Frequency-modulated continuous wave radar is a technique of interferometry for measuring distance (and speed with some post-processing) of objects by transmitting a frequency modulated signal and measuring the difference in frequency between the delayed receive signal and the (currently transmitted) reference signal. When two signals close in frequency interfere, they produce a beat tone. The frequency difference between transmitted and received EM waves is measured by interfering the waves and measuring the envelope of the beat tone they create.

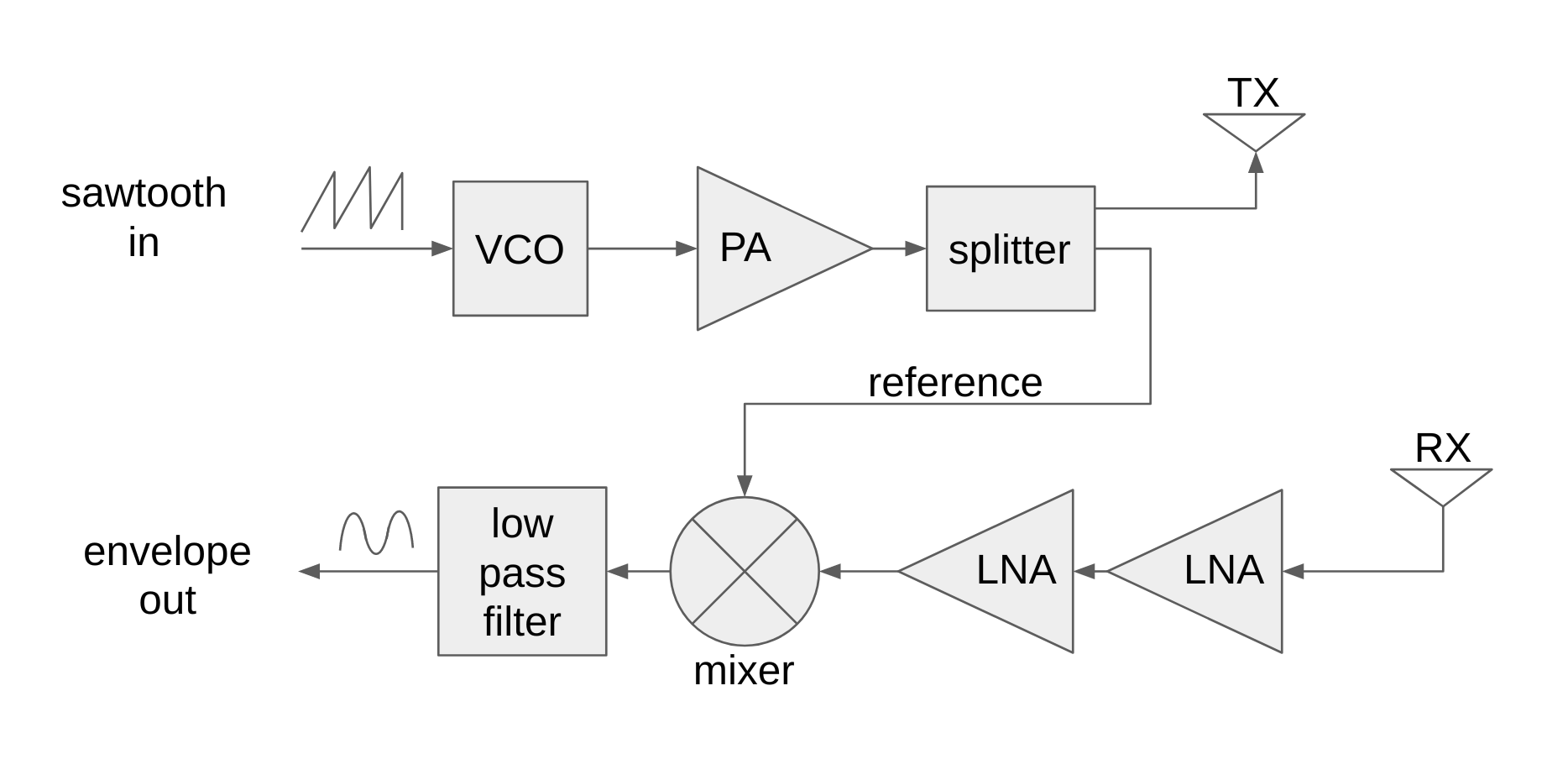

The architecture of an FMCW radar is shown below:

The main focus of this project was the design and implementation of the power splitter and mixer circuits.

