Log about fabricated stripes and accidental capillary effect!

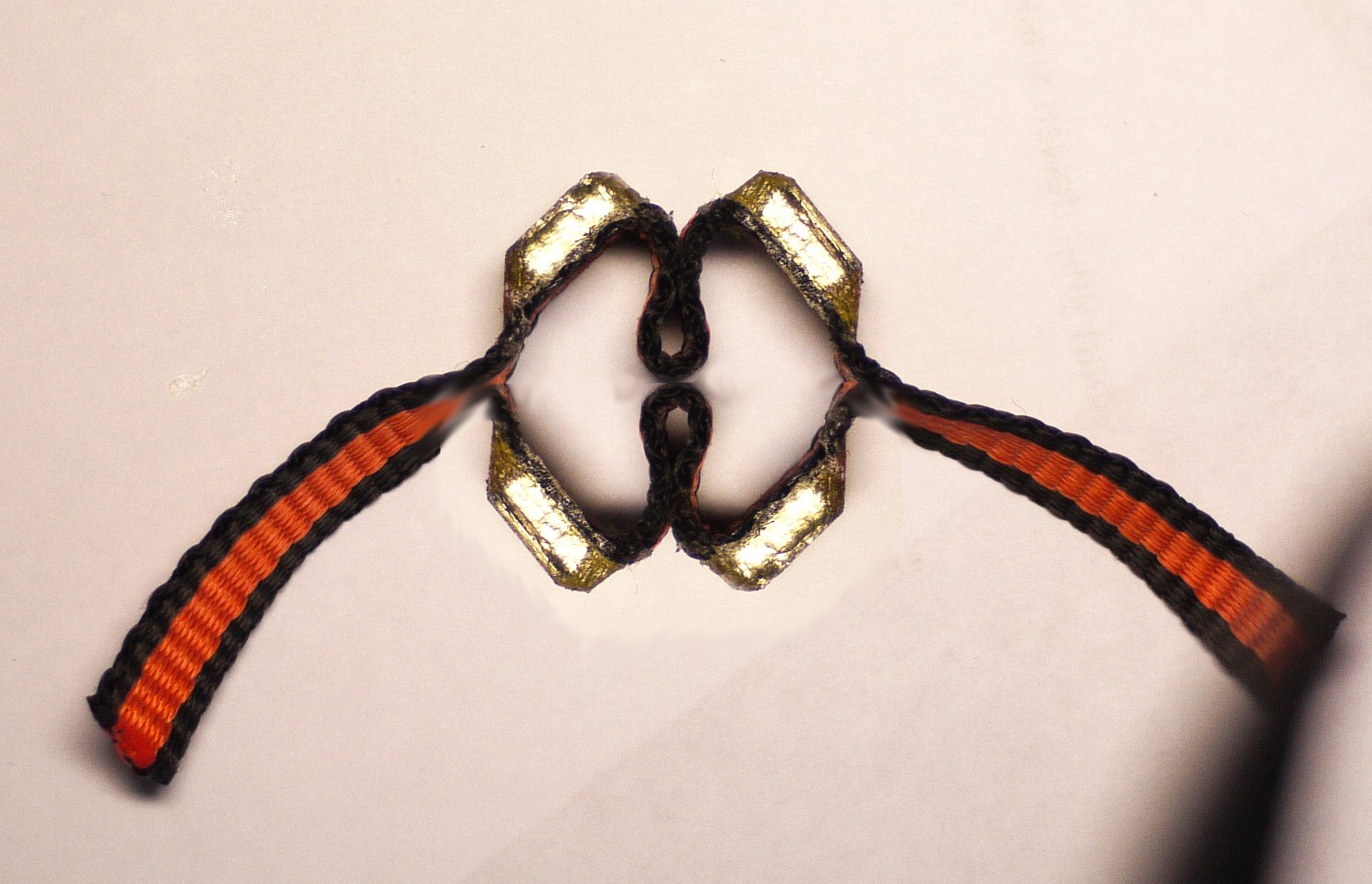

My first reaction after producing new stripes was: "H-o-w?"

