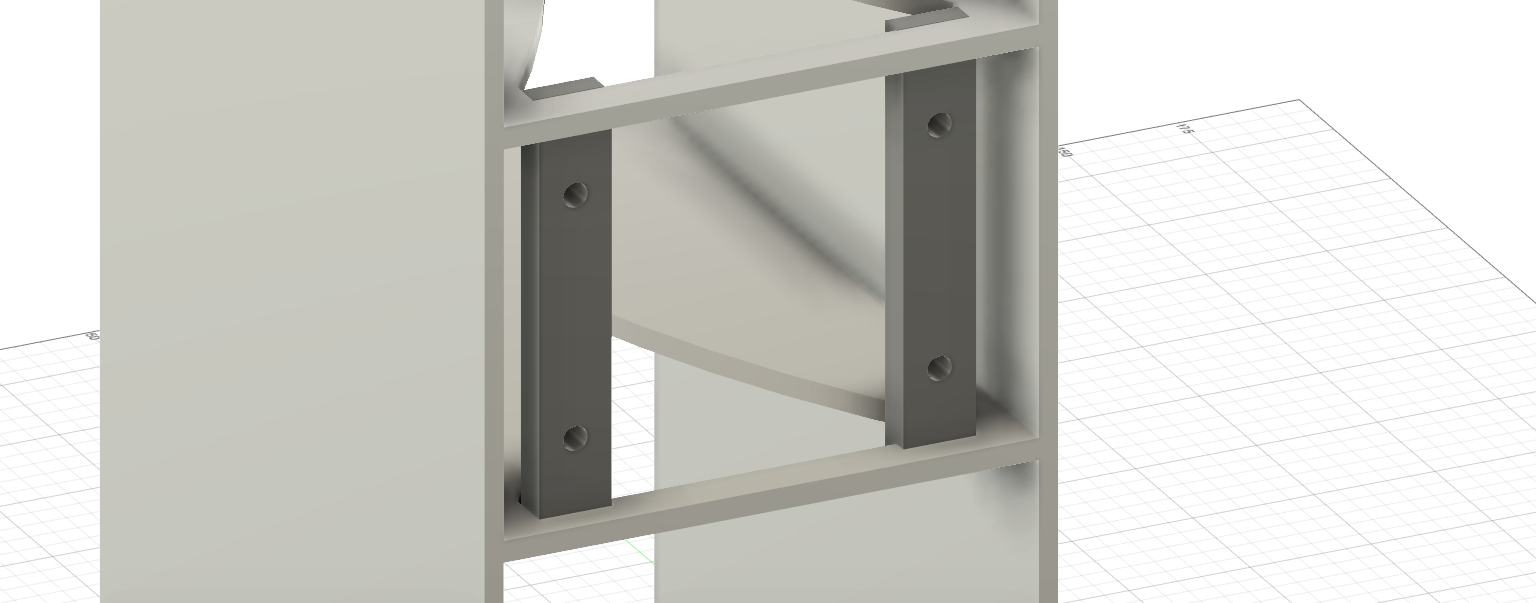

I worked some more on the bracket today that is going to hold the back plate on.