The splitter is a coupled-microstrip directional coupler. When a voltage (and current) travels down a PCB microstrip, there is a corresponding electric field (and magnetic field) between the microstrip and the groundplane on the opposite side of the dielectric substrate. In the center of the microstrip, the electric field is uniform, but towards the edge of the microstrip it fans outwards, spilling over the boundary of the copper microstrip. This has the (potentially undesirable effect) of allowing two microstrips that are physically close together to couple power through fringing electric fields. In the case of power couplers and splitters, this is quite advantageous, and by adjusting the separation between the two strips, the amount of power that is coupled between the strips can be adjusted to a desirable value.

For the purposes of our project, we wanted very weak coupling between our microstrips because whatever power that is coupled is not transmitted, and since the power is coupled after the transmit amplifier, we wanted to maximize the power transmitted. This meant we had a relatively large separation between the two coupled microstrips.

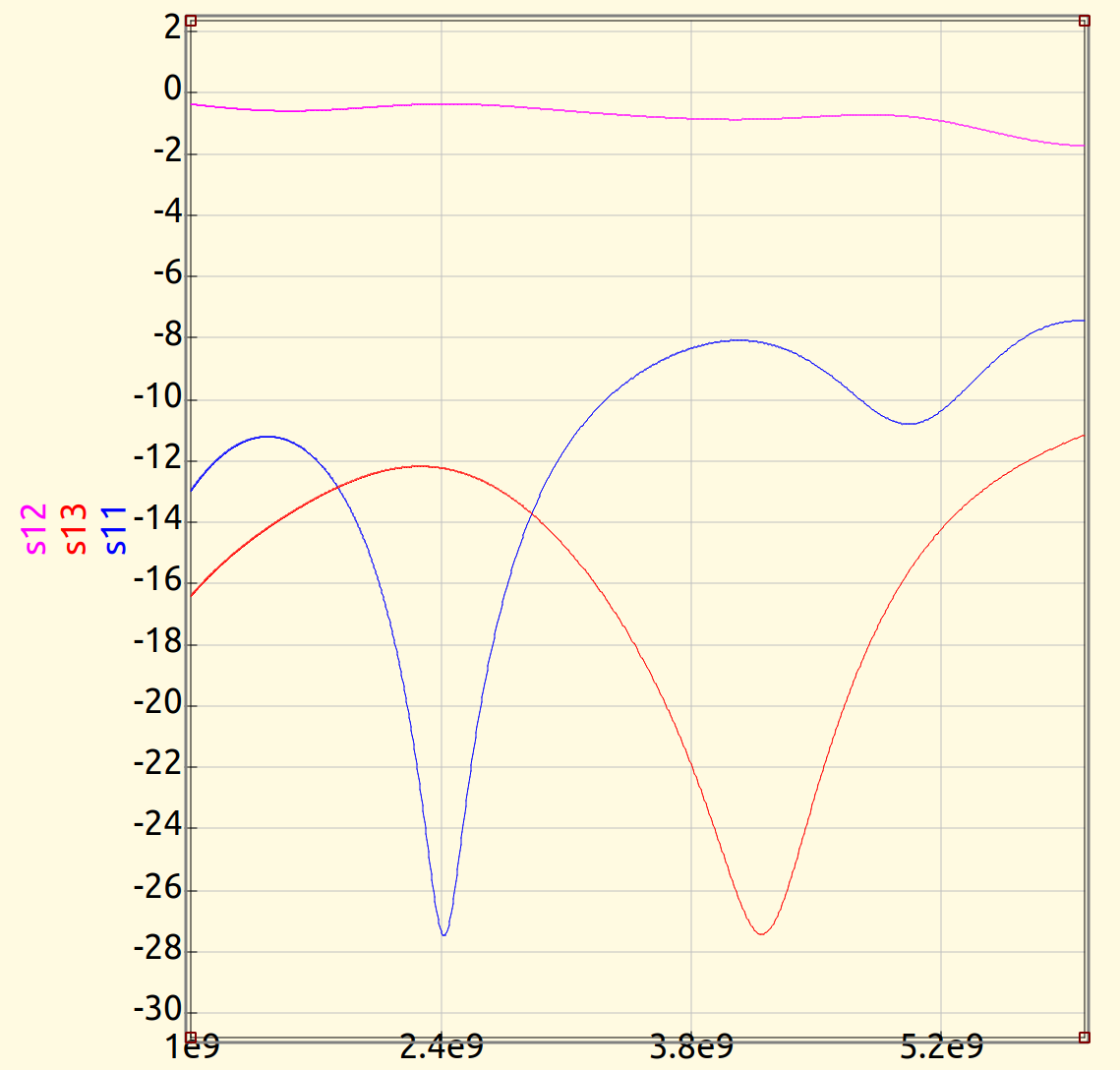

Using Qucs (Quite Universal Circuit Simulator), we determined dimensions for the microstrip coupler and attached traces (some of which were impedance transformers to match our 50Ω design) which provided optimal scattering parameters for our purposes shown below:

The vertical axis is magnitude in dB and the horizontal axis is frequency in Hz. The blue curve (S11) is power reflected by the coupler, which we see is minimized around the center frequency of our radar design (which is desirable). The red curve (S13) is the power coupled through the coupler. -12dB coupled corresponds to about 6% of power coupled. Nearly all power is transmitted as is shown by the pink curve (S12).

