Yesterday I started the task of actually making the front plate. Since this requires that I mill on both side of the plate this required yes, you guessed it, two sided milling. Since I have not done that before this was a very exciting experiment. It starts almost like any standard milling.

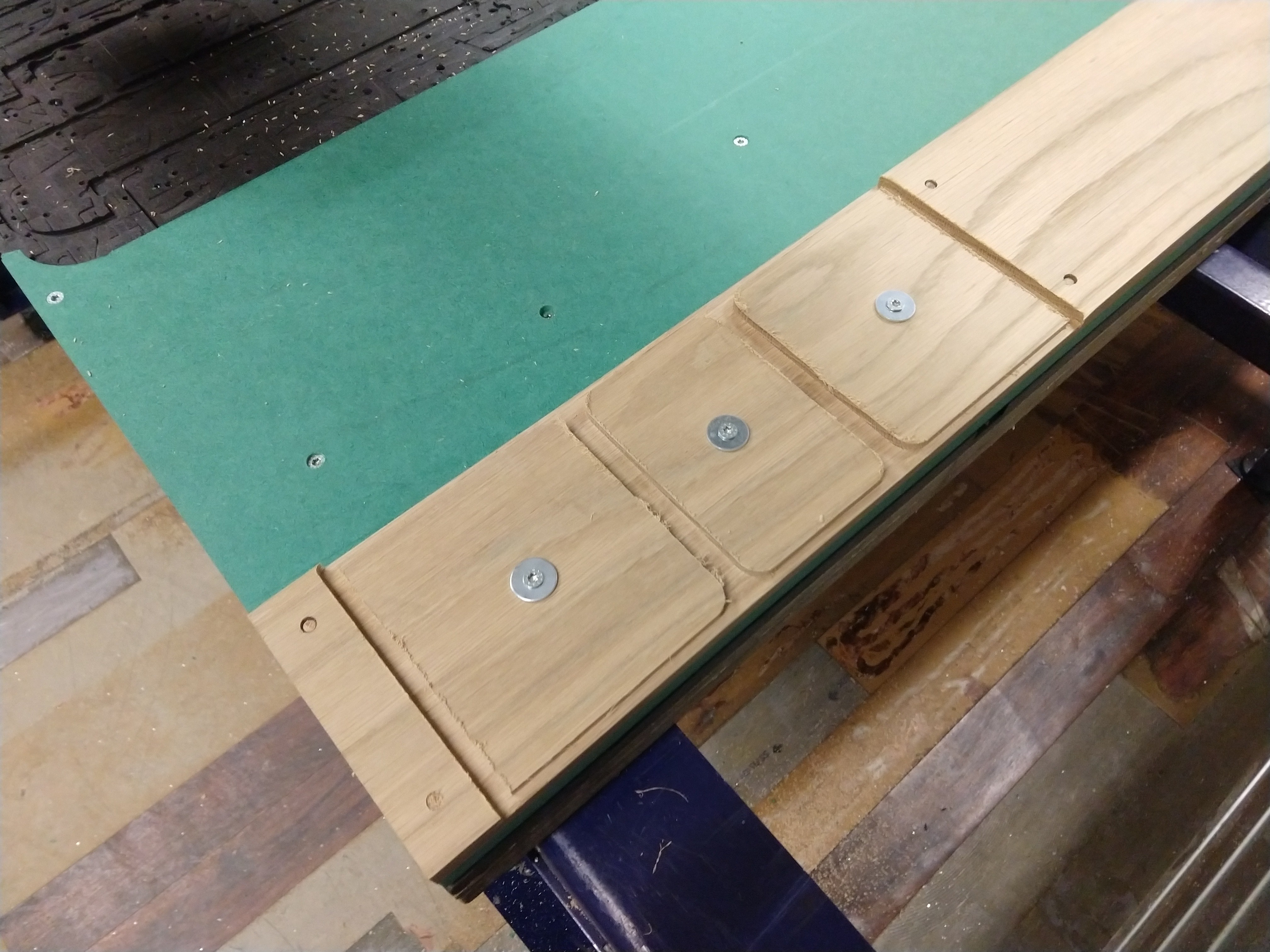

First I put on the material I am going to cut , but the first plate of material is just a second sacrificial plate. That's because I am going to use wooden dowels to align the oak I am going to cut in so that there is no offset when I turn it around.

