Made a few modifications to improve a few issues.

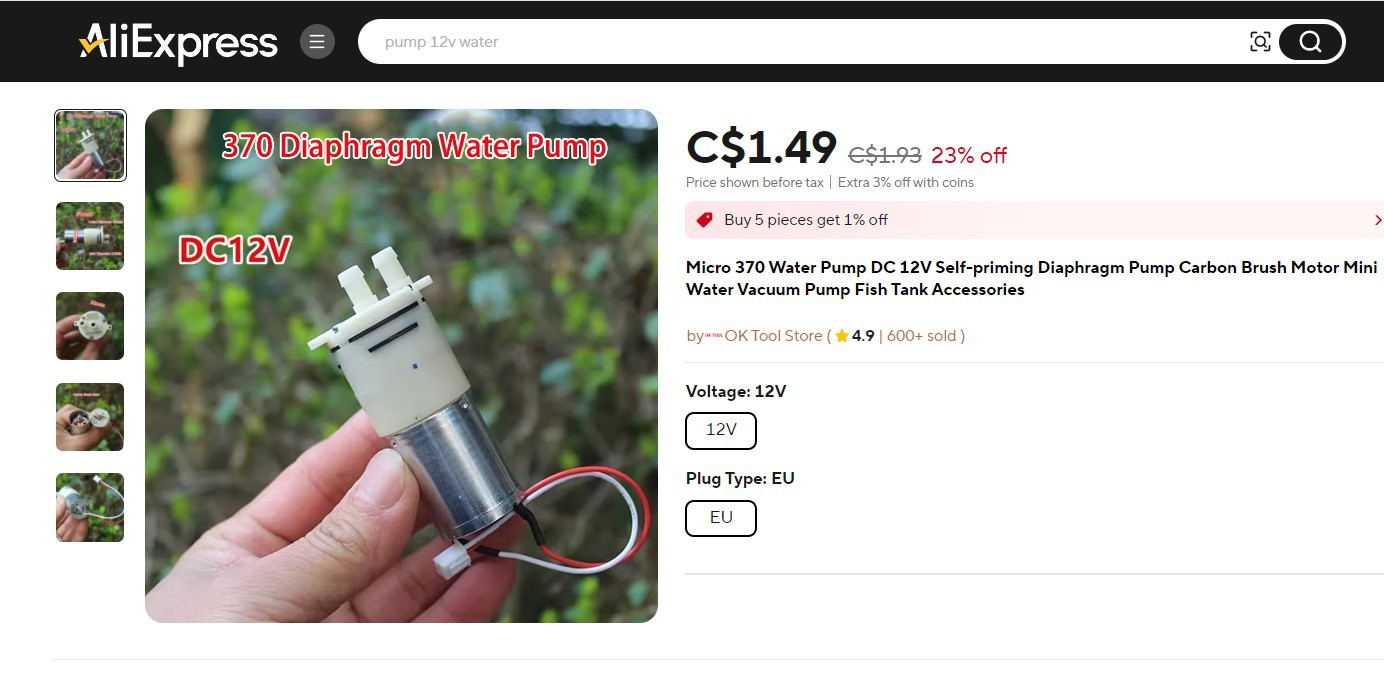

Switched to an even smaller well pump. They last 1-2 years. Peanuts cost.

Switched from copper tubing to 20 ga stainless steel wire for the well level sensor. The copper tubing corrodes after a year or so. The copper wire also corrodes if inside the casing due to the humidity. Ran the stainless wire all the way up so the copper connections are above and outside the well casing.

Original copper tubing for sensing water level zip tied on either side of plastic tubing.

New stainless wire sensor instead. Binder clip controls height of sensor when in the well. Adjusted to turn on the small pump at a low level but turn off before sucking air. Sensor goes to analog input A0 on NodeMCU. Highest number is 1024. Pump turns on at 250 level and off at zero or after 20 secs. On for 20 secs and off for 200 secs is a typical cycle. When the barrel is full the pump is off for hours so the level goes up to 500 or more. The blue tube and black clamp is to hold the intake filter down as it floats.

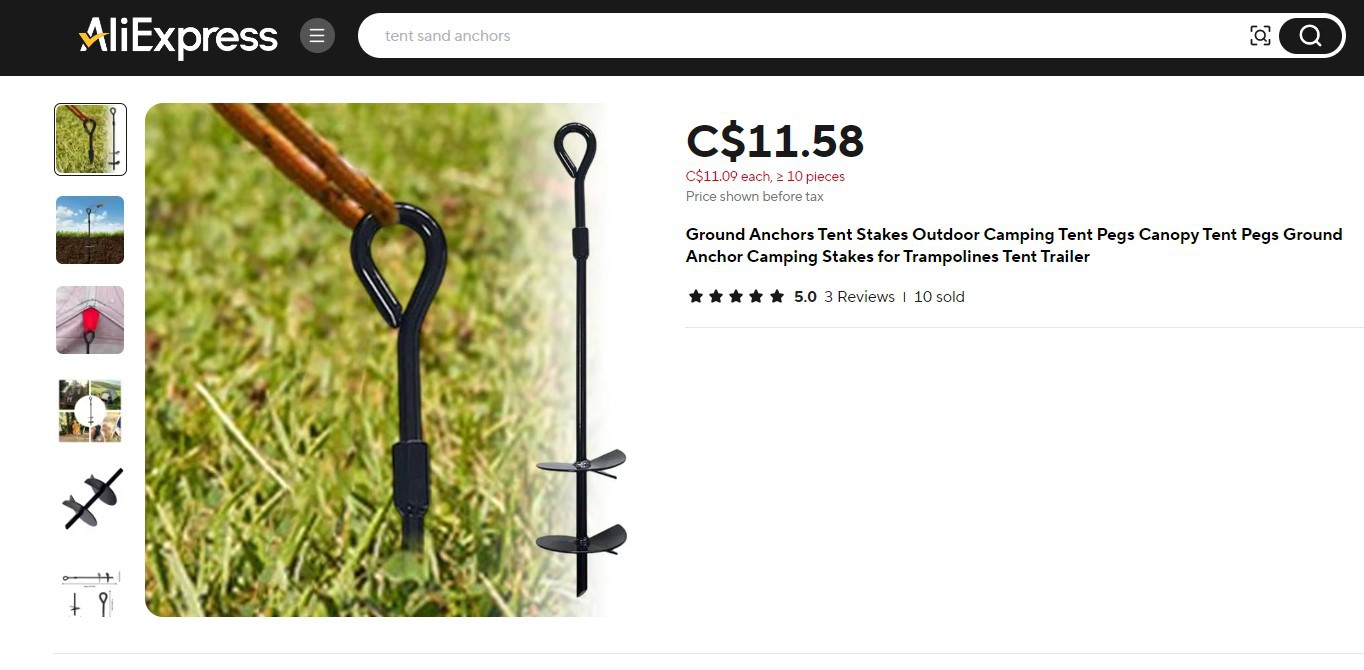

In July and August the well would run dry and I'd have to switch back to municipal water. This year I decided to go a bit deeper so the system can operate all year. The original hole was dug with a 6" hand auger then the 4" plastic casing installed. I didn't want to remove the casing, only drill within it, so I bought a tent anchor with 3" dia. dual flights and bolted it to a steel tube I had. The water intake filter is 2.5" dia. at the bottom of the well with the 1/4" plastic tube inside it. The end of the green steel tube broom handle is notched to engage with the edge of the top flight. It worked really well to drill through the muddy soil at the bottom of the well with the mud sticking between the flights for removal. I only had to go another foot or so to get lots of water. I could easily go much further if needed in the future.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.