My first reaction after producing new stripes was: "H-o-w?" If you remember from previous log, I predicted ease of fabrication for new structure with two big magnets. And it was almost evident for me, that if gap between sections is 30 times bigger, then it at least 15 times harder to ruin bending ability by epoxy rushing there.

And result was totally different! So I poured more oil onto nylon stripes and tried again.

Result was better, but not like previous time, with 4-magnet structure.

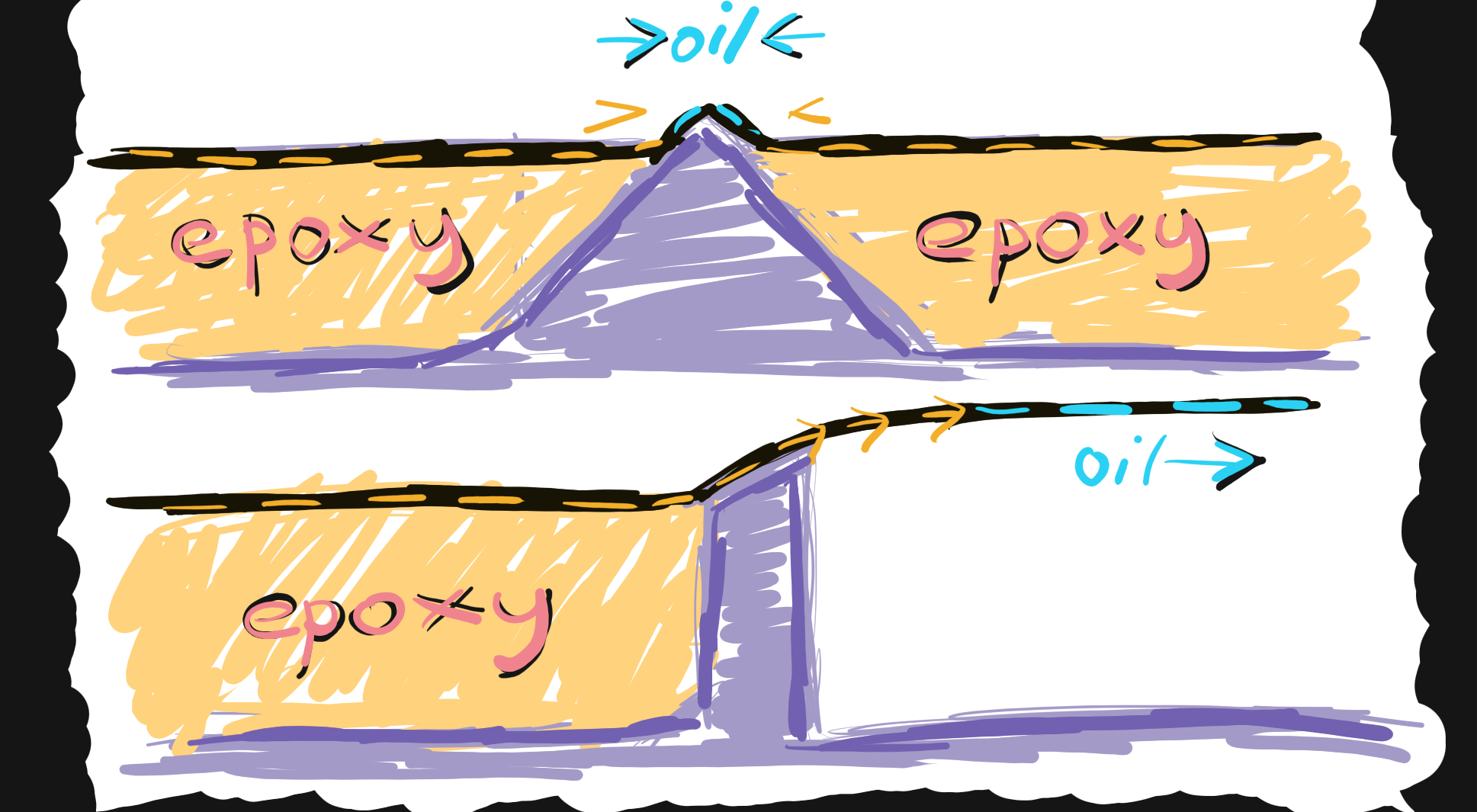

What's wrong? As soon as I realized, that not much oil is not the case, I've imagined this picture: - On top you can see previous structure. Oil stays in place, because it is pushed by epoxy from two sides

- On top you can see previous structure. Oil stays in place, because it is pushed by epoxy from two sides

- Bottom is a new version, there is big air gap. And come on! Epoxy pushes oil somewhere!

