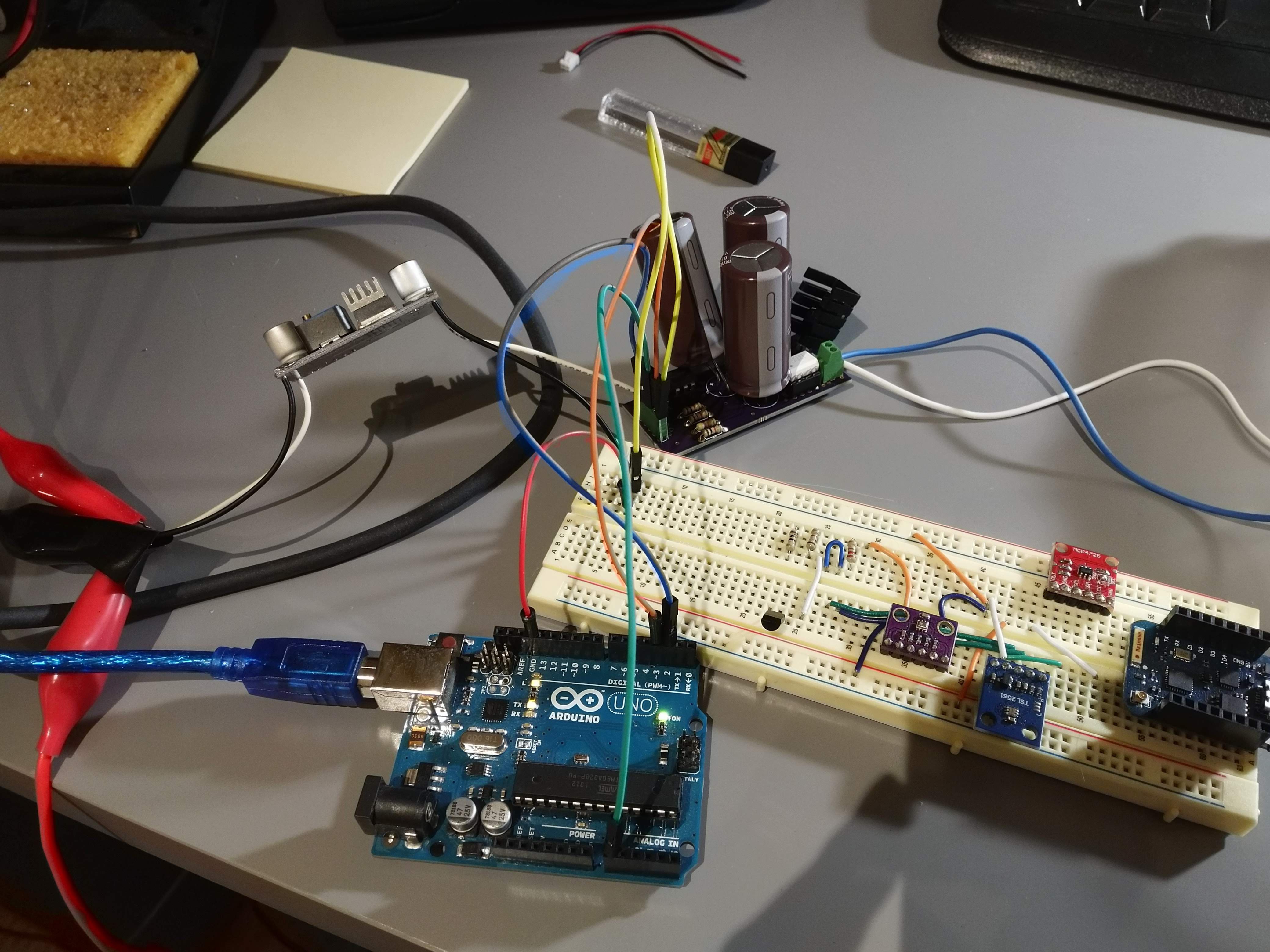

In the previous testing we've done we have typically hooked the electrode directly to the high voltage output of a current limited power supply. It works, but a light touch is necessary or the system purely shorts, current limits, and stops cutting. We had hypothesized that perhaps we could get better cutting by modulating the signal. In fact, it seems most commercial EDM machines modulate the voltage as well. In addition, we had hoped that this system could run off of the 12V supply on most hobby 3D-printers. Therefore, I built a quick prototype with an off-the-shelf boost converter (Amazon cheap XL6009 style) to achieve 30V+. A optically isolated solid state relay charges some large capacitors, then we can drive an optically isolated MOSFET to do the cutting. A voltage divider allows us to measure the capacitor voltage. Below is an image of the whole setup. An Arduino Uno drives the system. The input to the boost converter was 12V limited to 1A.

