The idea is quite simple: Stick some resistive wire under the build plate and tap into the 19V power supply of the Cetus to heat it up.

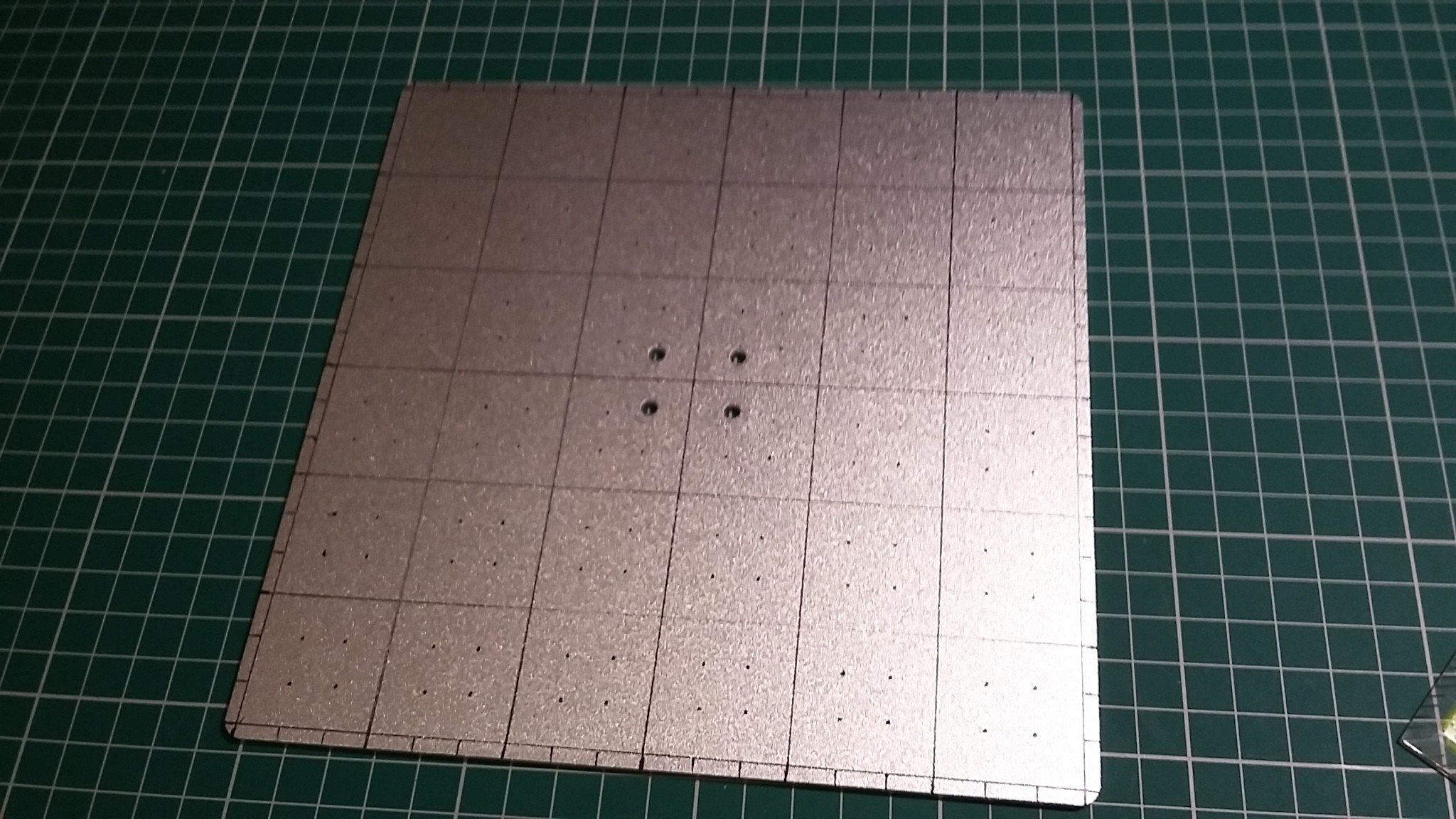

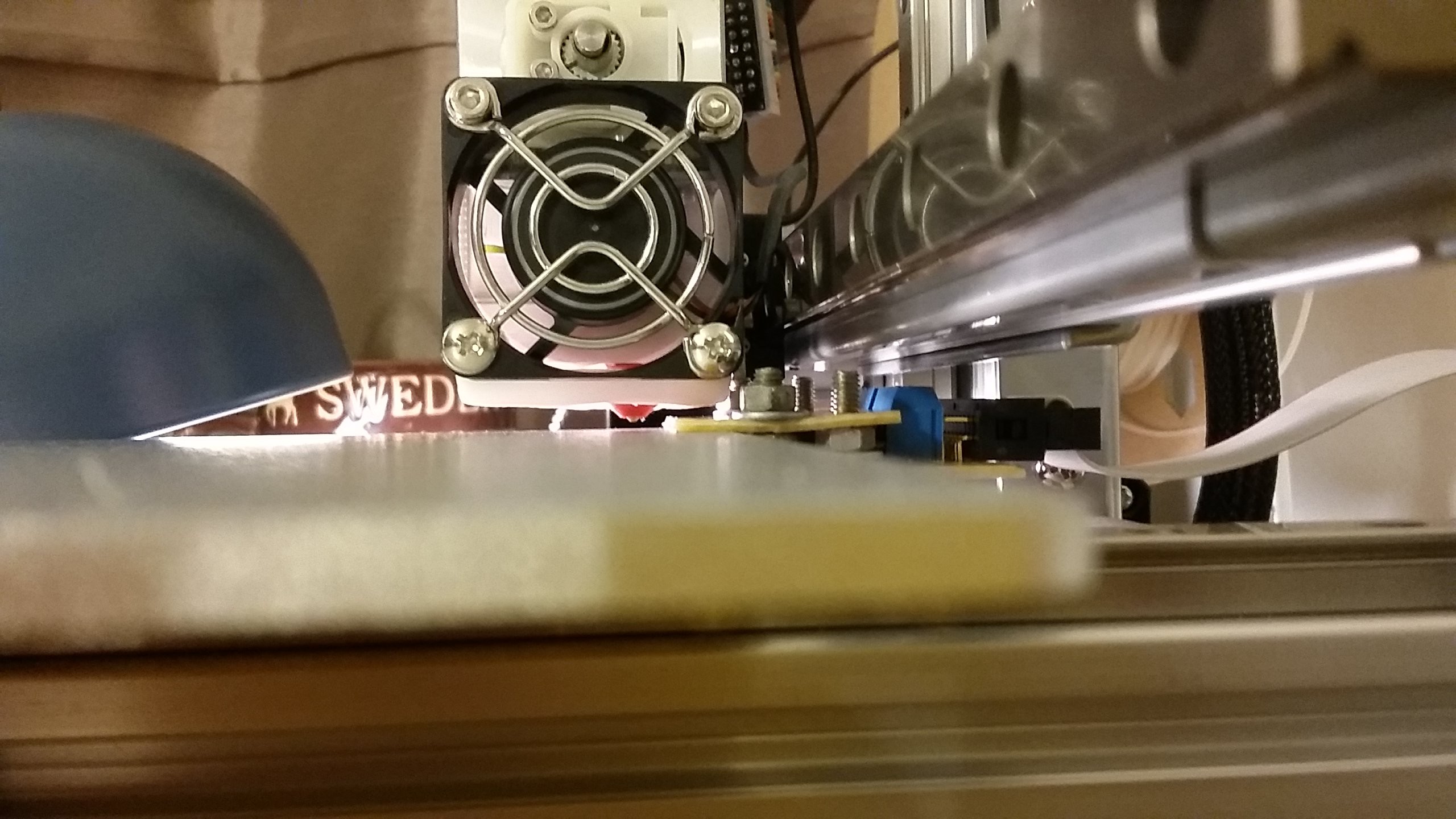

I started by drawing some guide lines on the under side of the Cetus' build plate:

