The Laser Dye Project merges alternative photography with digital fabrication by producing New Cyanotype and Vandyke Brown on sewn garments made from natural fibers or delicate, uneven organic substrates. Using maskless laser exposure with a DIY programmable laser galvanometer system, the process translates light directly onto fabric without the need for physical masks. This approach not only allows large-scale exposures but also enables multi-angle printing with several laser machines.

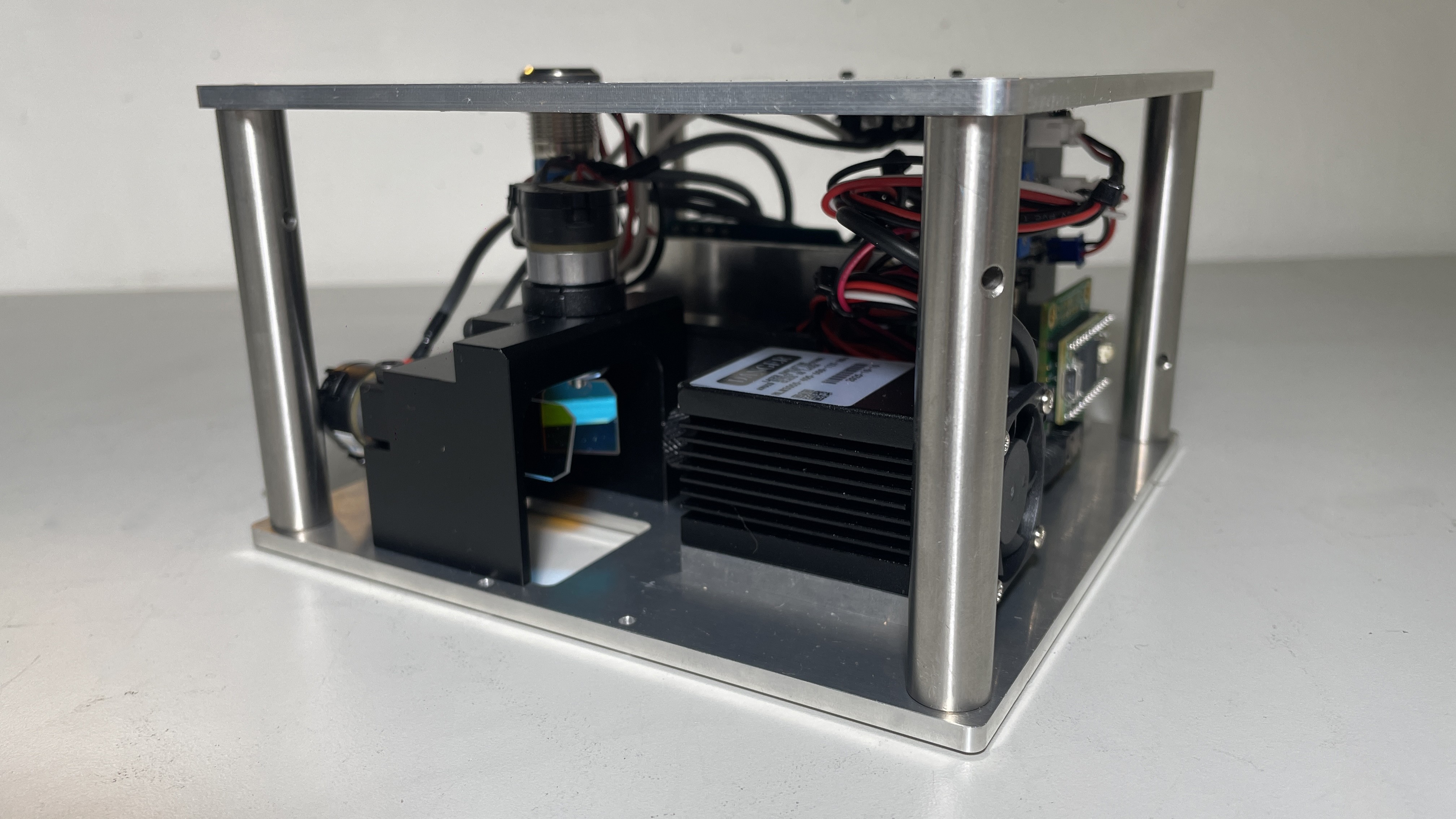

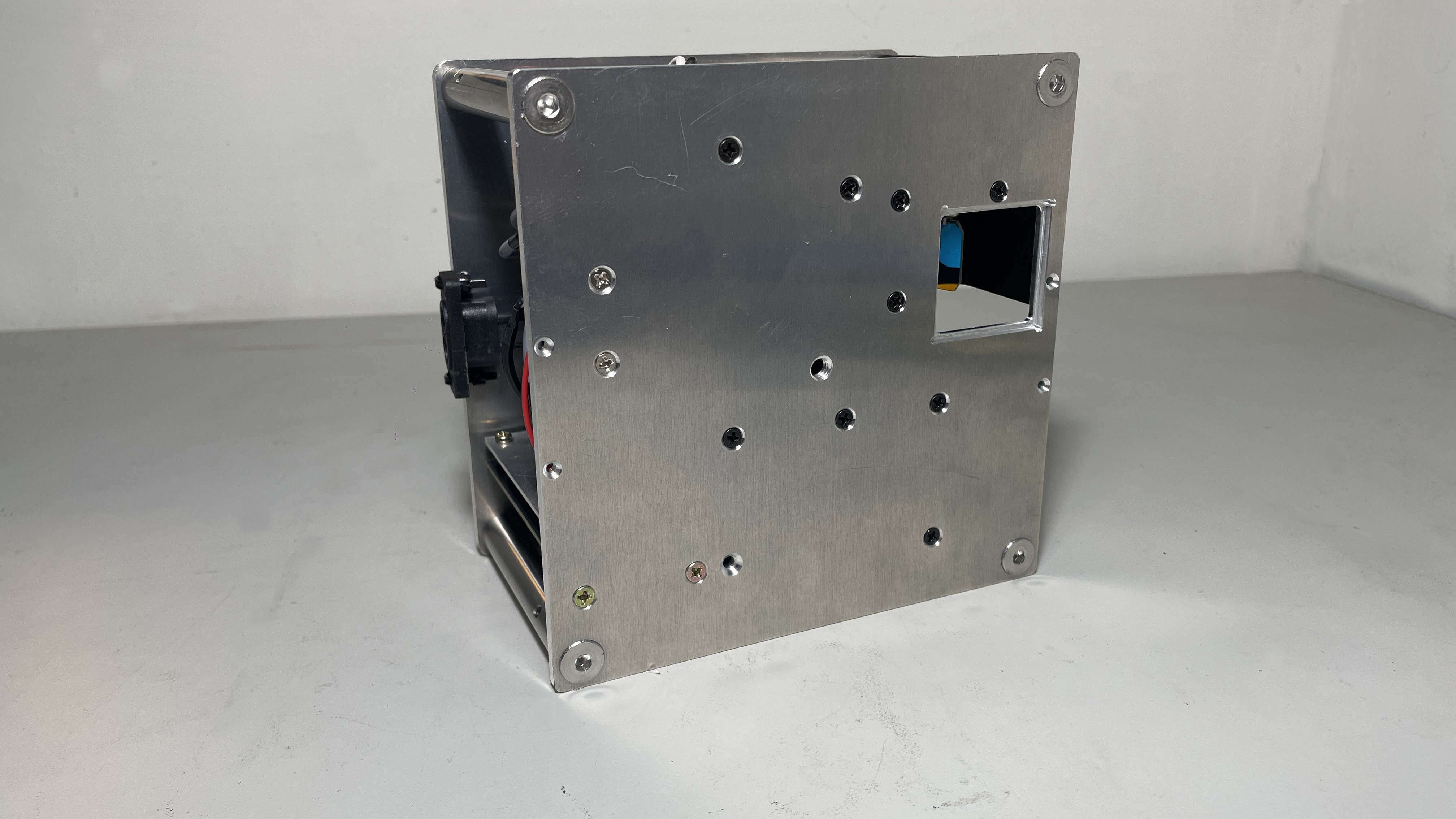

1. Programmable Galvanometer laser scanner

The galvanometers module PT-A40 using in this project can be purchased from GT-TECH. The laser source is a 405nm, 600 mW module. You can also go for RGB source with two more extra audio signal inputs.

For the laser signal control, conventional ILDA interface is ignored here, all the signal is synthesized in Max/MSP and sent from the MOTU sound card to the DIY laser machine with audio cables and a adaptor board. MOTU is a powerful sound card outputs DC coupled outputs which is important for the printing, engraving or other laser show application. I made a cable to connect MOTU and regular laser machine by following the design here.