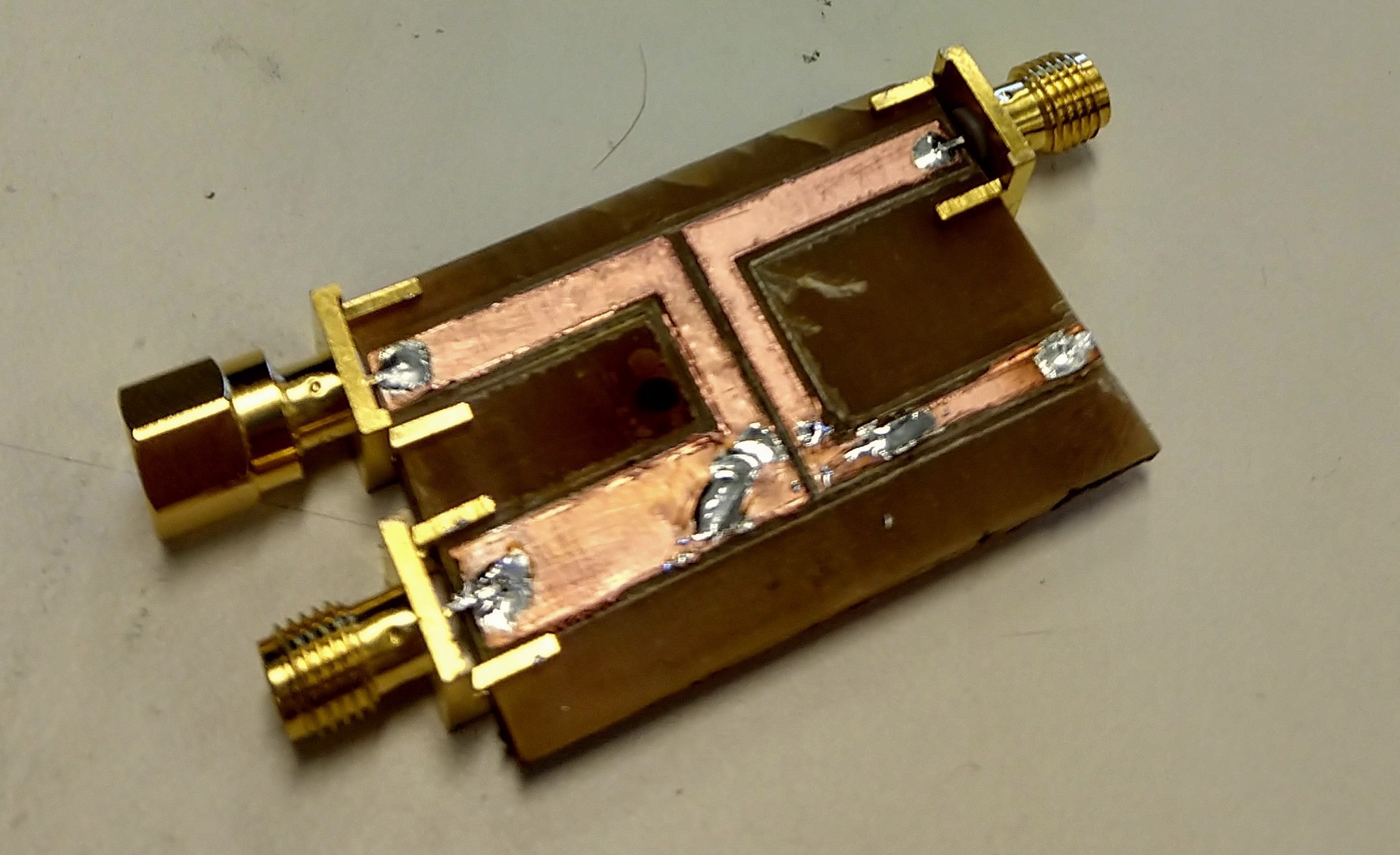

We milled a prototype on FR-1 substrate and measured its scattering parameters with a network analyzer. The prototype is shown below with one of its terminations disconnected — the termination was connected for testing (the burn marks were from heating up the board in an attempt to weaken the double-stick adhesive used to stick the board to the mill):

Unfortunately, the prototype we built was not perfectly centered at 2.4GHz and had a high reflection coefficient (-10dB), however it had decent power coupling (-17dB) and transmission (-7dB). Some of this loss (and reflection) we attributed to poor connection between our SMA connectors and the PCB.