I had learnt this dowel technique from a guy at my local makerspace. I have one in each corner outside the piece I am going to cut out of the material. This way the 6mm dowels restricts all the movement horizontally. I first tested (with scrap material) to align it with screws. This proved way be way to unreliable. As the dowels have the same diameter all the way it is a much better candidate.

First side done. Here you can see dowels and screws to restrict movement in all axis.

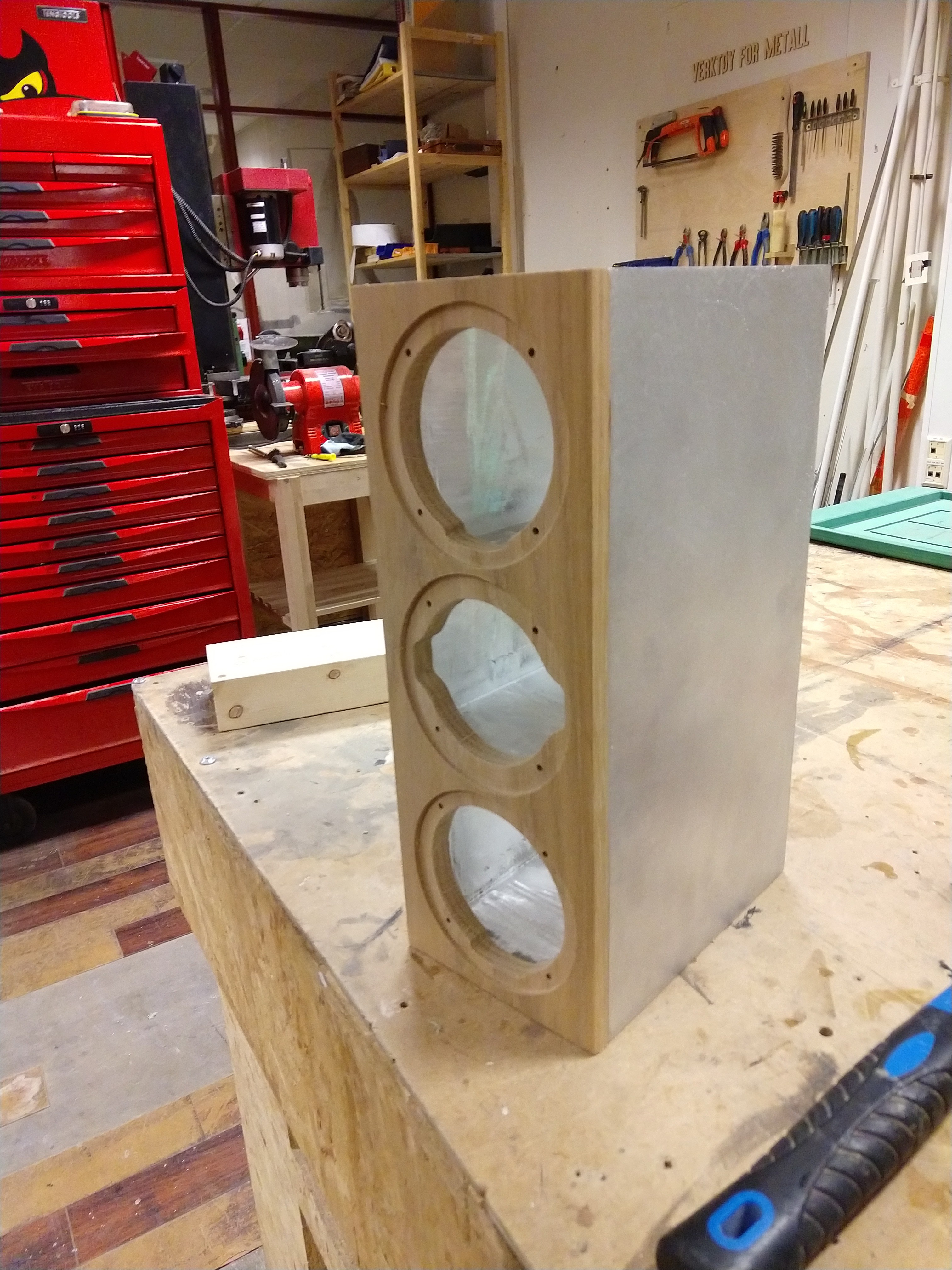

This was the nerve wracking part. Turning it around and see if it aligned correctly. I had 1 millimeter of margin on each side so precision was key.

