For a metal gear drive motor, easy to attach to wheels via servo horn, I modified a "no stop" servo motor.

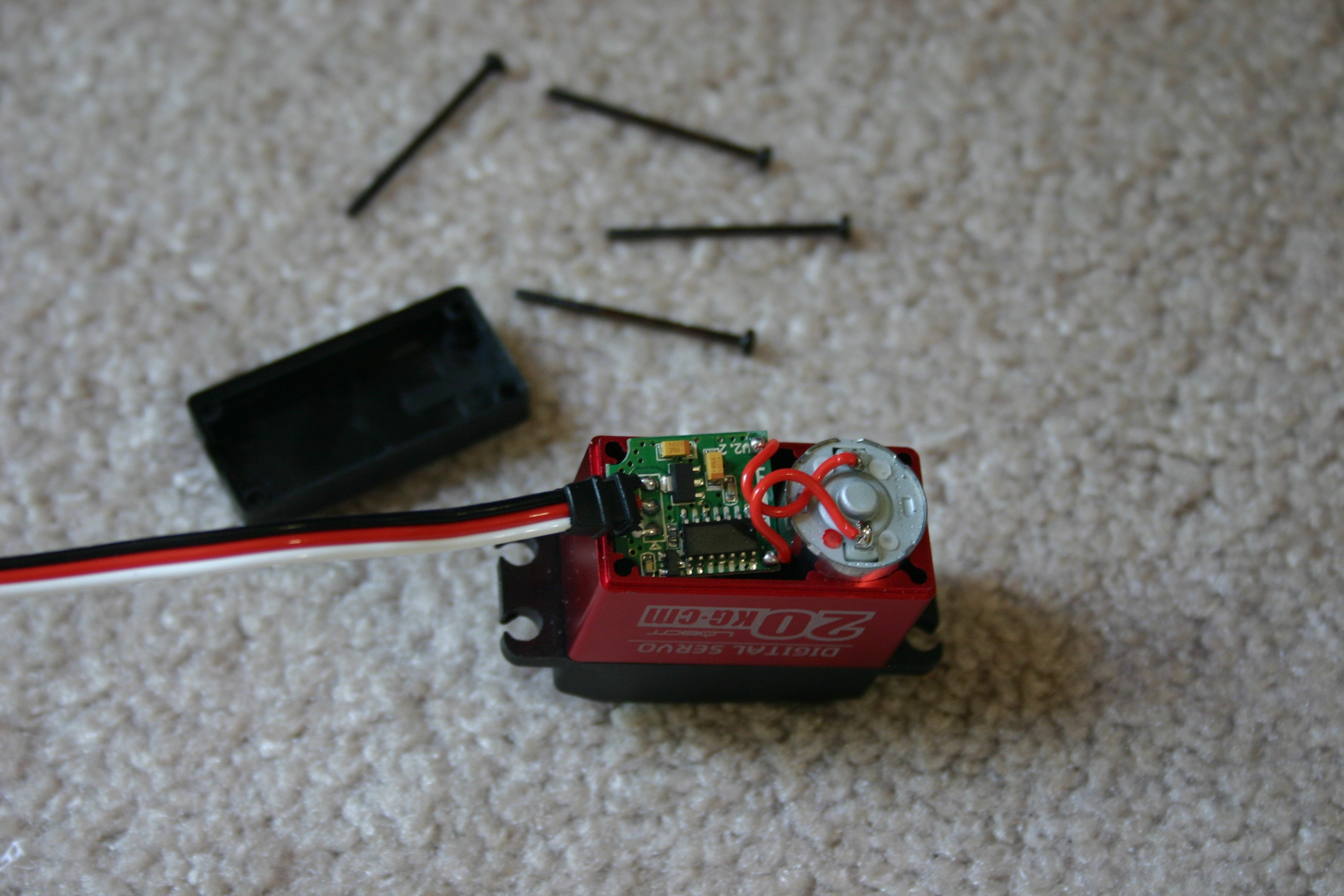

Start by removing the four screws in the bottom of the case.