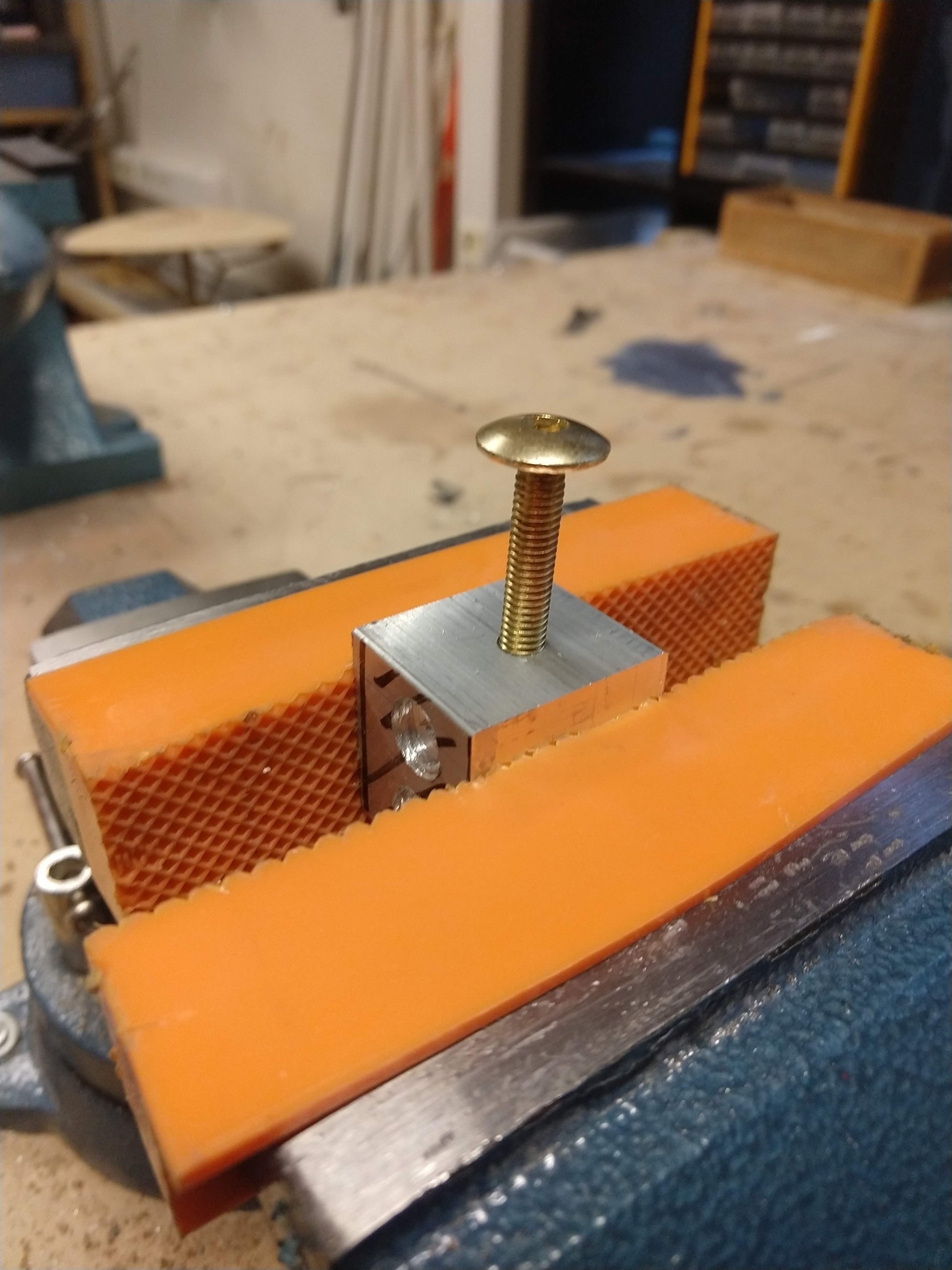

These back plate holders will be made in aluminum. It is sturdy enough to hold the load and nice material to tap into. This is the screws I am using:

I wanted something golden to make it stand out. These screws are m6 and I intend to tap threads into the brackets. I found this excellent sheet to find out what hole I needed to drill to get the correct thread.

