Overview Video:

Step 1: Design

As I mentioned before the shape is made from 3mm acrylic, made by a laser cutter accurately.

And the design is inspired by some open source designs available online.

Arm length: 60 cm

Width: 10 cm

Height: 45 cm

Wight: 900 gm

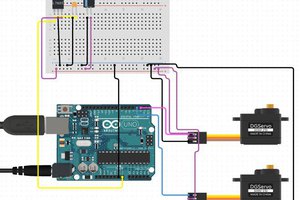

Step 2: Electronics Component

- Arduino board

- Arduino sensor shield

- Step down module (optional)

- X3 servo motors MG955

- X2 micro servos 9G

Step 3: Building the Shape

The Design has five degrees of freedom and it means we need 5 motors to achieve the target.

And degrees of freedom (DOF) means:

In statistics, the number of degrees of freedom is the number of values in the final calculation of a statistic that are free to vary. The number of independent ways by which a dynamic system can move, without violating any constraint imposed on it, is called a number of degrees of freedom.

The robot arm was assembled by using some screws and nuts

First, we need to fix the base as shown.

Second, we need to assemble the claw.

The claw is powered by metal gear servo motor rotate in 180 degrees connected with two arms operated through gear.

The rest of the arm doesn’t have motors because the shoulder and elbow motors are installed in the base itself as shown, both motors mechanisms work to handle the moves

Third, The Shoulder motor moves the arm up and down

The Elbow motor moves the arm forward and backward

Step 4: Power and Battery

The whole arm is working by a 5v battery, and here I’m using four 1.2 AA Lithium batteries to power up the motors and the Arduino board itself is powered by USB cable directly to the laptop.

In case you want to use a higher battery, you need to fix

Step down module to reduce the voltage using the screw

This is an LM2596 DC-DC buck converter step-down power module with a high-precision potentiometer, capable of driving a load up to 3A with high efficiency, which can work with Arduino UNO, other mainboards and basic modules.

In general, the performance of LM2596 Step-down Power Module is very good. You had better set the output voltage 5v lower than the input voltage, then the testing results will be more stable.

Step 5: Claw Modification

Recently I had to support the claw by fixing these circular handles to facilitate the capture process.

Step 6: Programming

The Idea is to record the coordinates of each motor then play back the moves in a sequence and here how to control any servo motors using a USB mouse:

the code is separated into two application, at first, you need to install processing 3 Application and copy the code from the attached files.

Ahmed Azouz

Ahmed Azouz

Luke J. Barker

Luke J. Barker

hIOTron

hIOTron

MrDreamBot

MrDreamBot

Mike Rigsby

Mike Rigsby