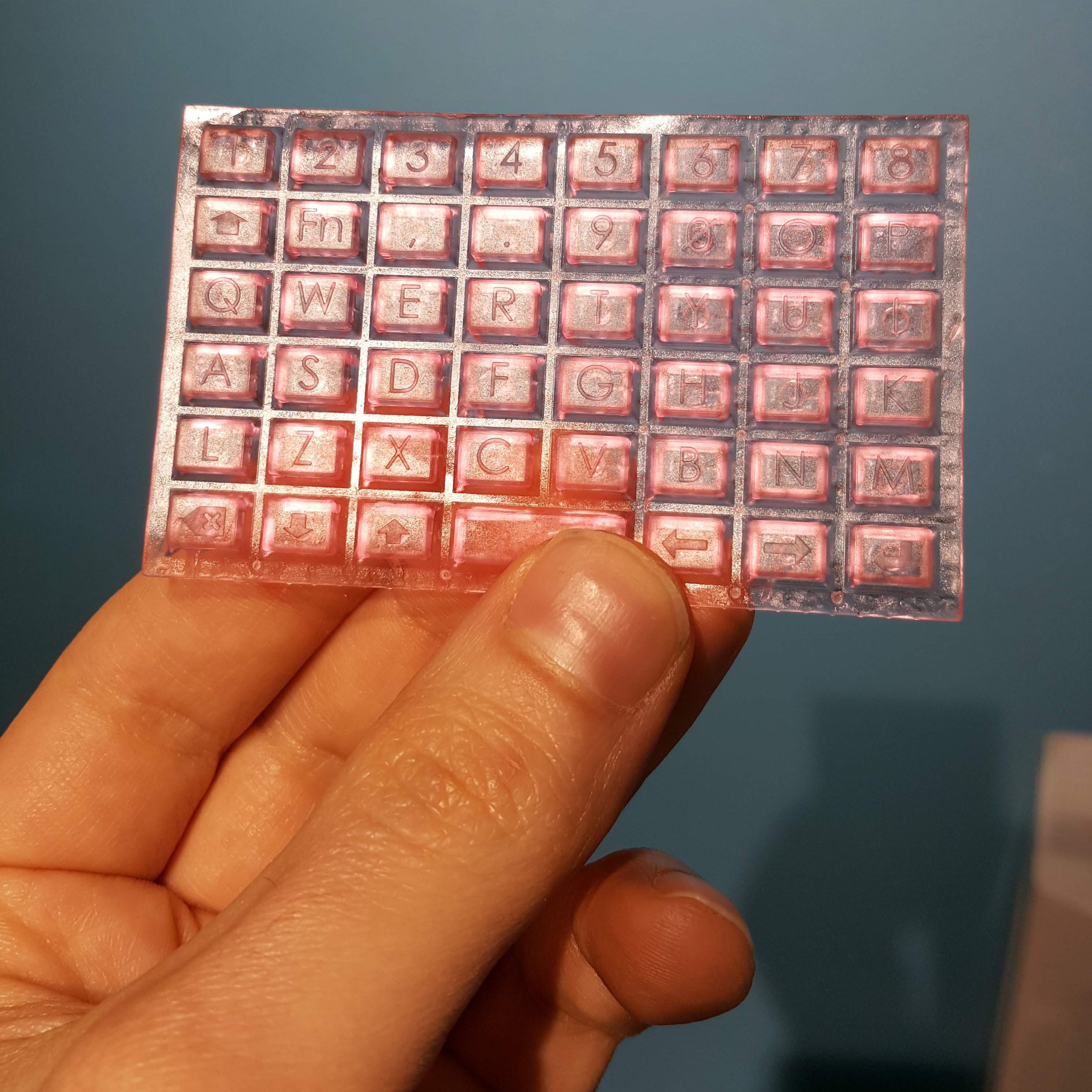

The front part is supposed to be 3D printed with flexible resin. Bare conductive ink is applied on the 3d printed "pill" that will be touching the PCB. A flexible PCB would allow a bendable, rollable keyboard.

DIY Flexible keyboard without using silicone

A DIY flexible keyboard project; instead of using silicone, a SLA highly flexible resin is used.

Madaeon

Madaeon

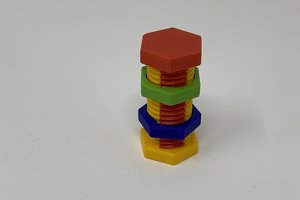

Greg Zumwalt

Greg Zumwalt

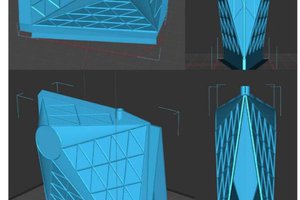

TRAN.VINH.QUANG

TRAN.VINH.QUANG

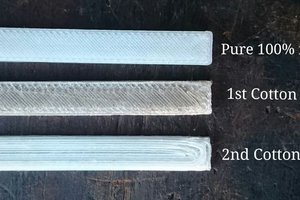

Shion

Shion

Charlie Godfrey

Charlie Godfrey

I need an xvkbd layout for my smart phone I make them out of super glue and plastic bags now and it's very messy.