It turns out that the threaded inserts that I purchased for securing the LX-16A - Coupler to the drive shaft did not work very well. I suspect, because of the direction of the groves.

To fix this, I decided to change the design of the LX-16A - Coupler and several other parts that used the inserts. I am very happy with my new design and find that I can really tighten the setscrew, as well as it being cheaper.

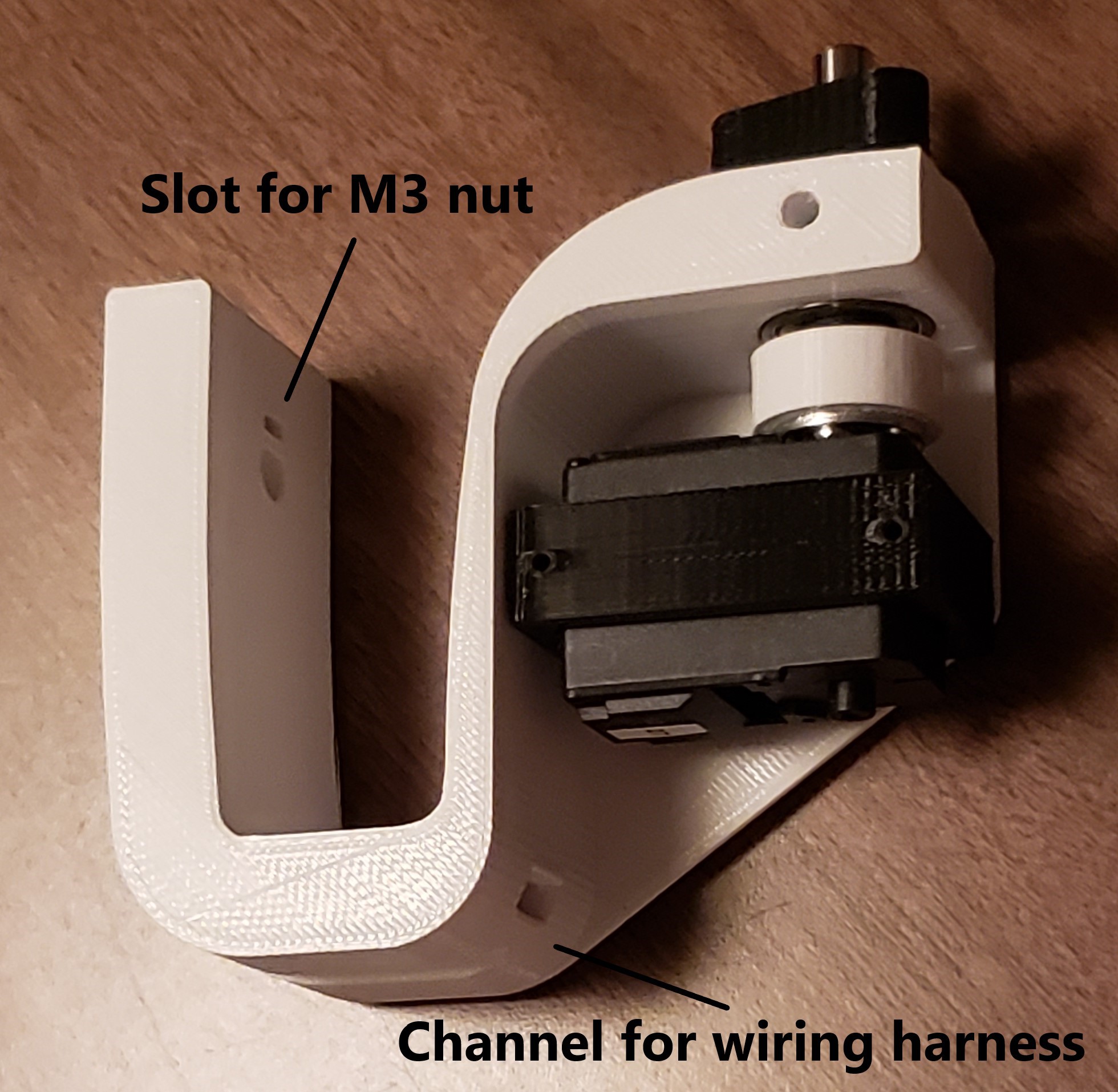

Basically the new design puts a slot in the part that will hold an M3 nut. I also keyed the hole so that the part is tight on the shaft, reducing the work of the setscrew. This new design is working very well.