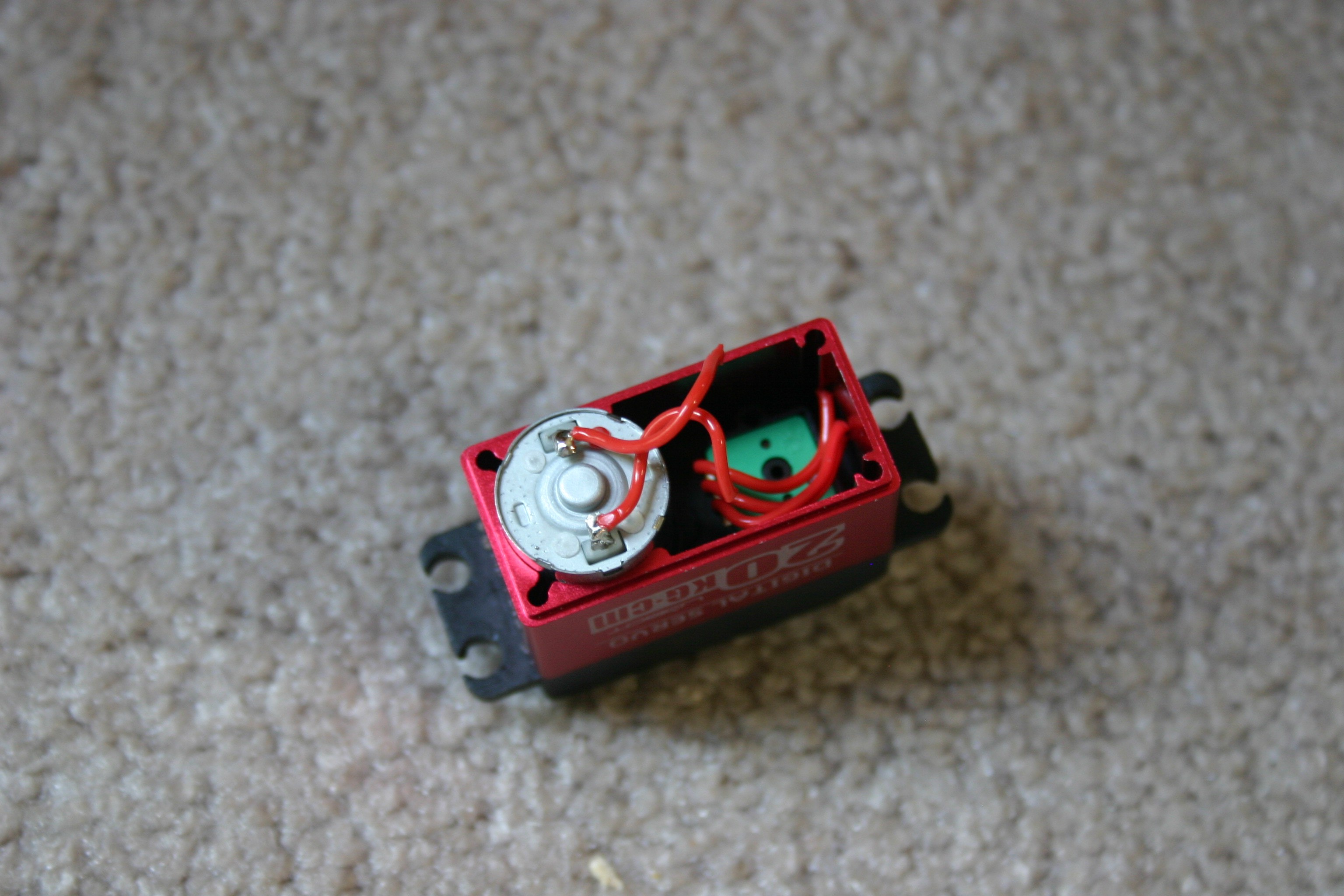

Next, cut the two wires from the circuit board that go to the motor.

Cut the three wires from the circuit board to the potentiometer. Remove the circuit board.