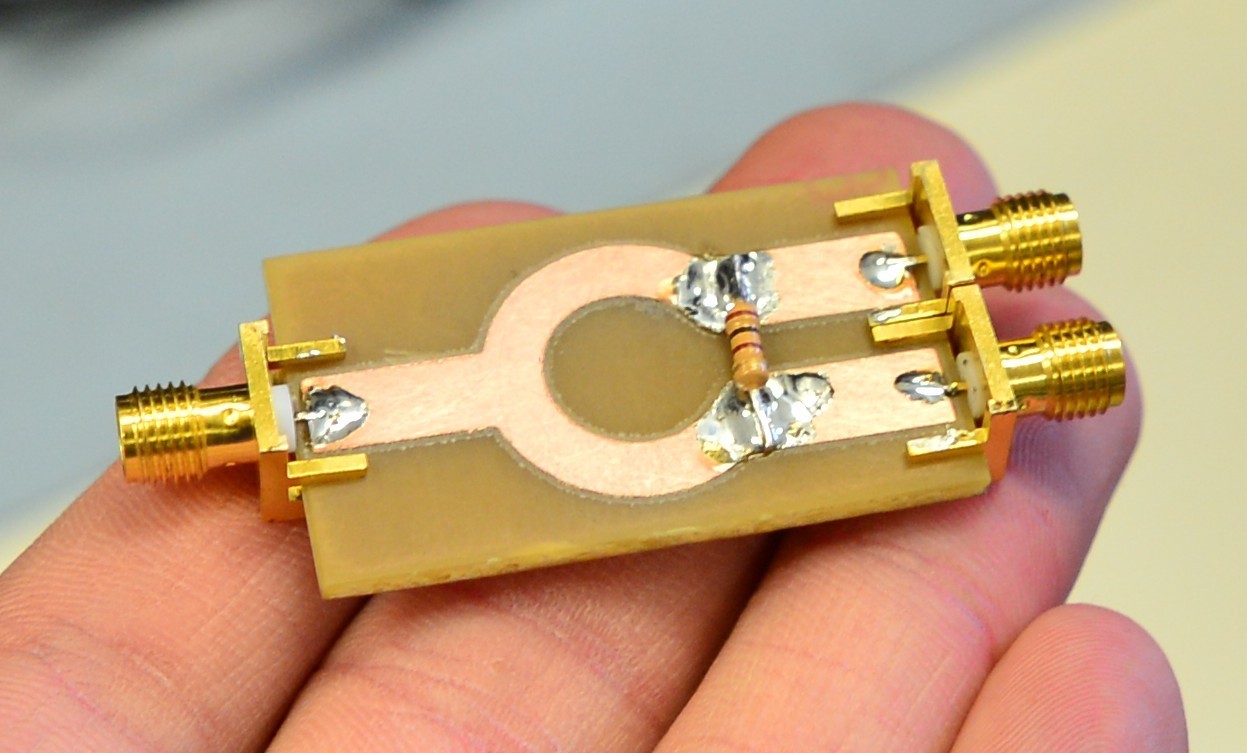

The mixer circuit consists of a summing mixer and a half-wave rectifier RC circuit to detect the envelope of the sum. The summing mixer is a Wilkinson power combiner which has the nice property of port isolation; the two input ports (on the right of the picture) are separated by a half-wavelength through the combiner and through the (ideally) zero length resistor, any power through one input port will destructively interfere with itself at the other output port.

Our prototype pictured below (which we milled out of FR-1; somehow it turned out far more aesthetically pleasing than the coupler) achieved -25dB isolation at 2.4GHz, however it had a peak isolation of around -35dB closer to 3.5GHz, indicating that coupler was physically too small for the properties of our substrate; the loop is not quite a quarter-wavelength at the lower frequency of 2.4GHz.

After testing the RF microstrip prototypes, we designed a board combining all the modules of our radar architecture. Instead of milling the board, we decided to etch it on FR-4 substrate (which conveniently has approximately the same relative permittivity as FR-1).

