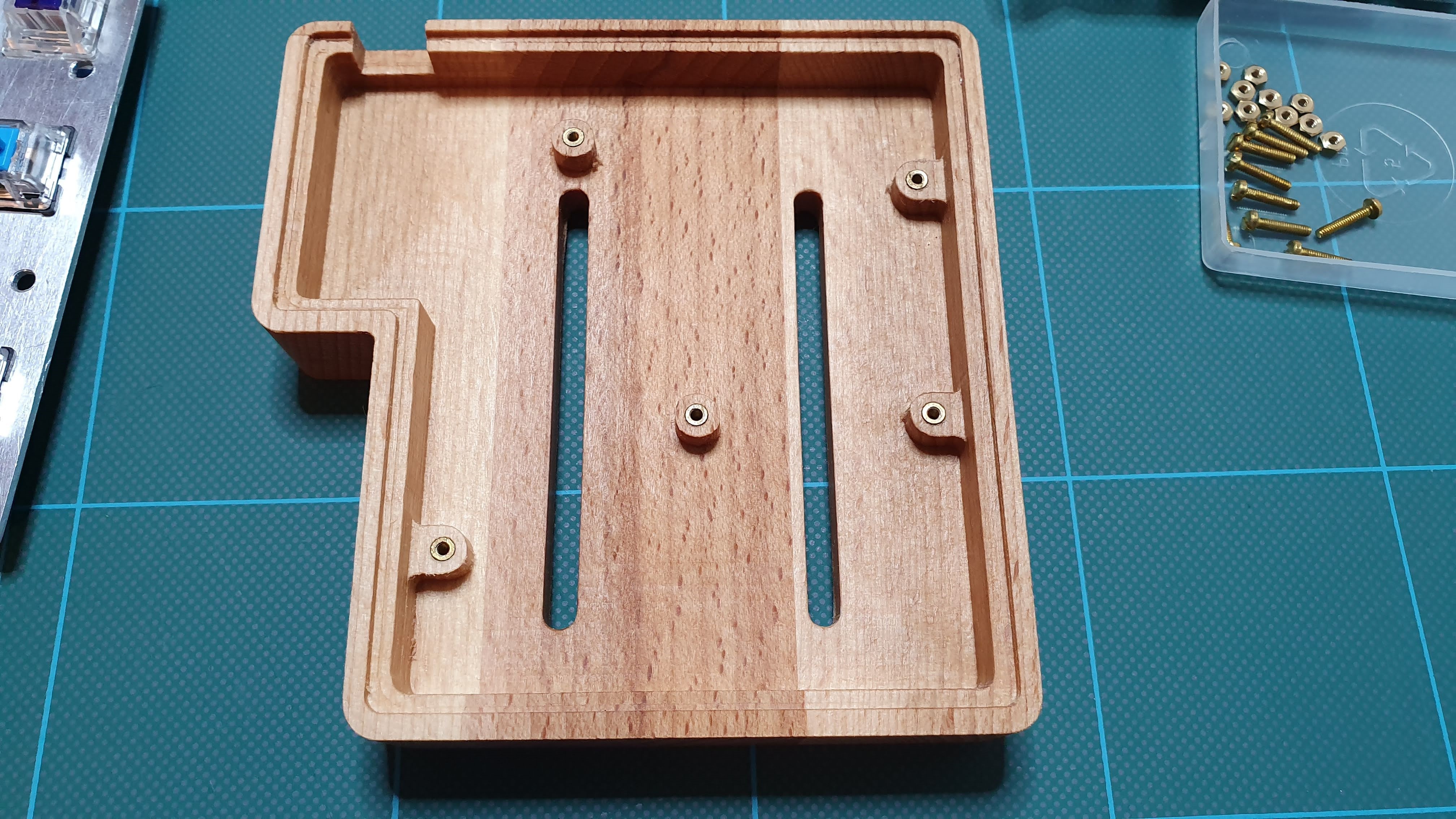

Then the threaded inserts. These are actually for plastics but work great for wood too.

Then the threaded inserts. These are actually for plastics but work great for wood too.

And now the easy part: plate, screws and keycaps.

And now the easy part: plate, screws and keycaps.

I really like the contrast between the aluminium plate and the brass screws.

I really like the contrast between the aluminium plate and the brass screws.You may wonder why all those different switches: I'll use this numpad as a swith tester to convert my collegues at work :D

Did I mention that it works too?

And now I think we can call this project complete.

Time to sum up the project. What would I do differently?

Design wise:

- I would mount the Arduino on the bottom of the PCB so that I can use the same form factor but have a nicer plate. As you can see I had to cut the plate at the top to makie room for the USB connector and there's a strip of aluminium that's way too thin on the right of the OLED screen. Just by mounting the arduino on the bottom I will fix all those problems.

- I would add the option to have one 2U key on the bottom, so that whoever wants to have it can choose to do so.

- I would add a rotary encoder because... why not?

- Enlarge the holes for the RGB lighting.

Regarding materials:

- I should find a way to protect the aluminium from scratches. During milling and related operations I scratched the surface a few time and it shows.

- I would like to wax the wood and make it look super shiny. I didn't do it this time because I was too afraid to ruin everything with a botched finish.

- I should use a thinner material for the case. Here I used a 19mm thick wood, a more sensible choice would be around 15mm maybe lower. I didn't try to fix it with the CNC because it took me 2hr to make the cut and leveling the surface would skyrocket the machining time.

Maybe I'll fix a few of these problems in the next iteration, but for now I'm happy with the results :D

Mattia Dal Ben

Mattia Dal Ben

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.