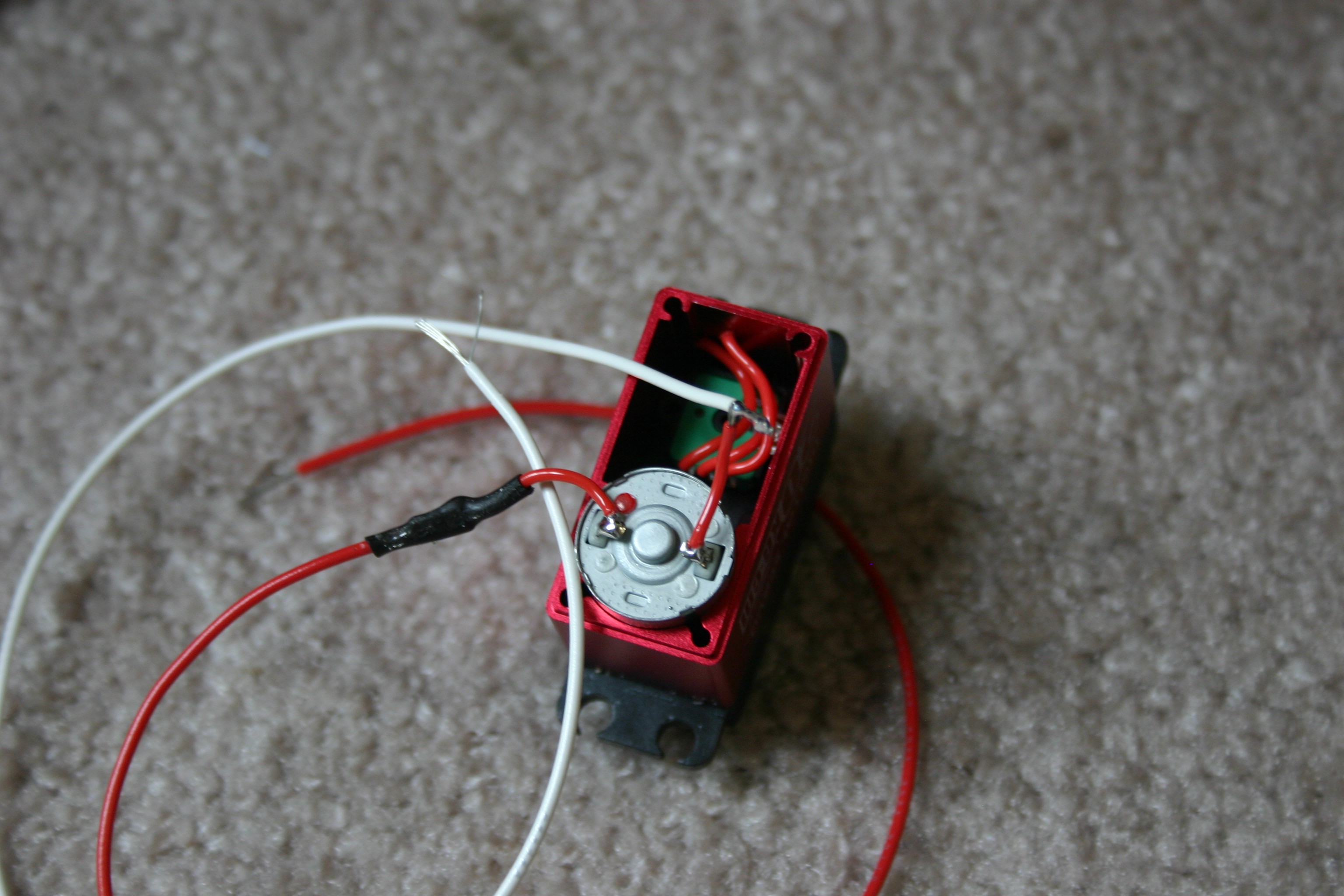

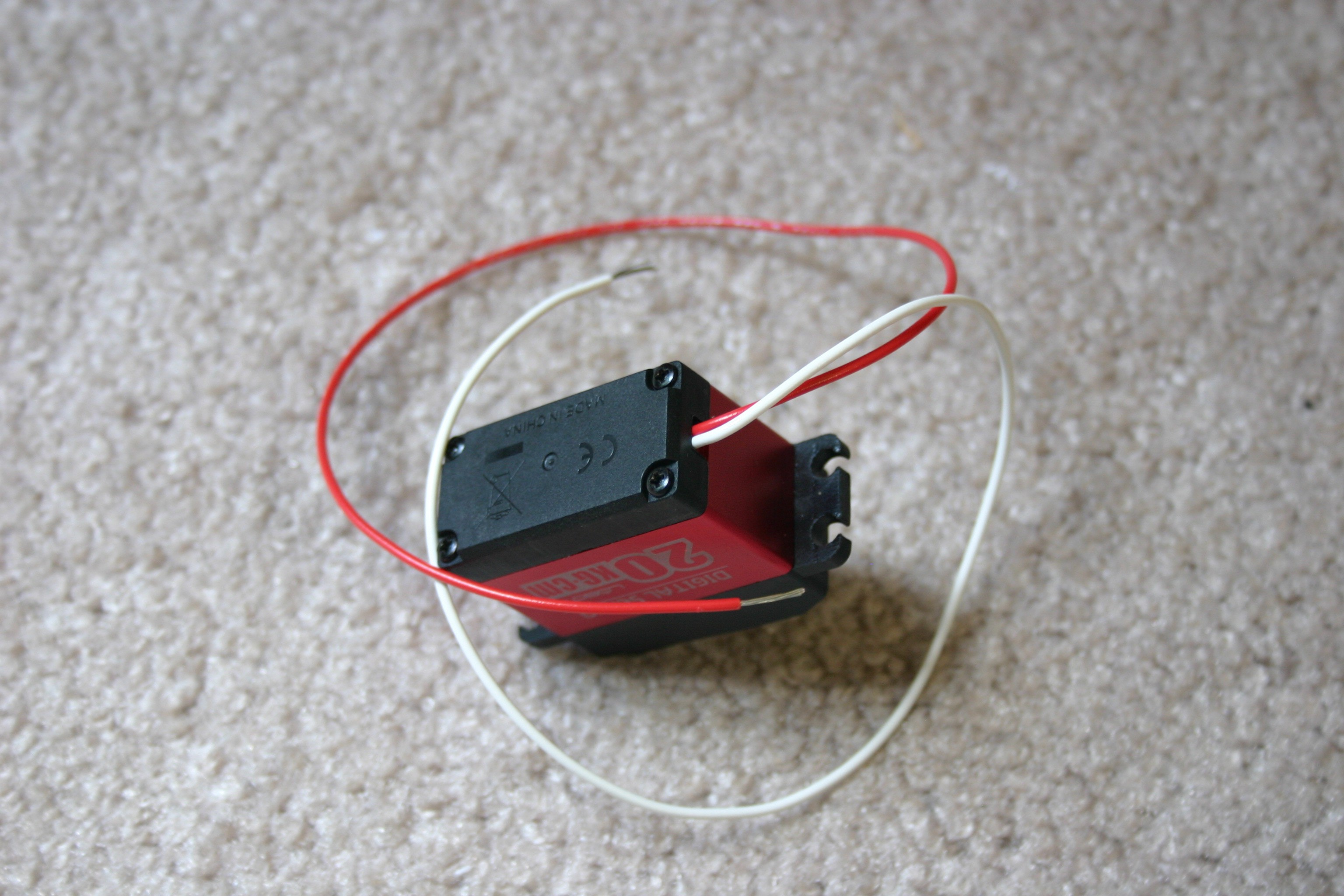

Take the two wires from the motor and solder extender leads.