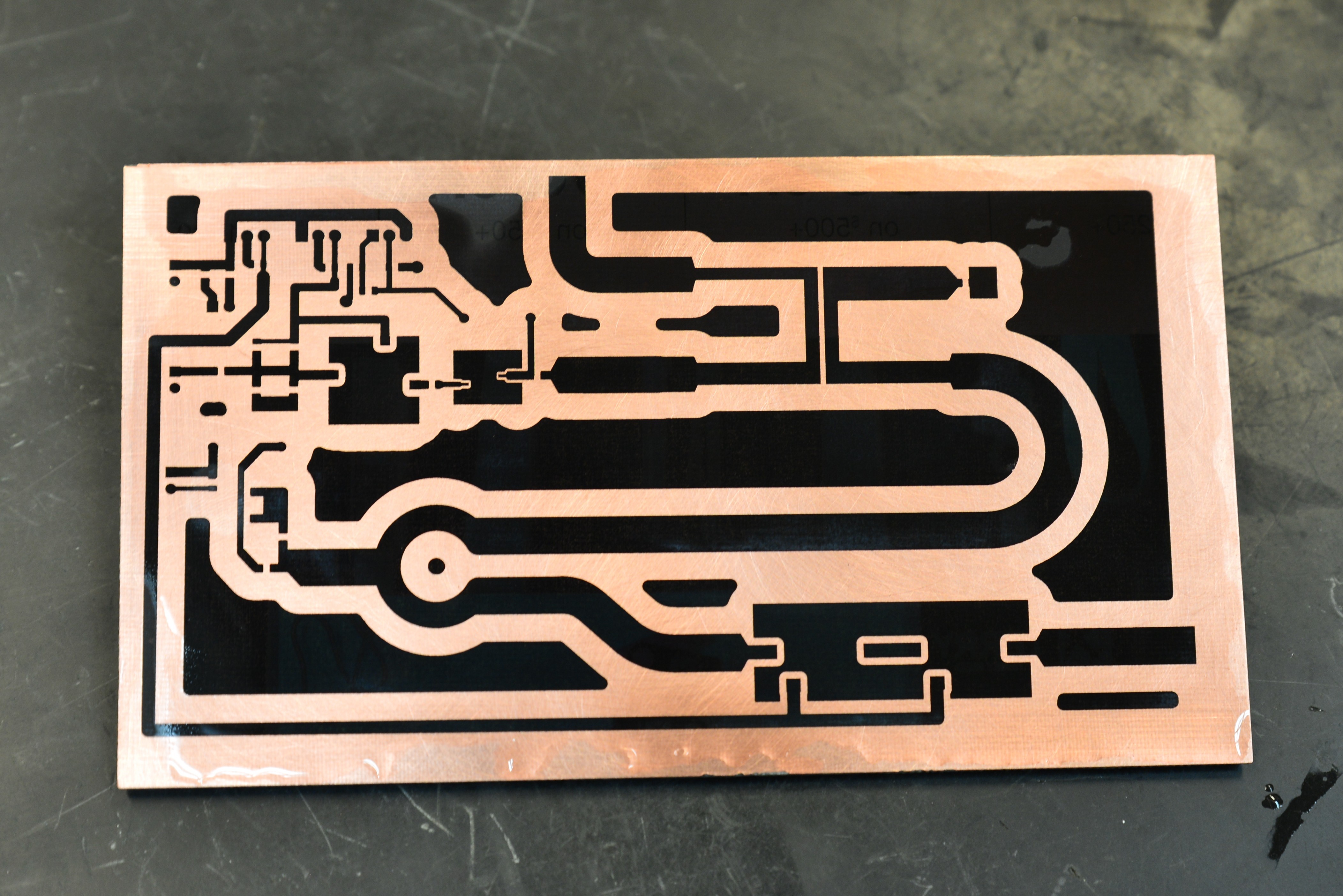

Here's a picture of the board post etch with toner still on the copper layer

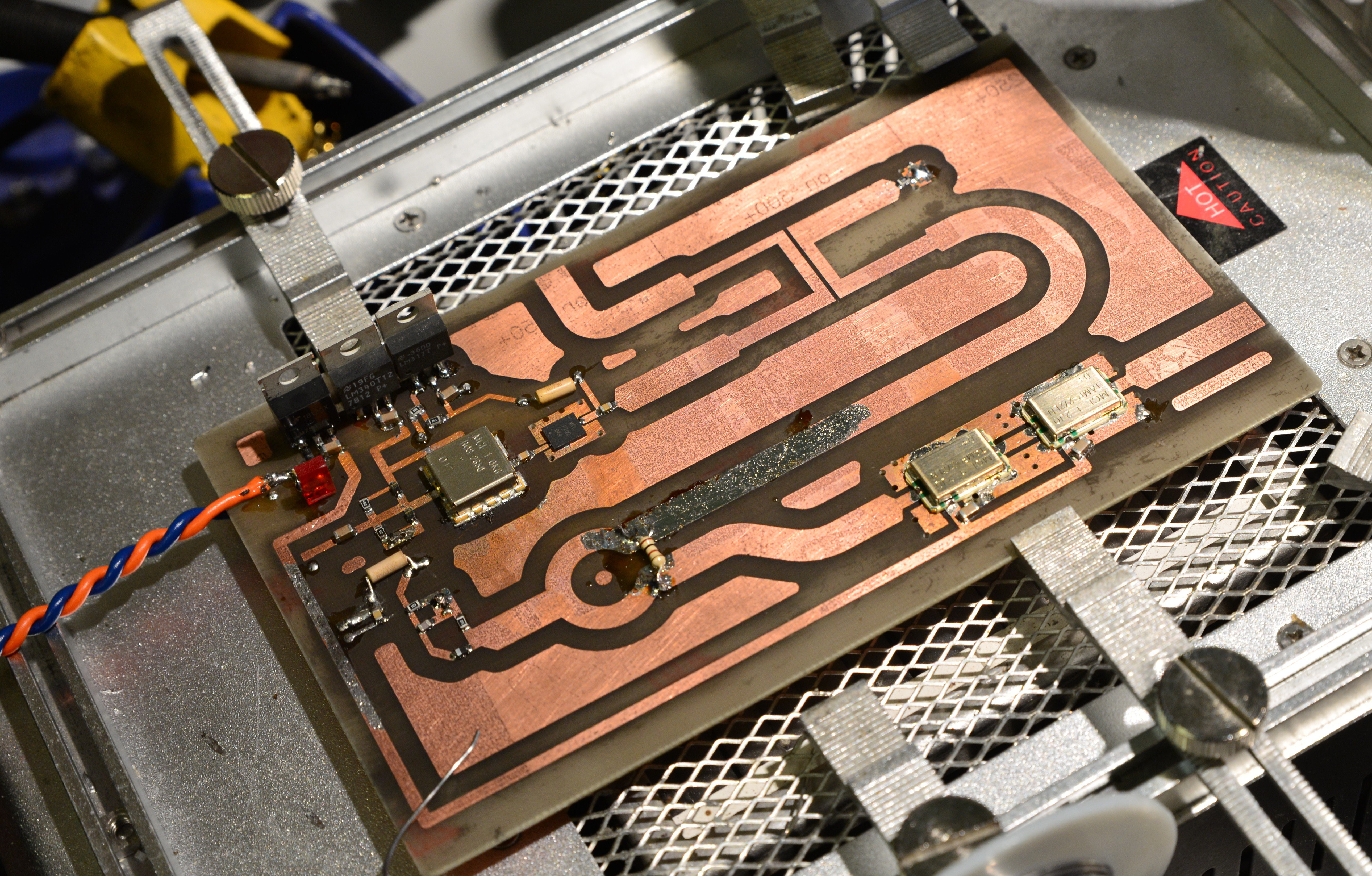

Hot air rework to reflow components:

We had a slight mishap when soldering the VCO on; since it wasn't a monolithic component, heating it up enough to reflow it melted the solder holding it together. This is not normally an issue, however it was bumped while the solder was molten and the metal shielding lifted up and reseated (although it seemed to still work fine when we powered it up).

When we finally finished populating the board (and the many painful grounding vias) and connected it to a function generator (supplying the tuning voltage to the VCO) and an oscilloscope measuring the voltage across the mixer output, we measured no beat tone whatsoever, even with a highly-reflective metal corner-cube (shown below).

