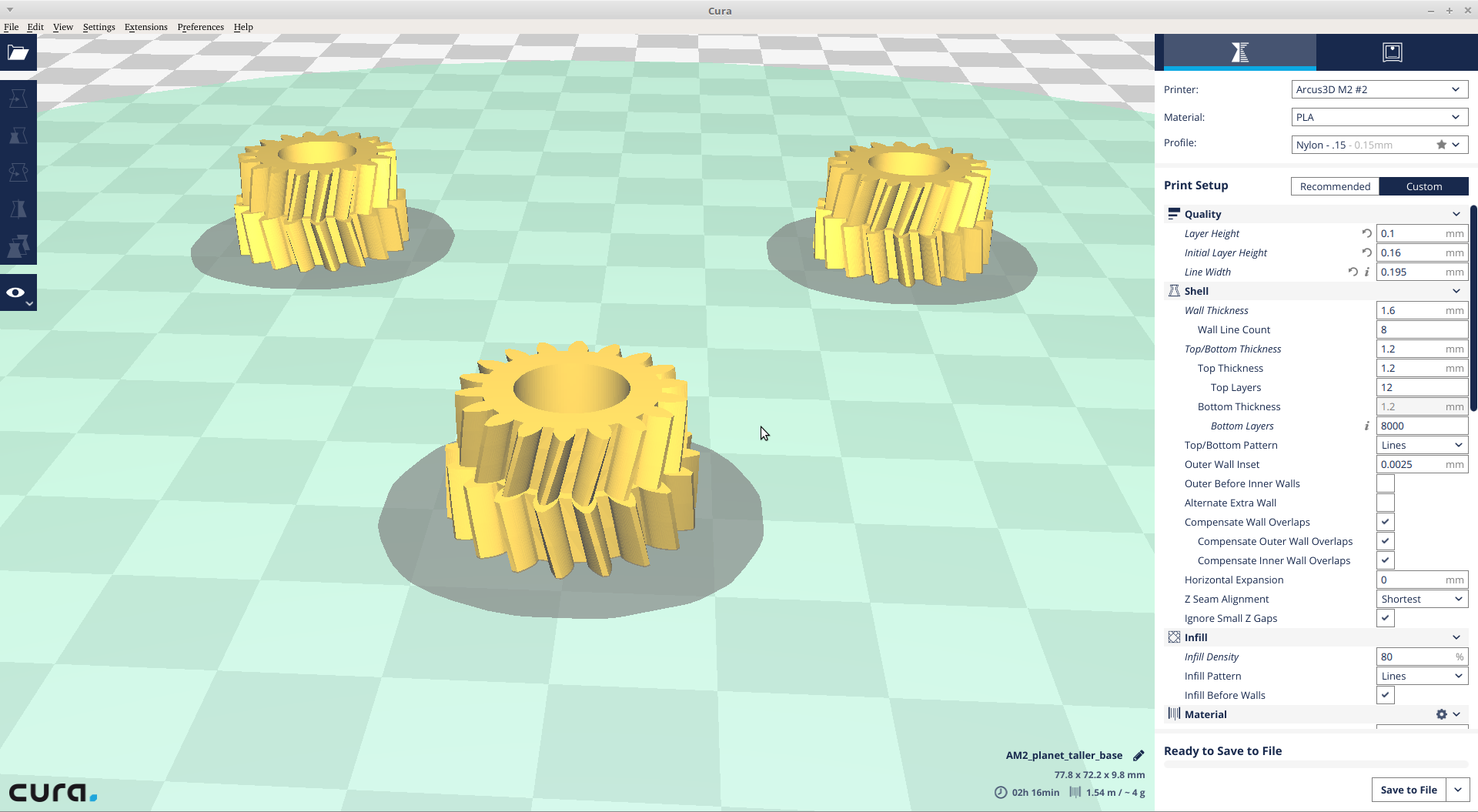

Down to printing the nylon planets now.