It fortunately was within the margins! Next time I will put dowels in the cutouts for the speaker elements so it even more precise.

Temporarily mounted it to the aluminum case with a block of soft wood and a rubber mallet. Looks good!

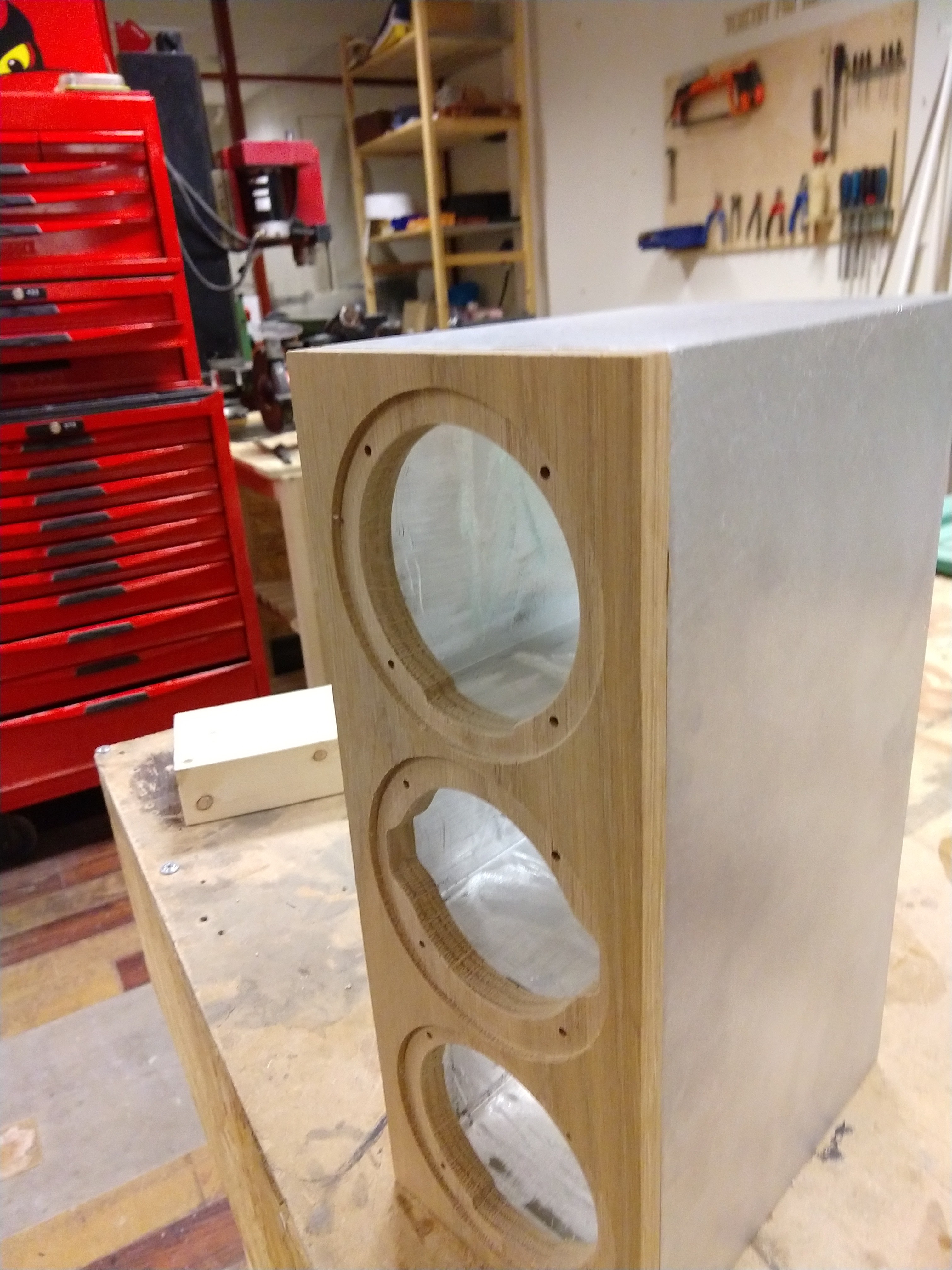

Mockup with the screws that where available from the makerspace.

Øystein

Øystein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.