I made the same changes to the steering knuckles.

At the same time, I created a channel to hold the wiring harness, just to clean things up visually.

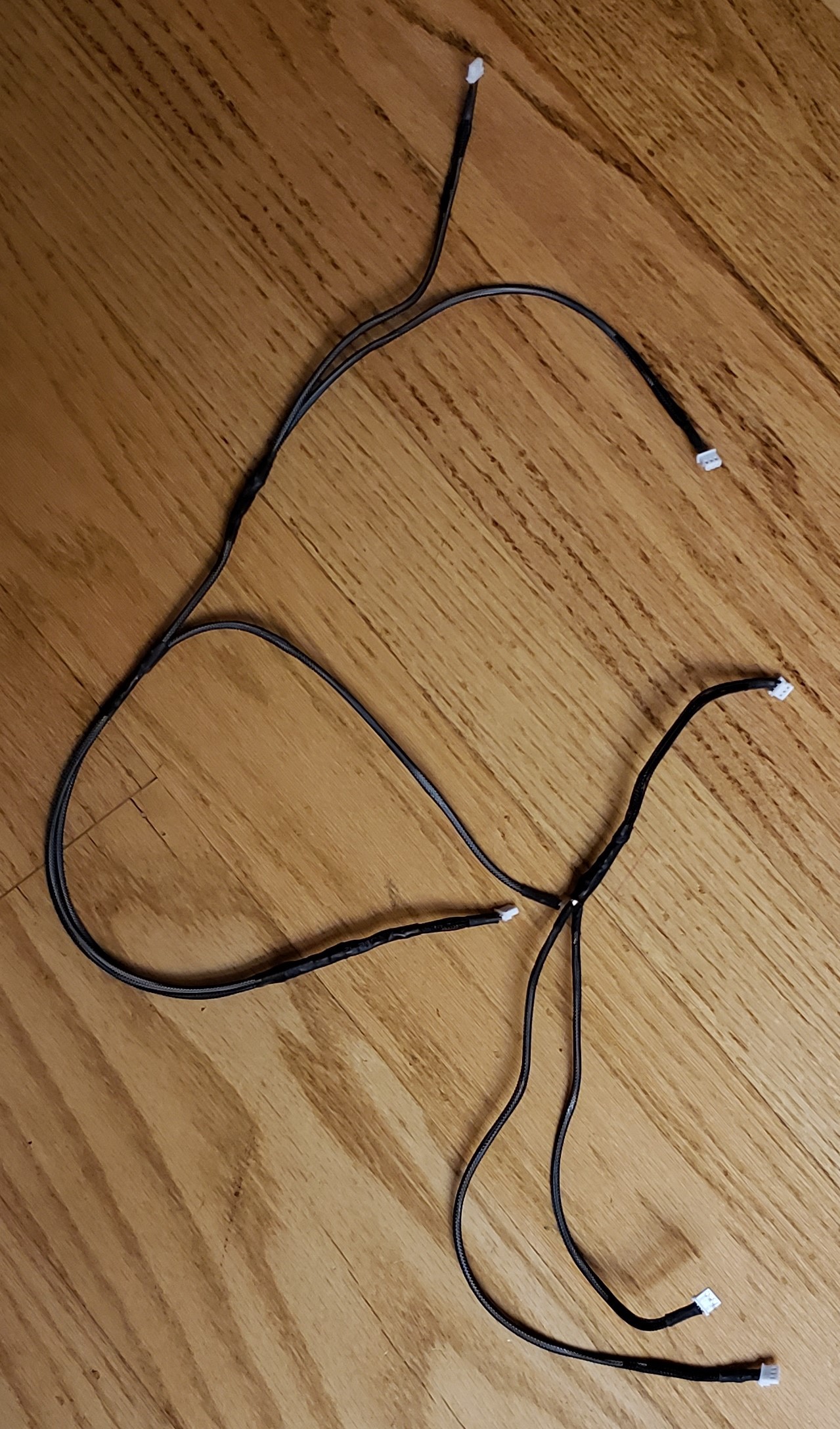

This is a picture of my wiring harness. I spent a lot of time putting this together, and am very proud of it. I used Techflex 1/8 Inch PET Expandable Braided Sleeving and shrink tubing to keep the wires neat.

lmckeega

lmckeega

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.