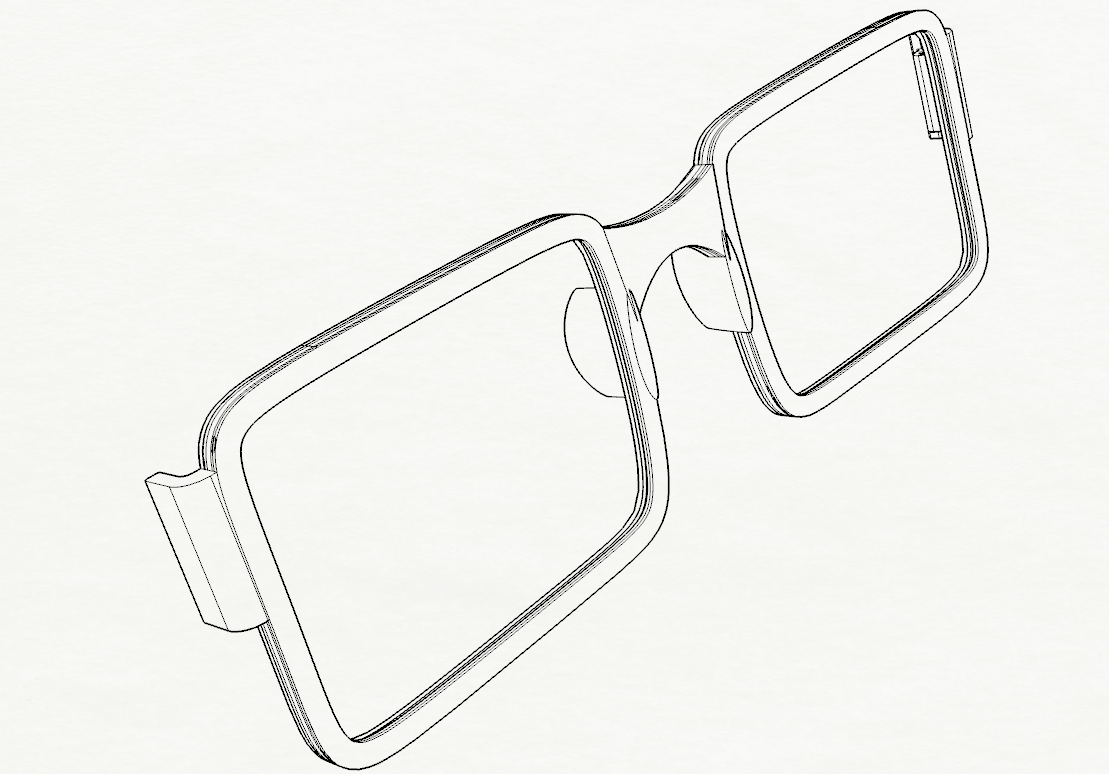

The new prototype; Stapler.

I recorded my design work. Two parts.

Part two:

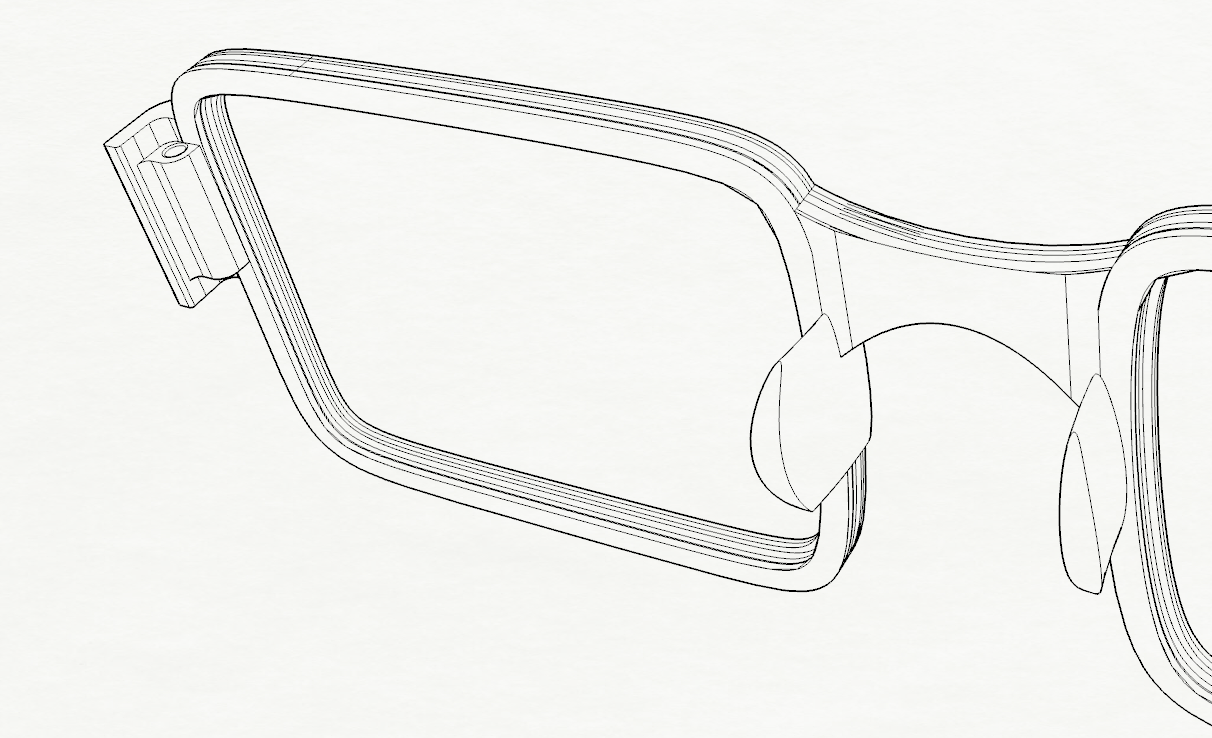

Change nose-pad shape. DONE

Open up arm wire diameter to 1.6mm+ DONE

Extrude half blind input by: .6mm (proportional to edge of arm support expansion. DONE .6mm

Eliminate arm-notch: <Switch to staple design> DONE

-------------------------------

Prototypes take an hour on average to process using current printer. Too slow.

Lens fitting and orientation is all done manually right now.

Only way to speed that up is with expensive tooling.

Goal: limited release in about 4 weeks.

Note; this is part two of this video, I needed to think about a design decision and to switch to no audio for a bit.

I have decided to go with a staple type arm, I will completely remake the arm supports so that the arm cannot flail outwards. I’ll make an illustration after showing the model. Here we go.

Running low on ram.

Not filleting any further, makes more sense to do by hand.

David Troetschel

David Troetschel

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.