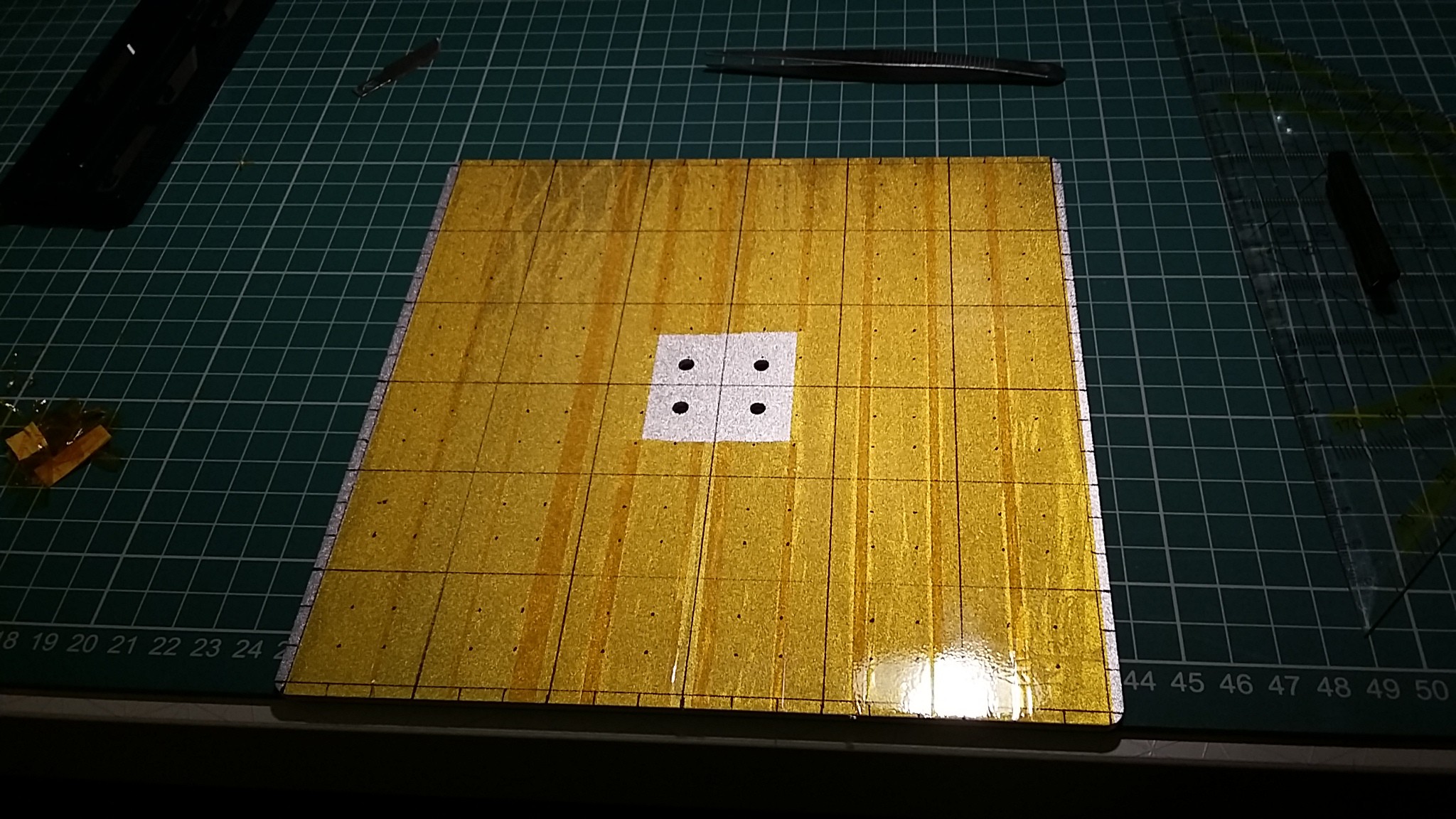

I then covered everything except the centre with kapton tape for insulation:

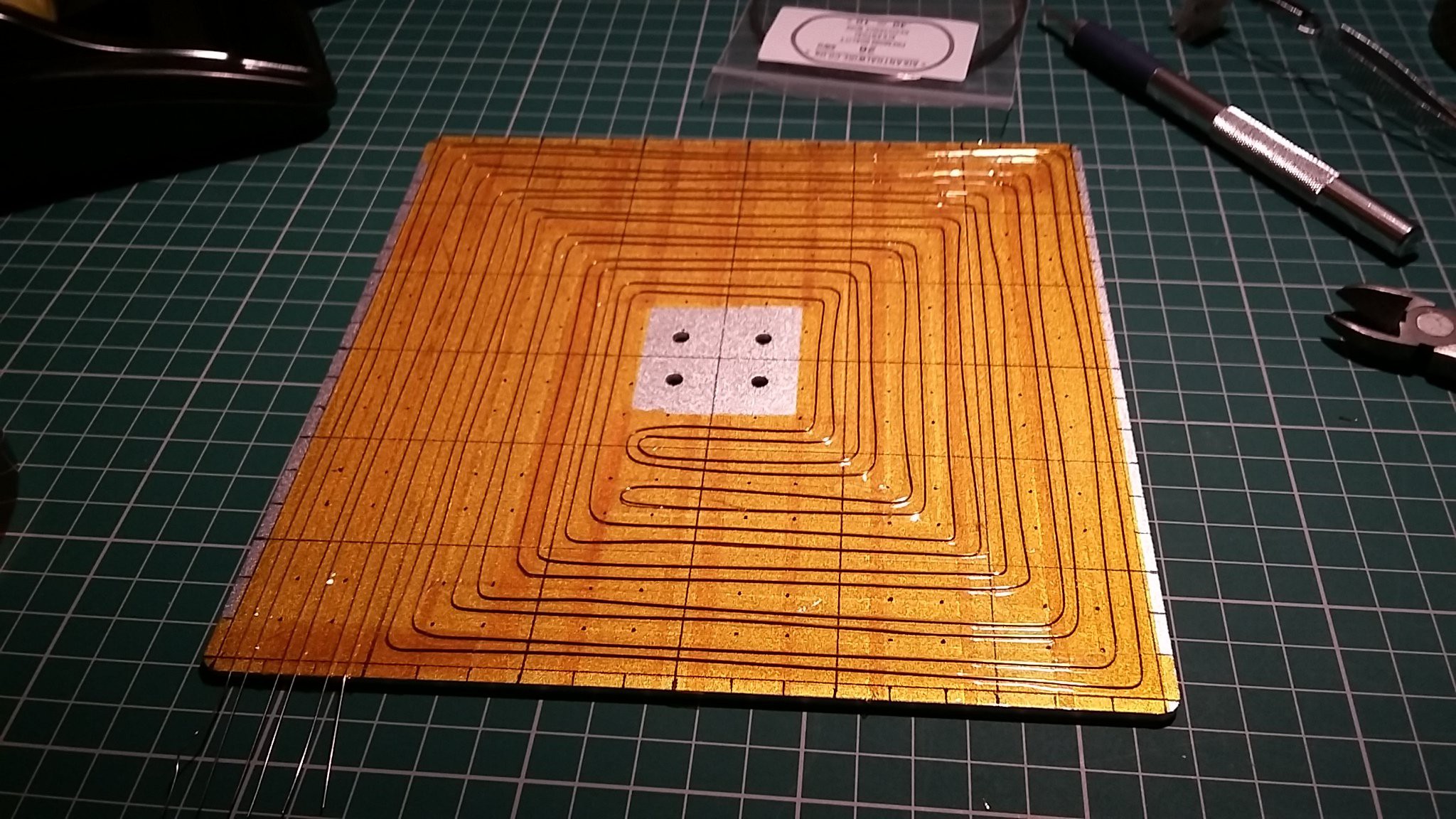

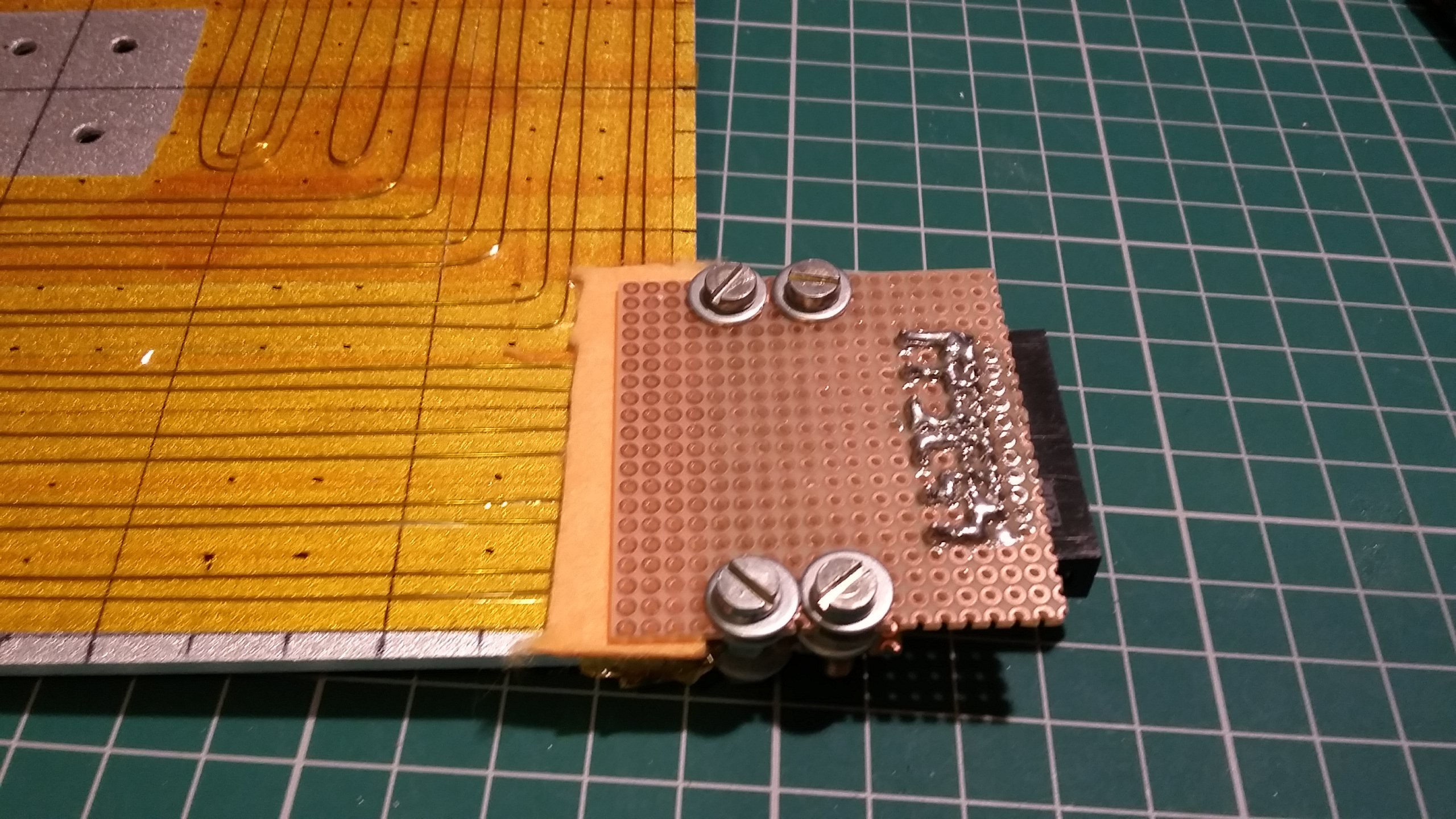

I laid out three separate loops of 26 AWG (0.40 mm) A1 kanthal wire, and covered everything with another layer of kapton tape:

Each loop has a resistance of between 25 ohm and 32 ohm.