How queer! But looks reasonable after all

Now main target is to find a way how to prevent it, because new structure looks promising and bends not so bad even with this major flaw in design. I made a wonderful GIMPed picture of that:

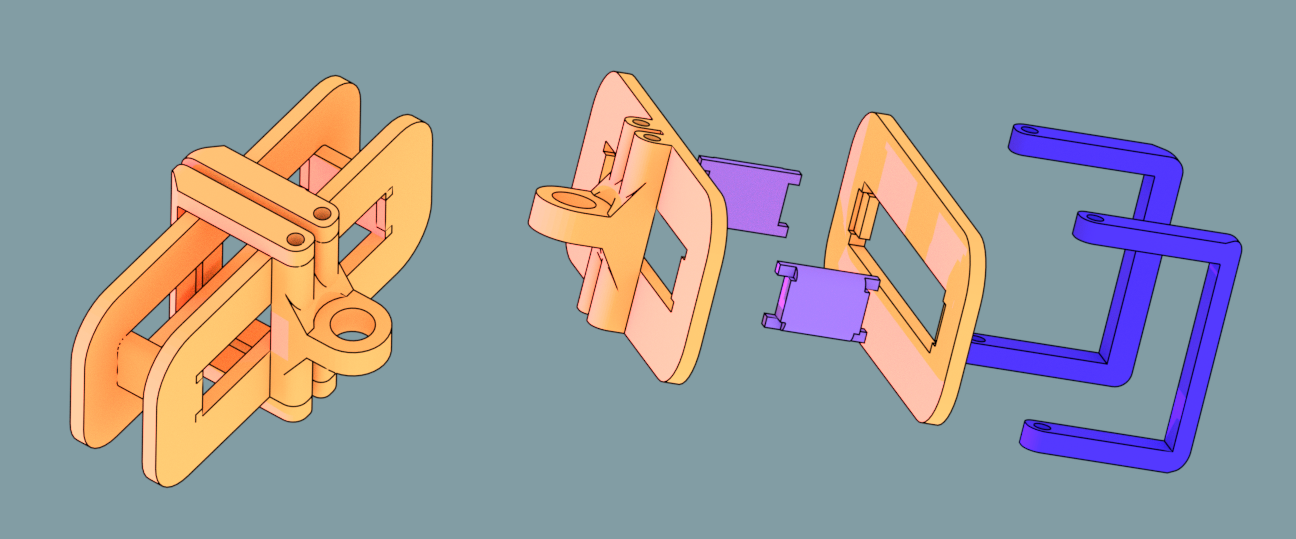

Also I found a core for electromagnet, and designed a coilformer for test purposes:

Looks similar to the preview version, now it is sectional to be easily printable. Eager to complete electromagnets part! This is the last step before first test of an actuator. Except mold-fixing, haha

Looks similar to the preview version, now it is sectional to be easily printable. Eager to complete electromagnets part! This is the last step before first test of an actuator. Except mold-fixing, haha CapitanVeshdoki

CapitanVeshdoki

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.