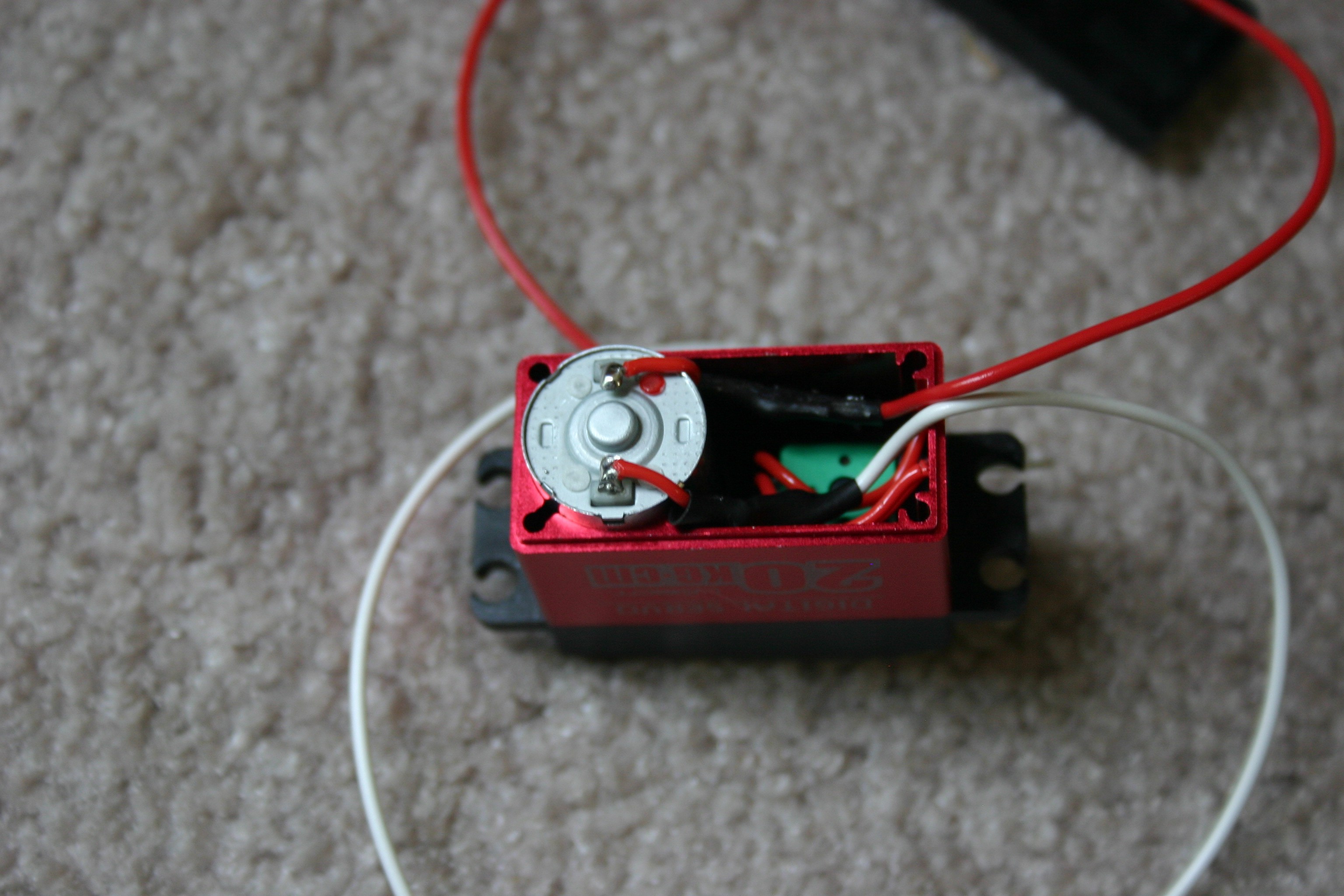

Push the solder connection joints into the cavity of the servo motor housing.

Screw the bottom cover back into place.

Mike Rigsby

Mike Rigsby

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

Interesting . . . I just tried this on a motor and you are correct. I can eliminate the Arduino motor shield--now I'm going to look at parts/cost reduction--just to see what I can do.

Are you sure? yes | no

You can also buy the same servo's already modded which could also speed up your pipeline. They are usually the cheap analog versions of the servos though.

The one you picked is a good one... You can drive those with up to 400Hz PWM and they work great. That's 8 times faster than the normal servo update rate.

You can push most analog servo's to about 300Hz, but jitter and overshoot get a lot worse. That may not apply to the continuous rotation modification though as you are basically eliminating the active feedback element. You'll just have to try it.

Good luck.

Are you sure? yes | no

Why? You can mod the same motor to also handle the H bridge power requirements with 2 resistors and just send it PWM.

Are you sure? yes | no

https://www.youtube.com/watch?v=lCgEugQDUBE

Are you sure? yes | no