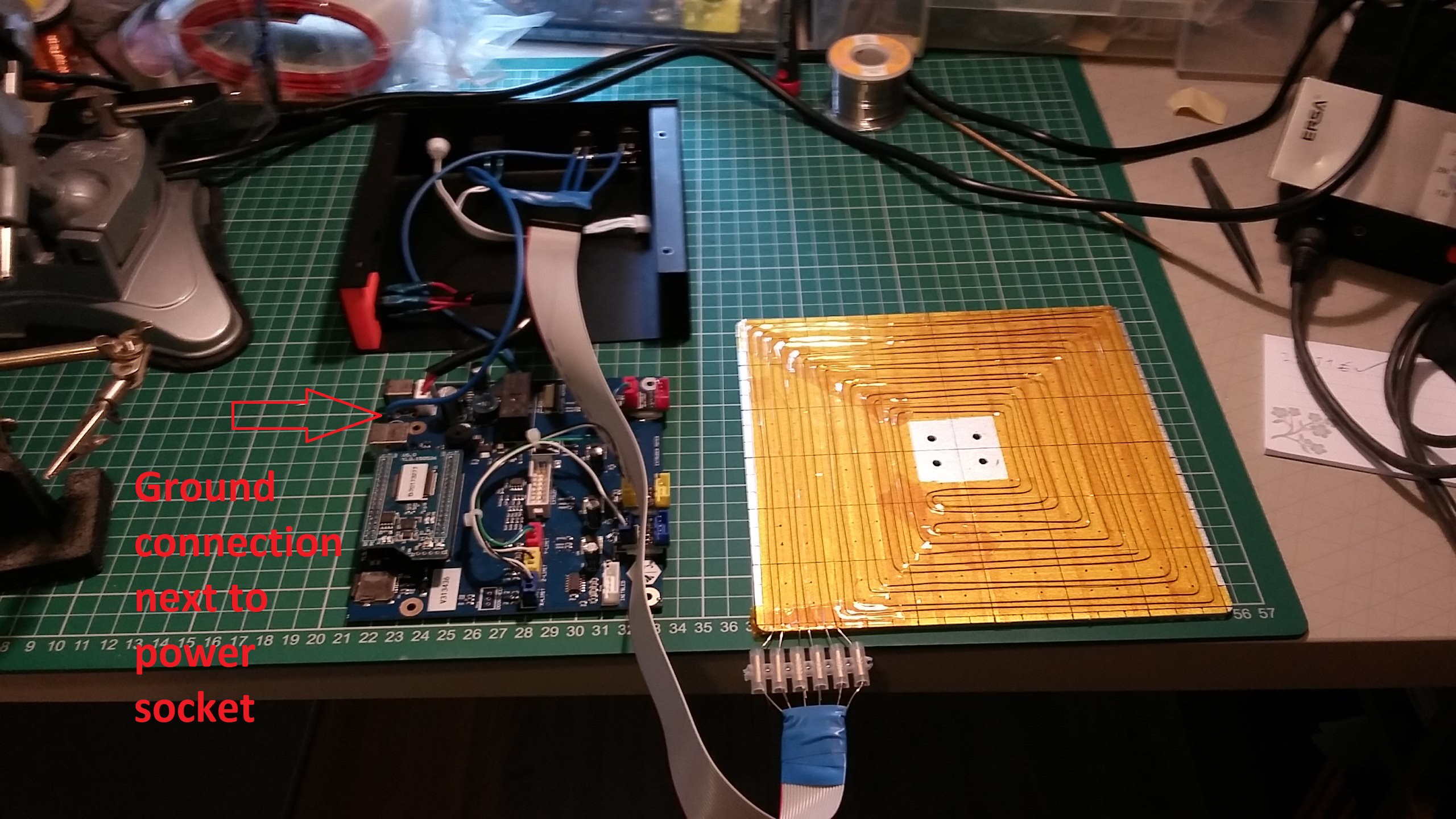

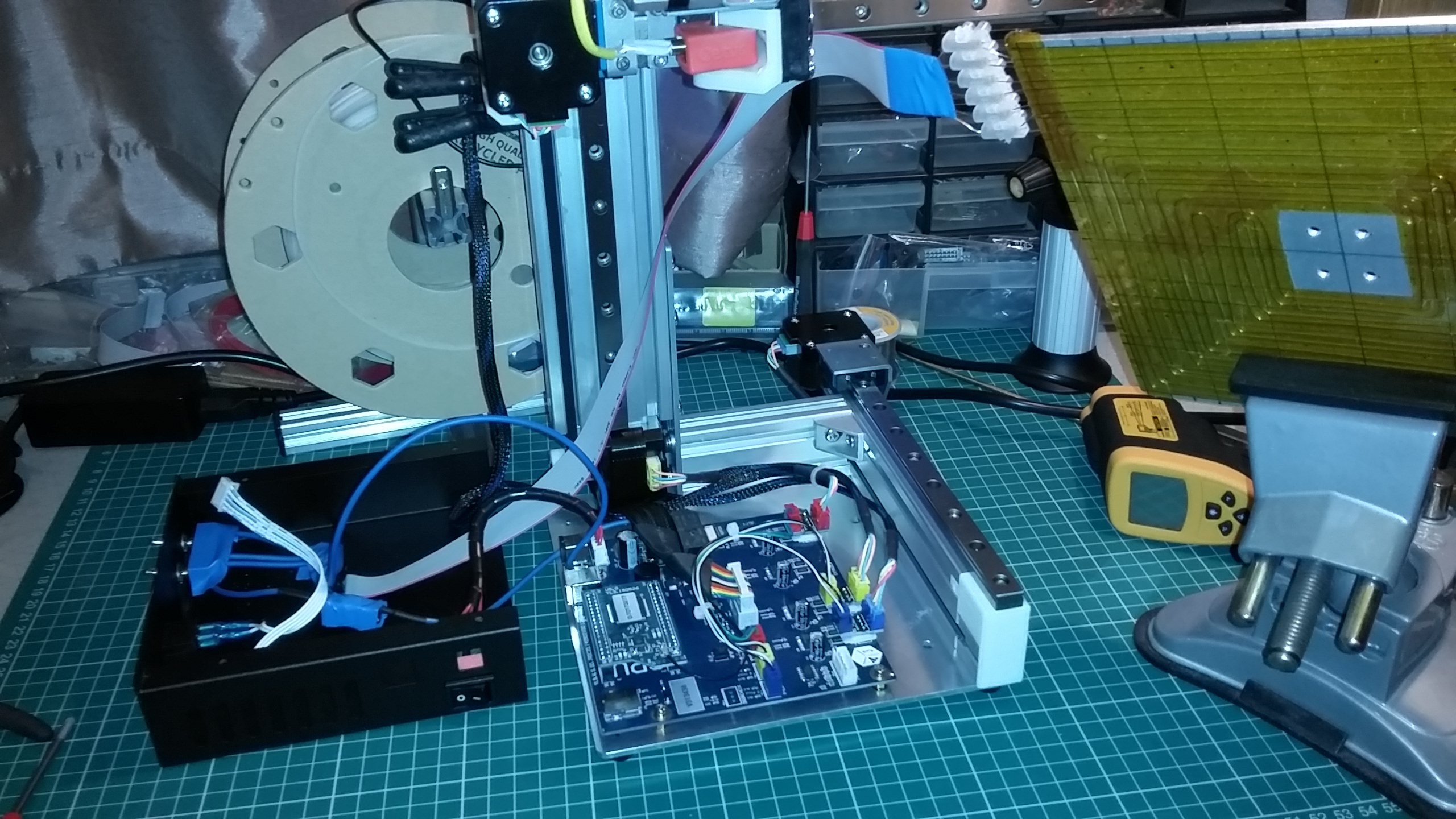

I attached some ribbon cable and connected the loops to two switches I added to the front of the Cetus' electronics case:

One switch switches two wire loops in parallel, the other switches the remaining loop. This gives me four possible power settings: 0%, 33%, 66%, and 100%. Just like the commercially available heated bed, there will be no temperature control. The final temperature will be determined by the equilibrium of heating by the wire and heat loss to the environment.

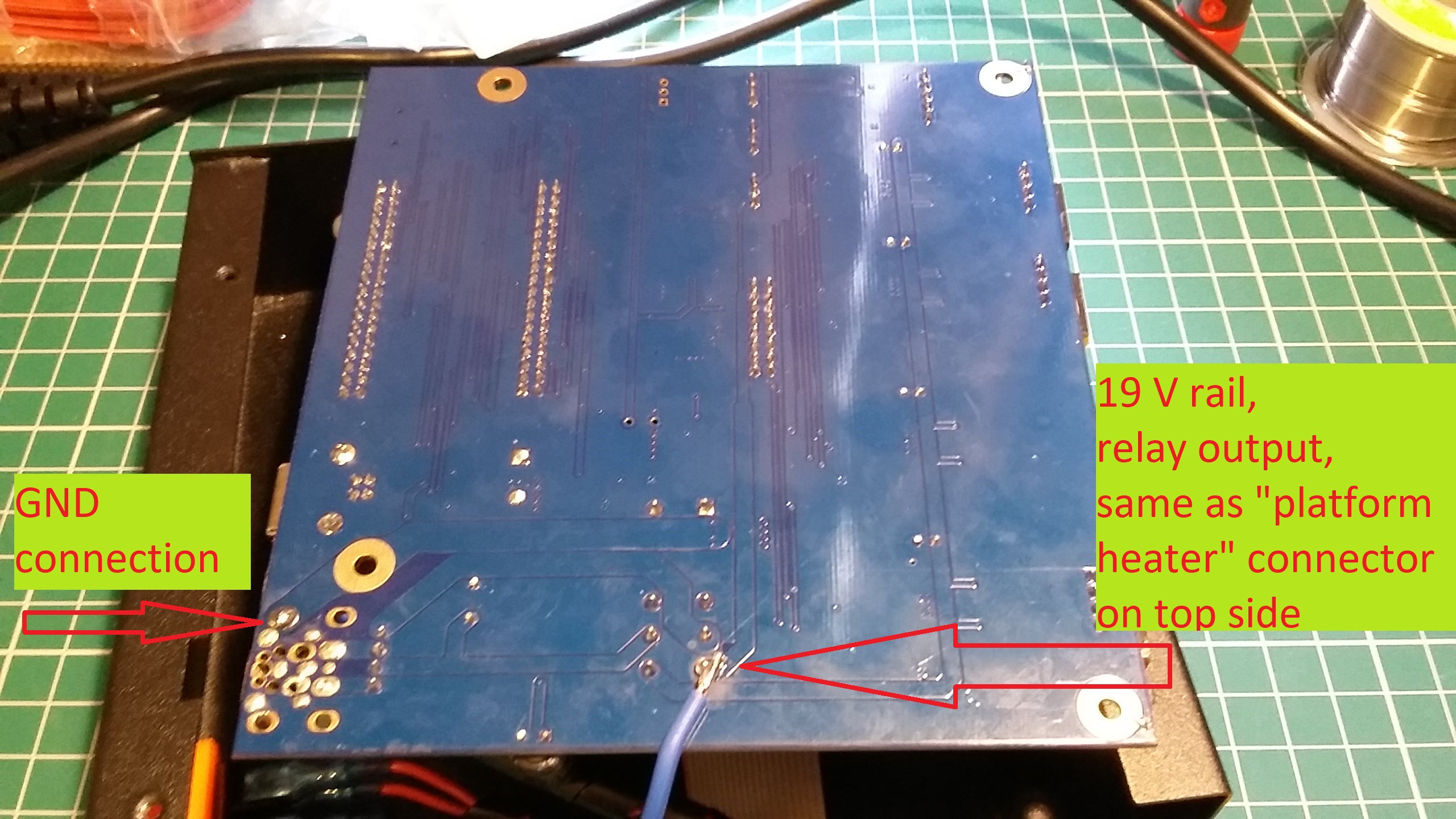

I tapped into the 19V power supply on the bottom of the main board:

First tests showed everything to be working. On 33% power (one loop active), the platform reaches a temperature of 37 degC. On 100% power (all three loops active) it reaches almost 70 degC.

At this point I decided to put a 4A fuse in the 19V line. Just to be safe.

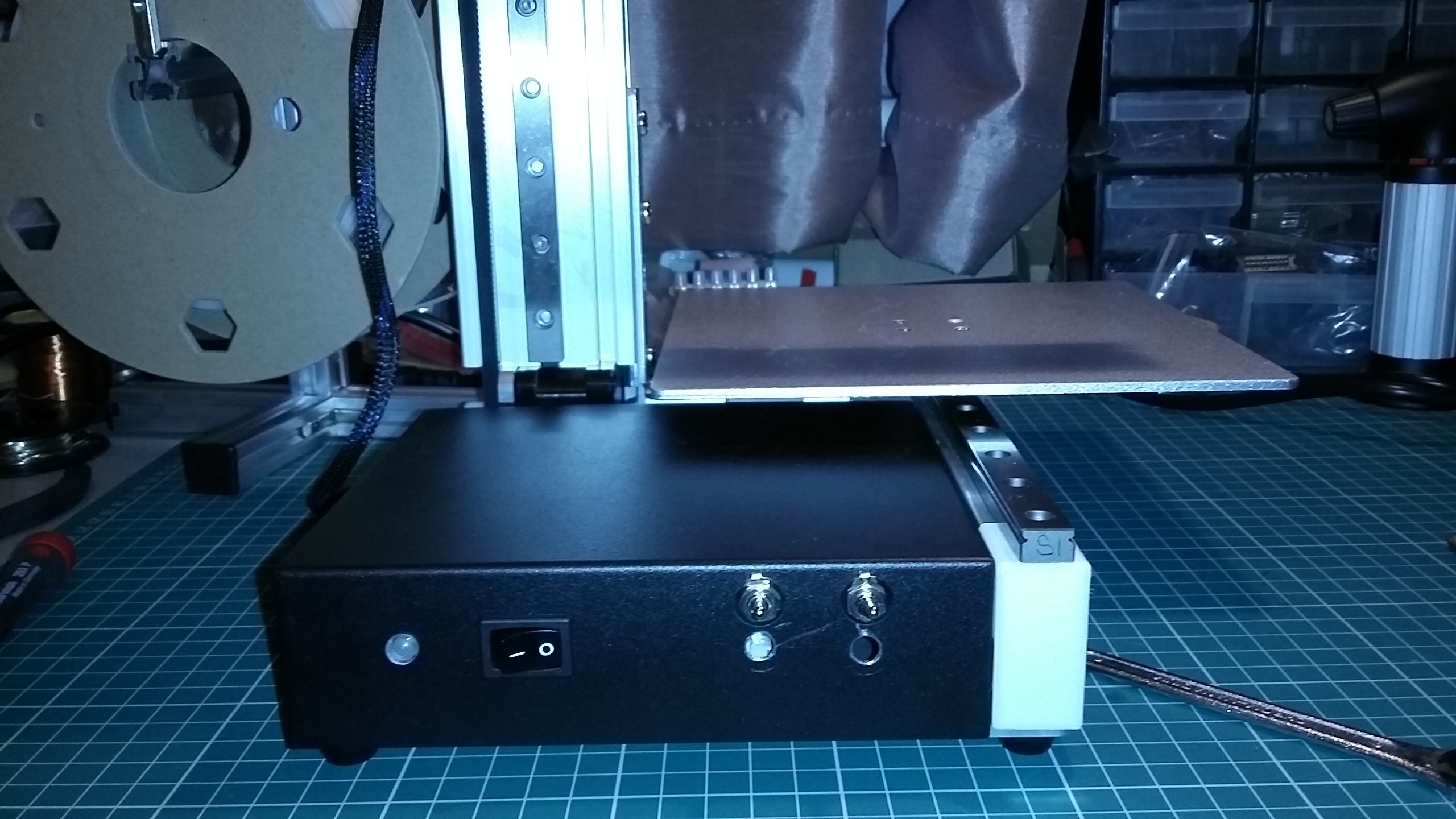

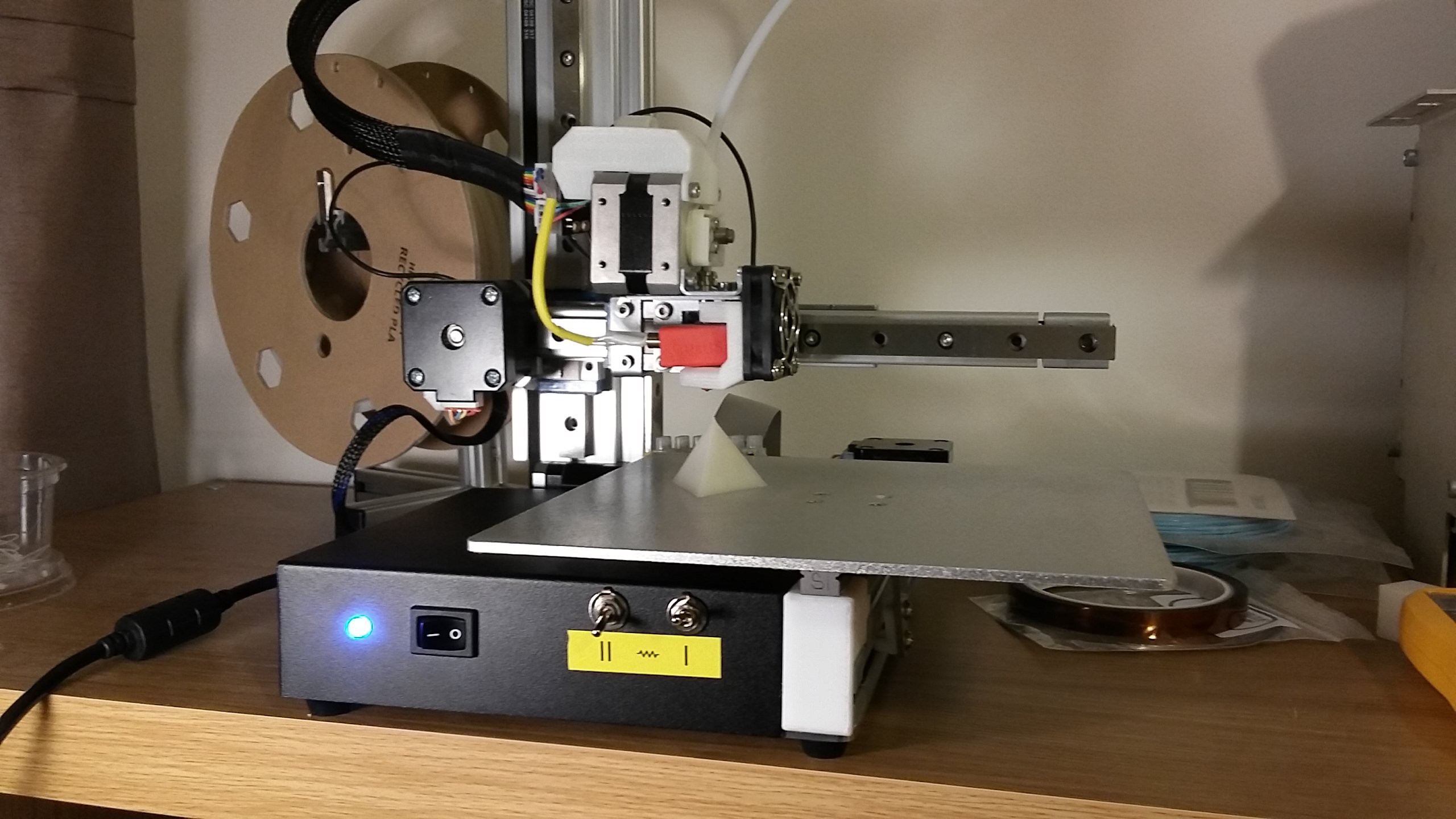

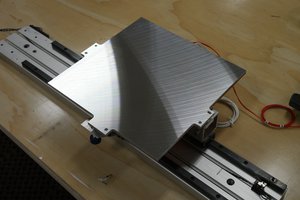

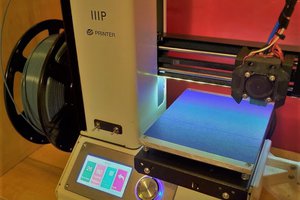

Time to re-assemble the printer:

Of course everything worked flawlessly. Why do you ask?

"Measure once, drill twice", that's how it goes, right? And who would have expected the switches to interfere with connectors on the mainboard? Anyway, this faux pas was easily fixed with the application of a label printer:

For PLA, a single wire loop is enough to heat the bed. The adhesions with the first test print was very good.

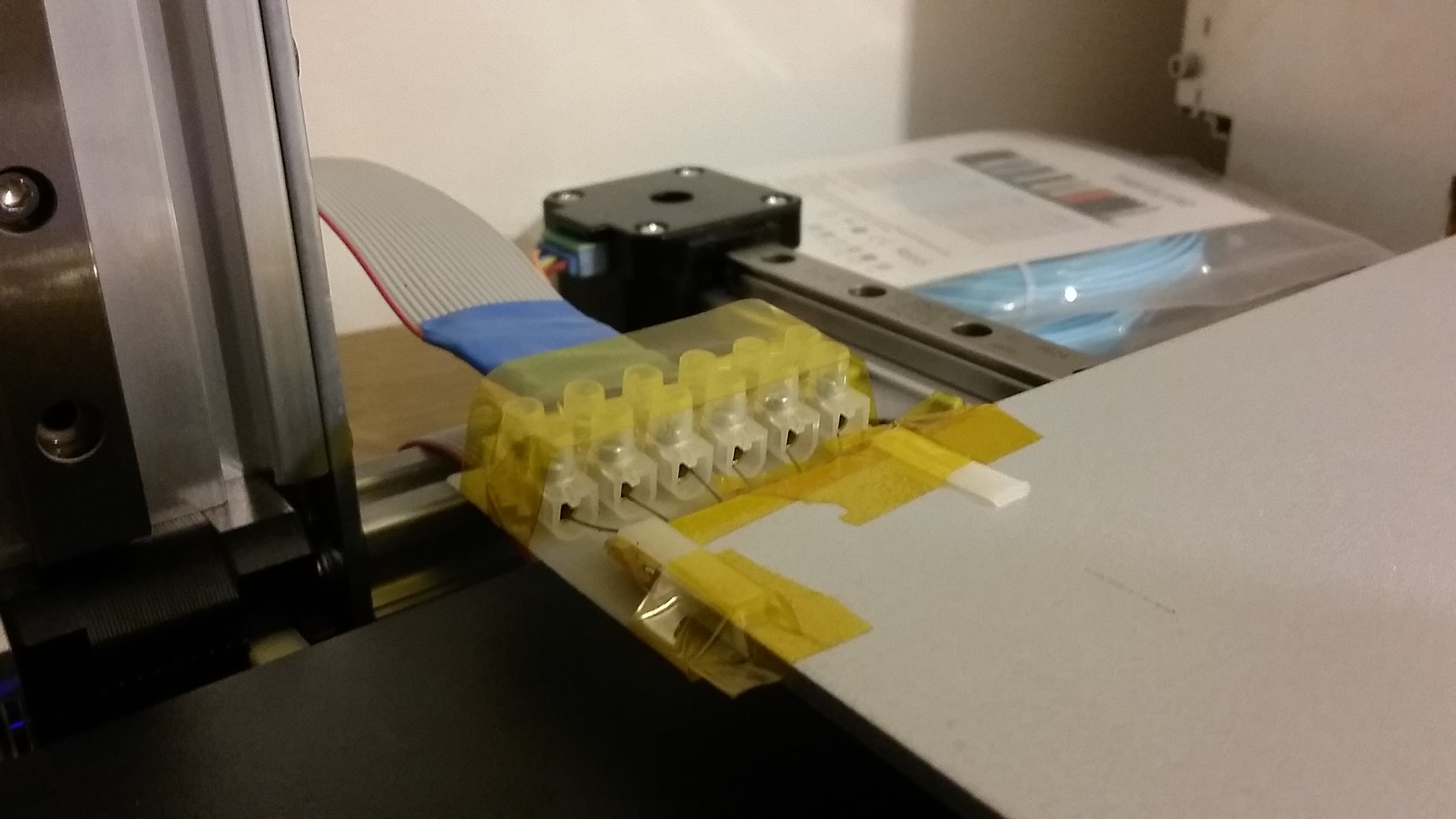

I plan to implement a proper connector and strain relief for the resistive wires on the the back of the build plate. For now, a temporary fixture should make sure that the wires don't fail:

The current connection takes up quite a bit of space. This is incompatible with my plans to put the printer in an enclosure in my shelf. Also the fixture is printed from PLA, so it would not fare well at 100% heating power. Definitely upgrade worthy.

UPDATE:

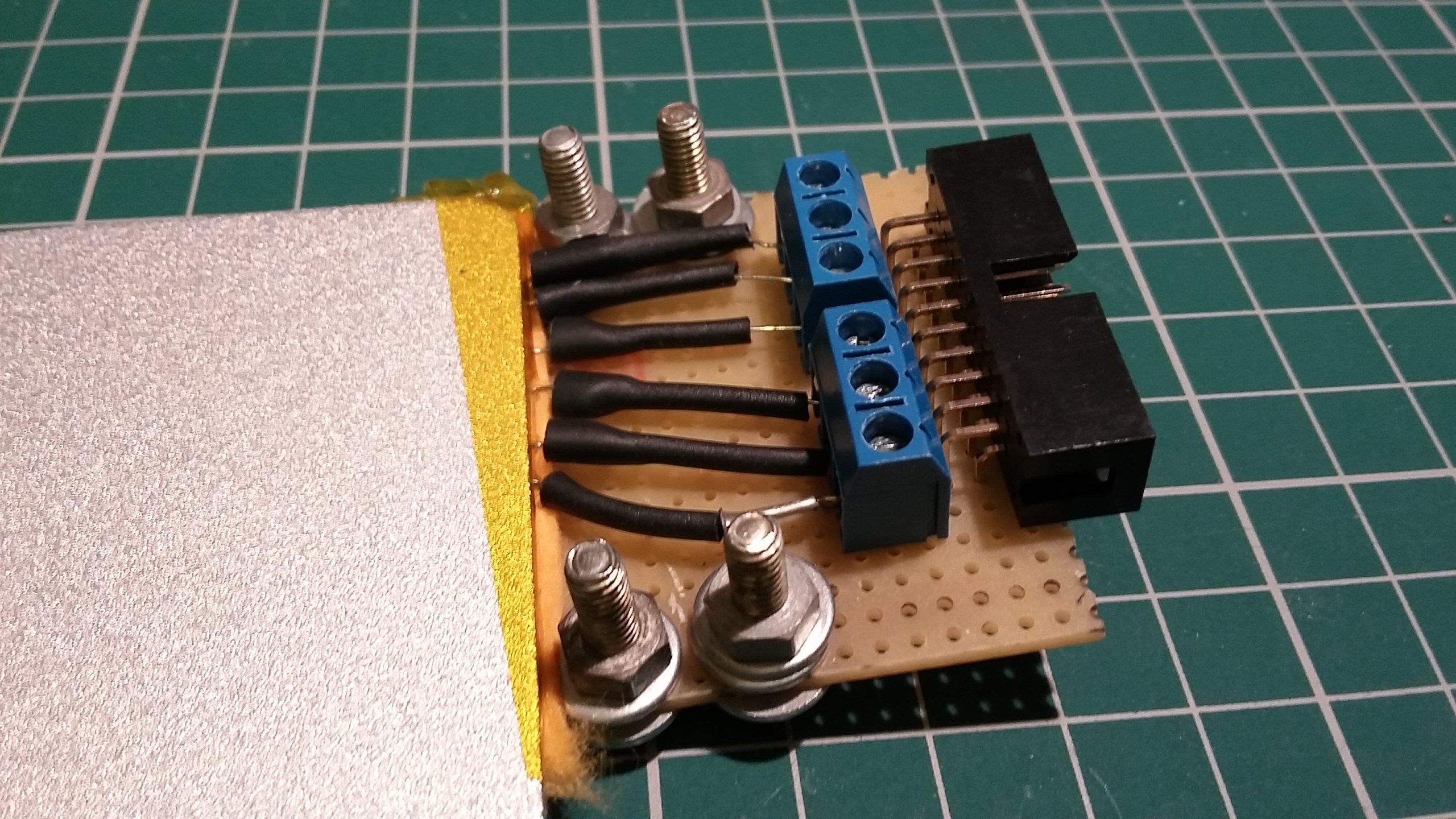

I have replaced the temporary connection with something a bit more permanent and pretty:

The piece of "super absorbent floor cloth" will be replaced with a piece of silicone matt as soon as that arrives in the mail. Then I will finally rest 100% assured that nothing will catch fire.

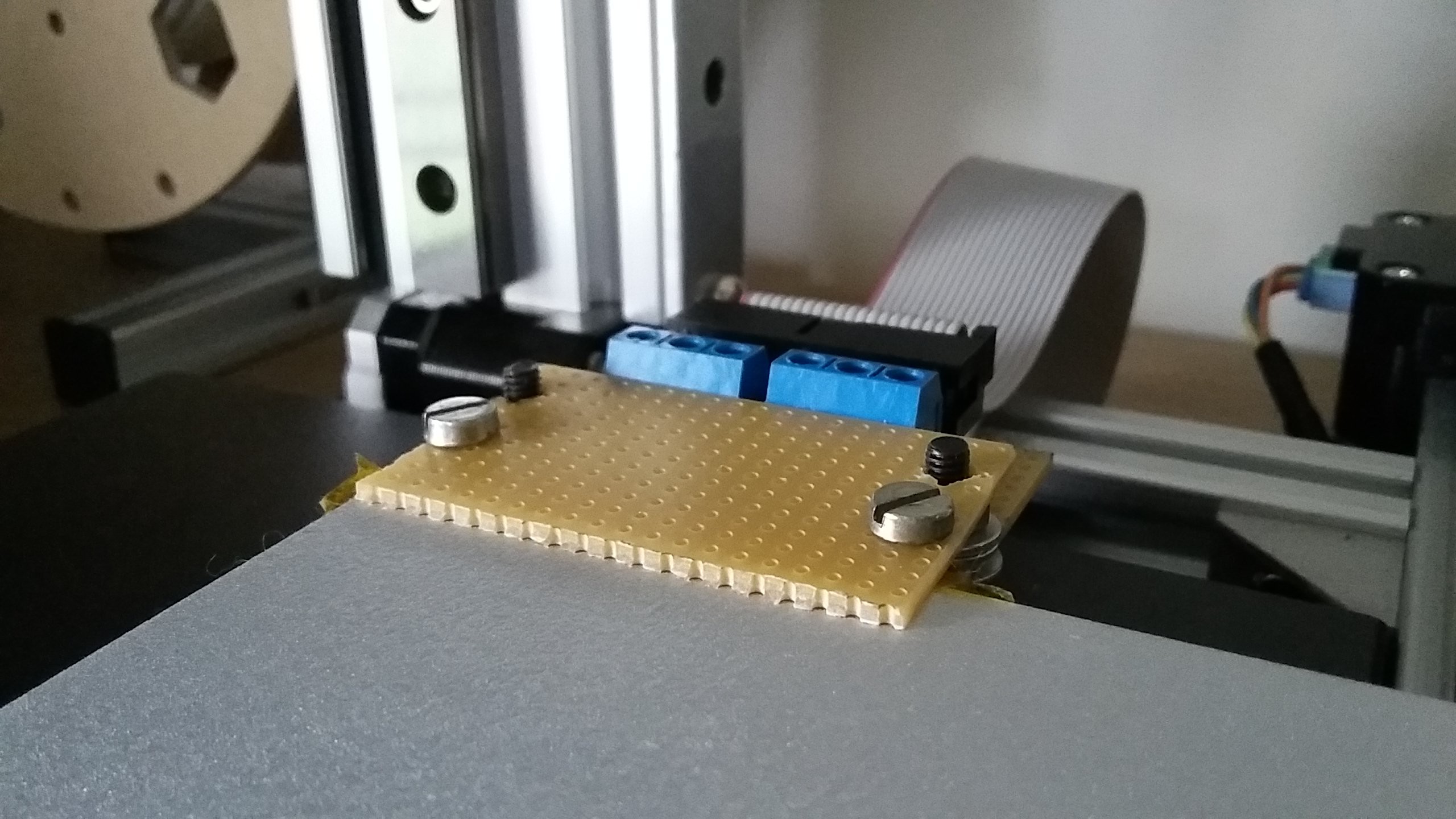

Unfortunately, this setup still interferes with the print head:

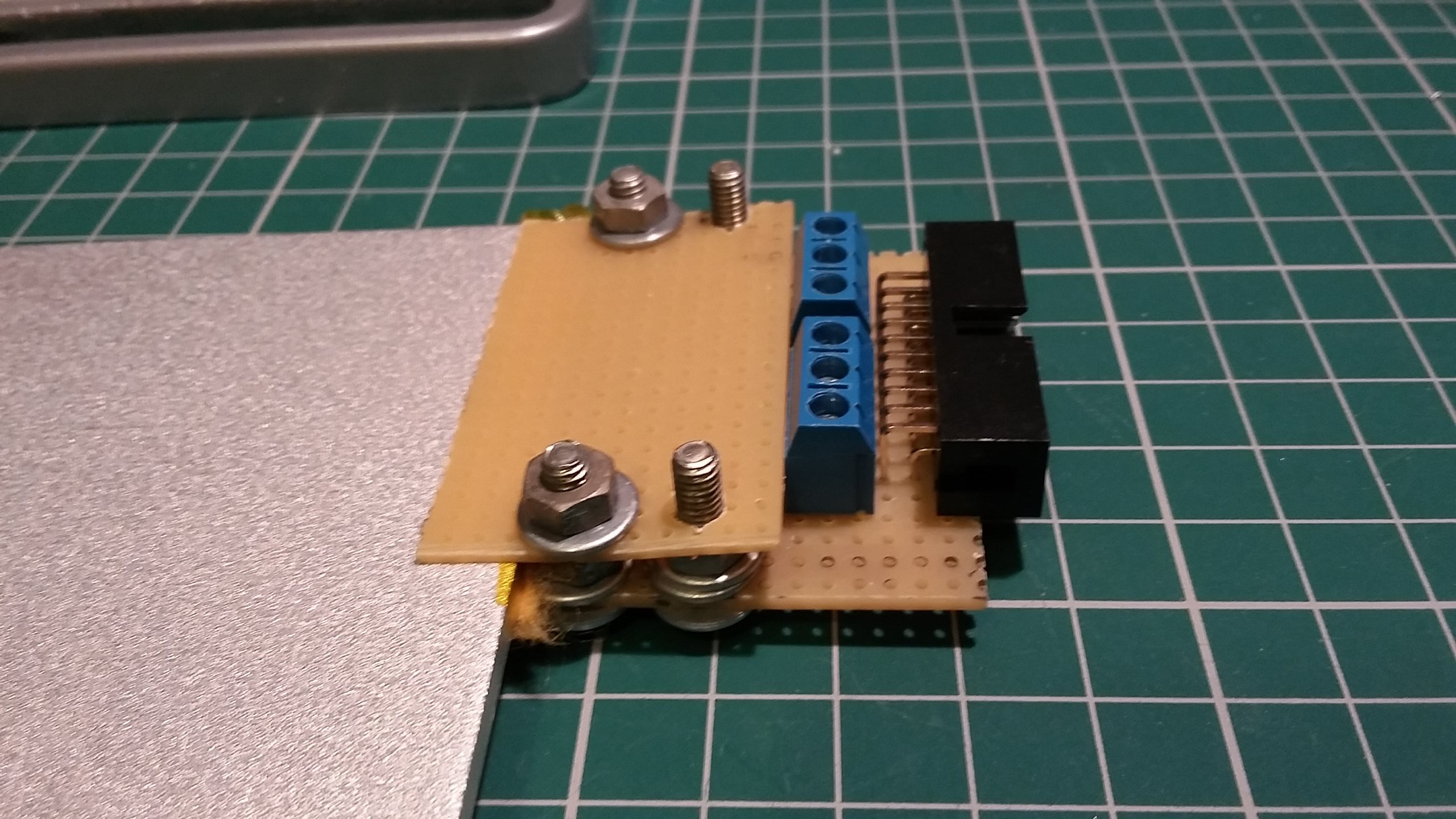

After replacing two screws with slightly shorter ones, and flipping two others around, at least the y-axis is no longer a problem:

Still, because of the interference with the print head, I lose about 4cm x 9cm of print bed real estate. Something that could be improved with screws with flatter heads. Maybe counter sunk heads would fit. Or I could try to grind the heads of two screws down to size. Could be a bit of a pain though, without a belt grinder or something similar.

UPDATE2:

I managed to grind and cut down some screws with my rotary tool fixed to a vice.

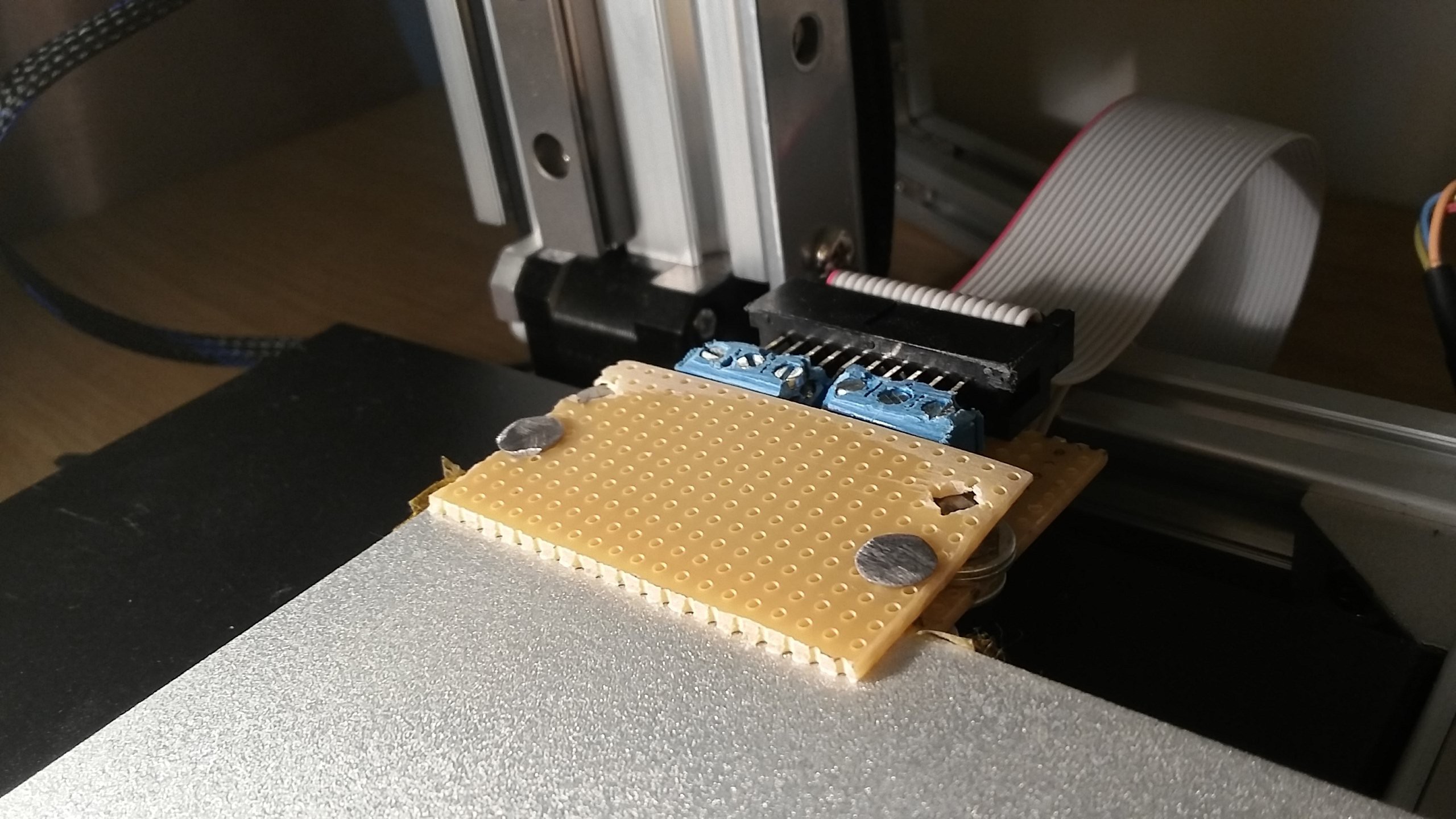

Now the only thing left interfering with the printer is the terminal block:

UPDATE3:

After some work with my trusty side cutter and a file, I reduce the height of the terminals so everything juuuuust about fits

It's not pretty, but it works. I guess that concludes this project!

Lukas Koch aka Ast

Lukas Koch aka Ast

Mark Rehorst

Mark Rehorst

Eno423

Eno423

Dylan Radcliffe

Dylan Radcliffe