At that point, our project was due in less than 36 hours and all we had to show for it was a non-functioning board and some results from prototype testing. We also noticed the power amplifier (on the transmit side) started to get very hot. After a quick datasheet check, we found that the (very) ambiguous datasheet didn't do a good job of distinguishing between recommended board layout and a bottom view of the package diagram. We ended up connecting the tuning voltage to ground and one of the ground pins was connected to a tuning signal oscillating between 6 and 12 volts. Somehow the amp still worked after we re-soldered it on in the proper configuration (we got lucky that simply rotating the chip allowed for us to connect the PCB traces to their proper pins. Despite fixing this, the result was the same; no beat tone with a stationary reflector.

However, we eventually discovered (after trying out just about every possible frequency modulation rate and even putting the board in an RF-shielded box) that moving the reflector resulted in a beat tone with frequency directly proportional to the speed of movement of the reflector.

This was unexpected but unsurprising, and was a tremendous result because it confirmed that the main focus of our project, the power splitter and mixer, worked — we had a doppler radar. The moving reflector creates a Doppler shift so that the received signal is at a different frequency than the transmitted signal, which we were able to measure with our mixer.

Since we bumped the VCO while reflowing, we hypothesized that somehow it lost its ability to modulate frequency, and somehow could still produce RF. We replaced the VCO with a new one, but still had the same result. Since the key parts of our project worked, we decided to scrap frequency modulation and turn in a working Doppler radar.

Reed Foster

Reed Foster