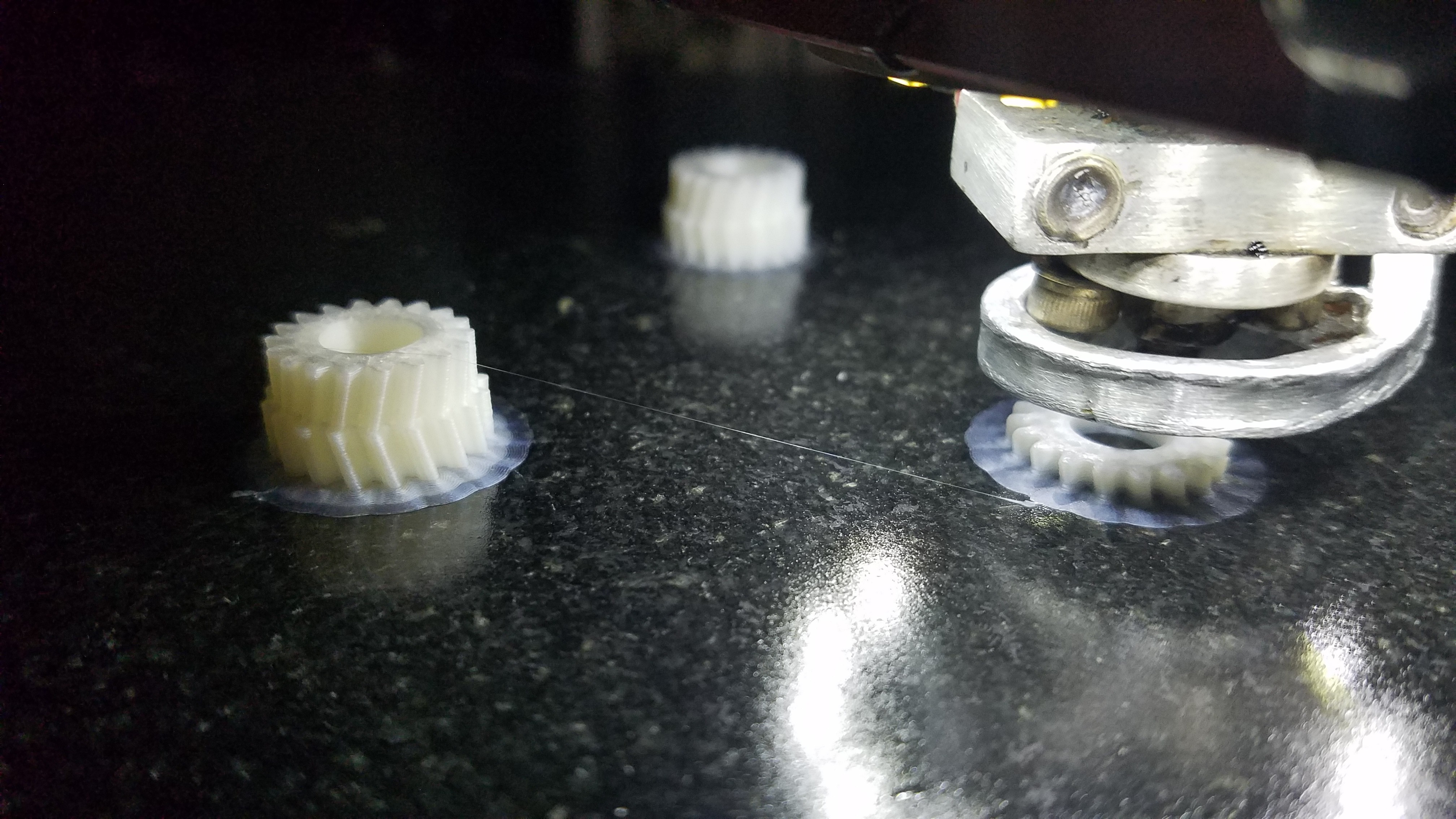

Printed out two of the planets so far.

The first was a bit too hot at 270C. Lowered that to 260C for the second and it's good.

My layer adhesion wasn't that great, so my roll of nylon is spending the rest of the day in the dehydrator first.

<EDIT> Four hours seems like enough dehydrating to bring my nylon back. No popping noises as I extrude.

I altered the model a little to simplify cleanup of the planets. When using nylon, I basically have to print these with a brim or they don't stay down. Removing said brim after printing is a PITA. But, I have found that if I print the first layer decently fast I can peel the entire first layer off the part very cleanly after printing, along with the brim.

So the model now has the clearance factor removed for the planet gear end which sits against the bed so it is now naturally 0.2mm taller than it should be. On removing my first layer of 1.6mm I'm right about where I should be for my gear height and no tedious gear cleanup. Yay.

I have previously modeled the brim over-extrusion factor right in, by adding a 45 degree slant inward at the bottom of the gear teeth. I don't really want to do that here as it will allow planets which want to tilt already a lot more freedom to do so.

Printing!

</EDIT>

<EDIT2>

The planets were turning out so well, I decided to go with 6 instead of 3. It was modeled that way anyway.

Two more to go...

</EDIT2>

MasterOfNull

MasterOfNull

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.