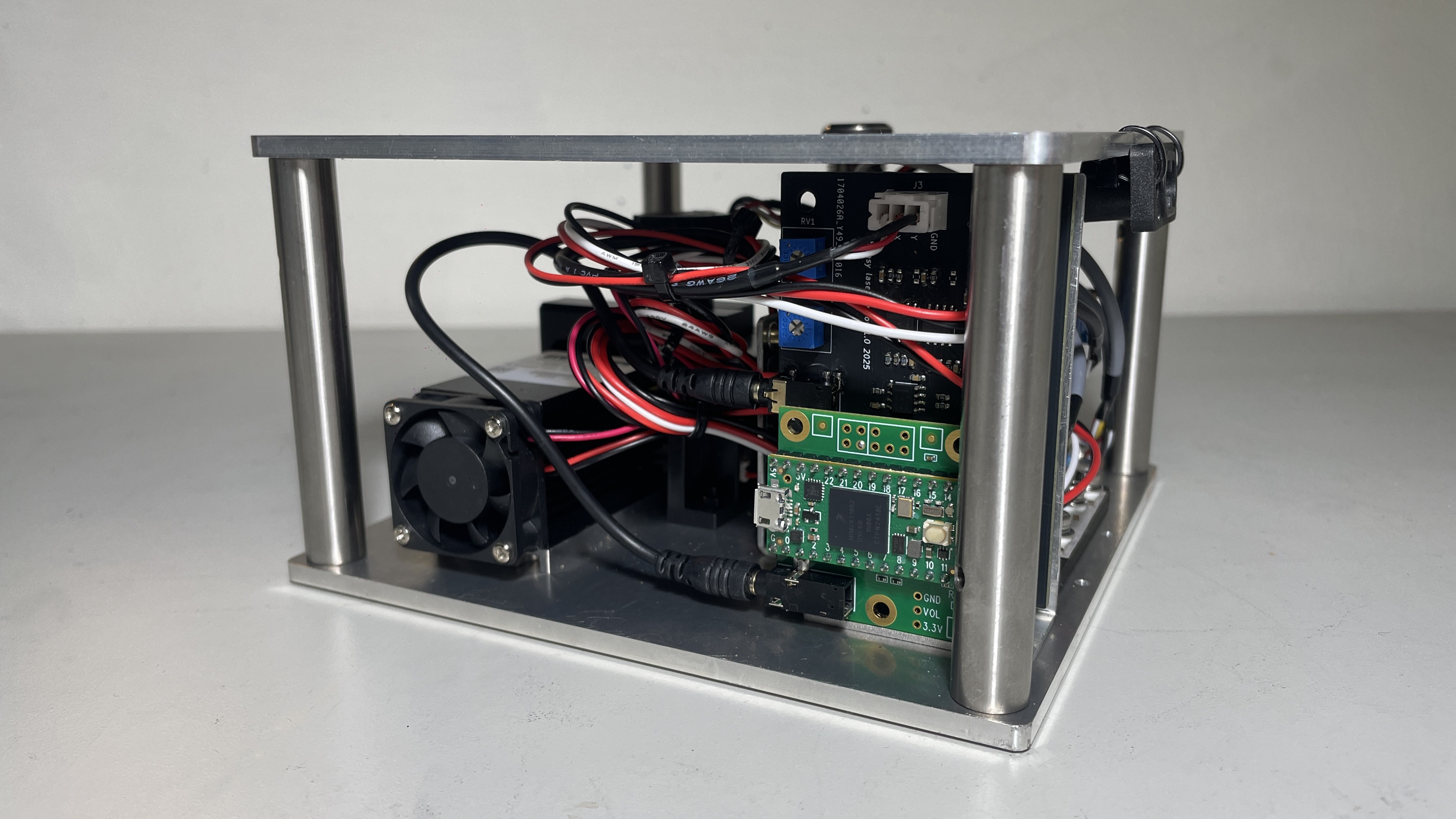

2. The Teensy and the laser signal adaptor board

However, due to the price of the MOTU device is around 800$, I have tried many options to replace MOTU, like daisy board, axolotl and Teensy, but all of these only have acess to the x and y control. Eventually I use Teensy + Teensy audio adaptor board as my final solution. The Kicad file of the adaptor board can be found in the Github.

3. Laser graphic synthesis in Max/msp

The control interface is made with Max/MSP. I wrote few patches to convert photo to galvo movement. The Max/MSP patches can be found in Github too.

4. New Cyanotype not cyanotype

I reference New Cyanotype process of Mike Ware to develop the cyanotype on natural textile masklessly. New Cyanotype is much more sensitive therefore the developing time is much shorter, this is critical for making large work or garment. I alter the water portion of the final working solution of New Cyanotype. The more water in the working solution the faster the image develops, but you yield the color quality and saturation a bit.

Note that New cyanotype can only be applied on natural textile like cotton, linen, silk, important to acidic the textile before and after laser exposure. Make up a stock solution of citric acid to 40% w/v, and add one drop (0.05 cc) to every cc of working solution you made. (for example if you make 100 ml of working solution, drop 100 drops of citric acid water in it).

- Firstly soak the fabric in boiled water to remove the chemical, stains on it.

- Soak the fabric in light acid water for 10 minutes, then rinse it with distilled water and let it dry.

- Prepare. 100 cc of stock sensitizer solution

- Add up 5 cc of 40% citric acid solution in the sensitizer.

- Fold the fabric into small square and soak it into the sensitizer directly, pressure it to make sure it's dyed properly without empty blank left. Extract the extra solution out to make the fabric as dry as possible.

- Leave it completely flat on floor or table (no wrinkles are allowed) and dry for 30 minutes in completely dark space.

- Laser exposure it after it's completely dried.

Shih Wei Chieh

Shih Wei Chieh

Jonathan

Jonathan

LesWright

LesWright

Steve Schuler

Steve Schuler

FabLab München

FabLab München

So beutiful and clever work!

Now - make something in 3d... Not on 3d objects but light activated medium must give volumetric effect...

I will share my idea soon!