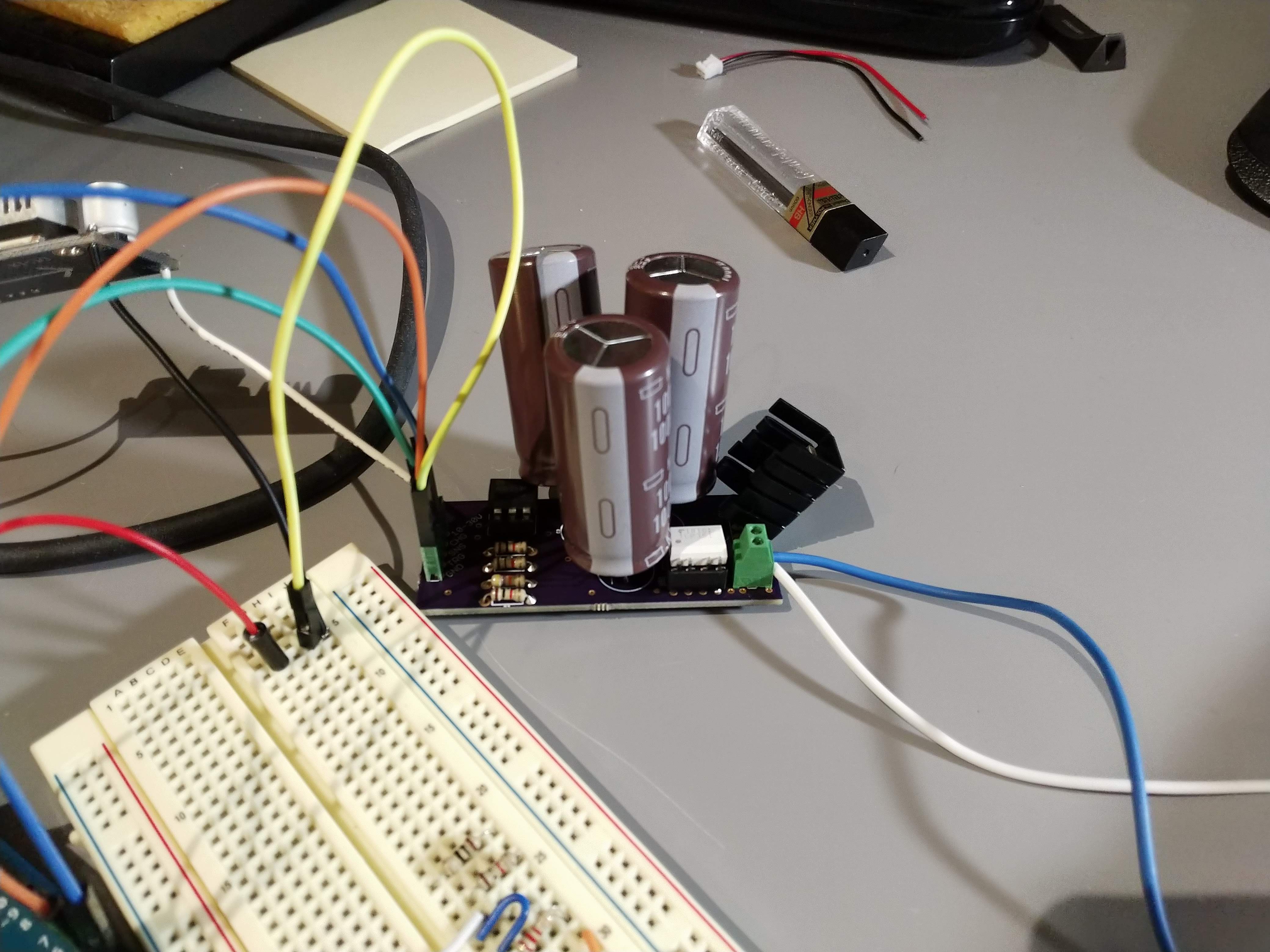

Even my prototype shows why I need this system. I somehow messed up sizing the capacitors and bought much too large versions. Each capacitor is 1mF, 100V rated. All in parallel there is a total of 3mF. I used three in parallel to lower the overall ESR so they can discharge fast. I charged them up to 37V with the boost converter. The Uno first charges up the capacitors until they reach some voltage. Then, it disconnects the charging circuit and switches the mosfet to discharge the capacitors. The average power needed by this system is not very high (seems <3W), but peak power is high. By alternating, the hope is this will shift the peak power handling to the power MOSFET and capacitors that can handle it, and away from the power supply.

Even my prototype shows why I need this system. I somehow messed up sizing the capacitors and bought much too large versions. Each capacitor is 1mF, 100V rated. All in parallel there is a total of 3mF. I used three in parallel to lower the overall ESR so they can discharge fast. I charged them up to 37V with the boost converter. The Uno first charges up the capacitors until they reach some voltage. Then, it disconnects the charging circuit and switches the mosfet to discharge the capacitors. The average power needed by this system is not very high (seems <3W), but peak power is high. By alternating, the hope is this will shift the peak power handling to the power MOSFET and capacitors that can handle it, and away from the power supply.

The test was highly successful. In the gif below, I'm pushing relatively hard onto the PCB, and it is not disrupting the cut. Best of all, the system runs from the 12V supply, reporting about 0.14A, so only 1.7W. There likely is some spiking higher that I do not see, but the power buffering seems to avoid that. This is really encouraging, that this system is:

- Simple to drive

- Low power

- Doesn't need careful force control to keep cutting

- Even with modulation, we can cut quickly

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.