Yesterday I told, that I haven't found an another way how to improve electromagnets,

It was partly true - I found one way, but I thought that it was impossible due to some reasons. Then I realized, that I might know a solution! And it seems possible to me now.

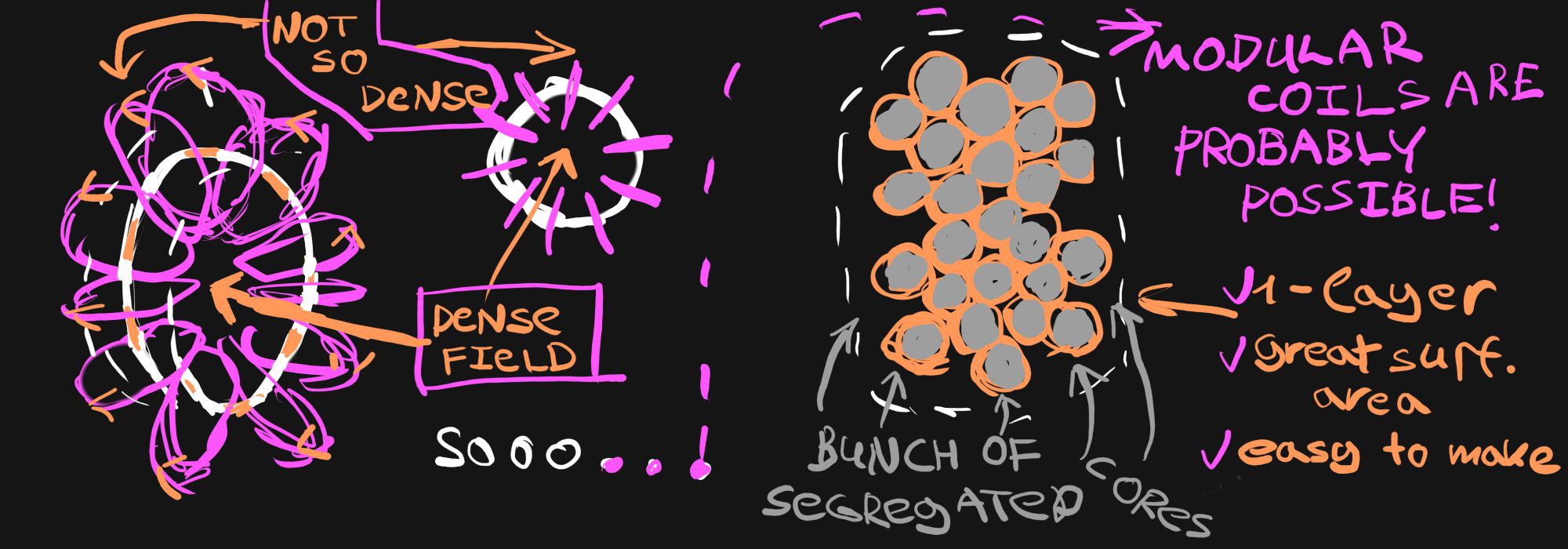

In previous logs was the idea - closer you place wire to a core, more efficiently it use current to induce magnetic field into core. So how we can maximize surface area of a core to place as much coil on the first layer as we can?

Solution for that was something similar to radiators which dissipate heat. However there was one problem - on the different sides of wire you have field with opposite direction, it weakens nearby electromagnets.

And today epic idea came to my head - it's right for straight wires, but around curved ones much more dense field is on the internal side of a curve, while outside it's kind of a weaker field!

I tried to show it on the left side, you can see one turn of a coil there. Seems logical!

I tried to show it on the left side, you can see one turn of a coil there. Seems logical!And what are our benefits?

- we achieve amazingly big surface area here!

- with help of this surface area we can use only first layer around each coil

- it delivers amazingly strong field inside of a coil

- so magnet becomes more powerful

- we can construct cores of different shapes using similar elements!

- coils are placed INSIDE of a core, so it makes electromagnet more compact

Oh. And pretty sorry - I made a mistake in previous logs, thinking, that more current is more important then number of turns. They are equally important!

But diameter of wire affects resistance significantly, so by reducing wire diameter two times, we increase number of turns only twice, while resistance increases 4 times.

That's why I had an idea, that current is more important.

So now, before arrival of induction heater I can check this theory also.

It has some sort of Sci-Fi look with all those honeycomb shapes! huhuhu

CapitanVeshdoki

CapitanVeshdoki

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

The only thing that counts is the overall current going through the coil cross section. There is not really anything to gain by using thicker or thinner wire. All it does is changing the voltage required at the ends. Think of it as a magnetic transmission translating between needed voltage and current. In the end you can put the same overall current through the same area of copper creating the same magnetic field. It's a zero sum game.

Are you sure? yes | no

> The only thing that counts is the overall current going through the coil cross section

Wow, never thought about coils from that perspective! Everything seems clearer now.

I thought about that for a while, it seems, that distribution of a cooper area means a lot also. And the most reasonable distribution - thin wire, one layer. However, it requires great voltage to operate - there is no way to remain same area with one layer and finite length of core. Modular design can help a little with that. So it is also a compromise between size, voltage, efficiency and strength of field, as I see it now. (under efficiency I mean which part of field, produced by a current, is used for core magnetization)

Update: Uuh, It's a pleasure to understand something more physically, not on language of formulas! Yes, everything is in place now. Big thanks for that! : )

I would try to check modular conception on Monday. I've made 18 cores (although, material still isn't the best), next quest is to decide which diameter of wire I want to use there respectful to current configuration of control circuit.

Are you sure? yes | no