https://littlemachineshop.com/images/gallery/PDF/TapDrillSizes.pdf

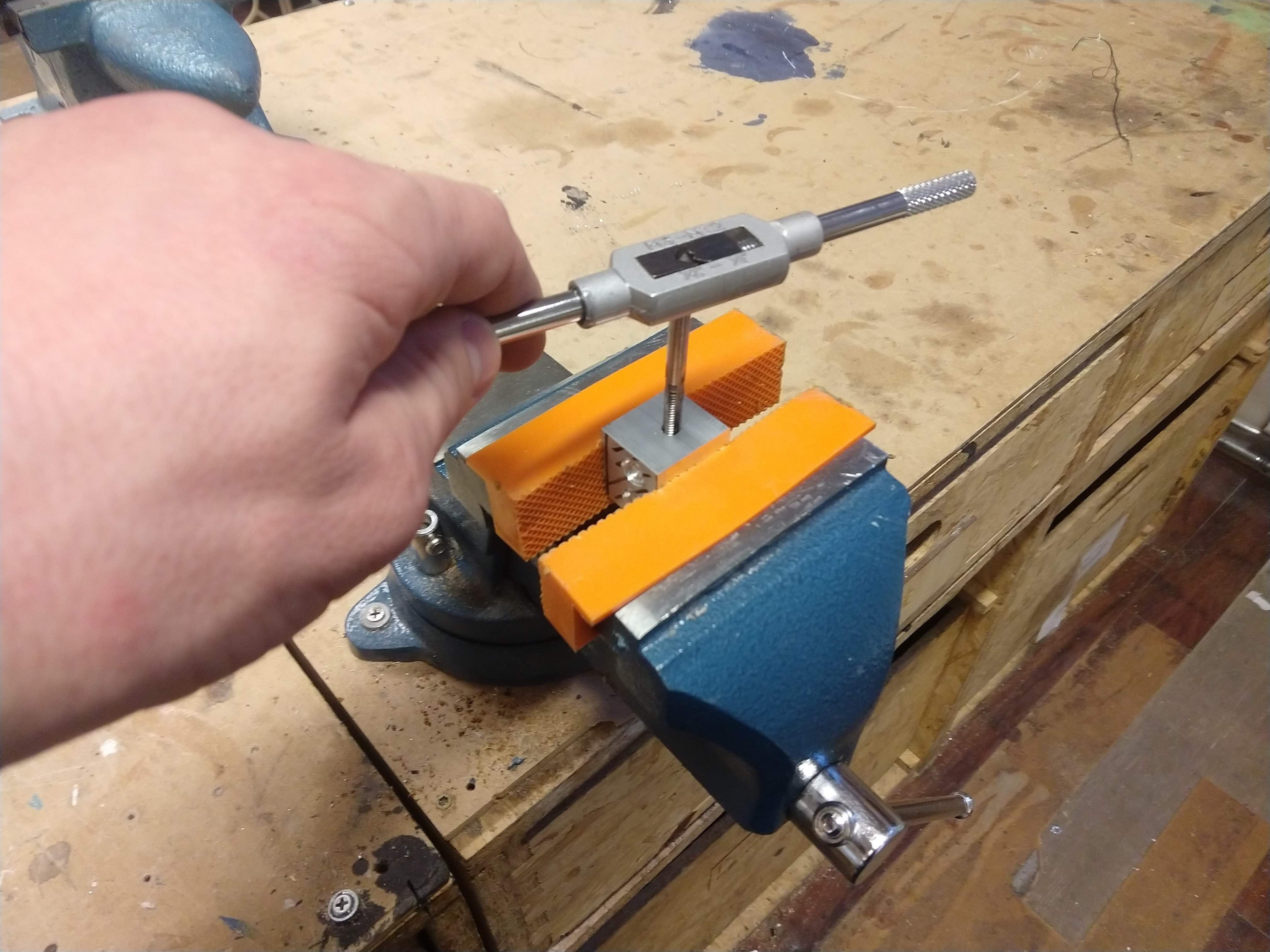

as show it states that I need a 5mm hole if the thread pitch is 1mm and 5.25 if the thread pith is 0.75. I used a thread gauge to find the correct pitch.

As I now know it was 1mm thread pitch I made a 5mm hole. then I found a m6x1.0mm tap and got to work.

It went very smoothly and was no problem using the screw.

The more I test such things the less errors I make during the machining. Hopefully.

Øystein

Øystein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.