Laser Cut Design

Sent off the design to get cut in 3 mm Acrylic. I have some acrylic glue (have not used this stuff before). The fumes are known to be carcinogenic!

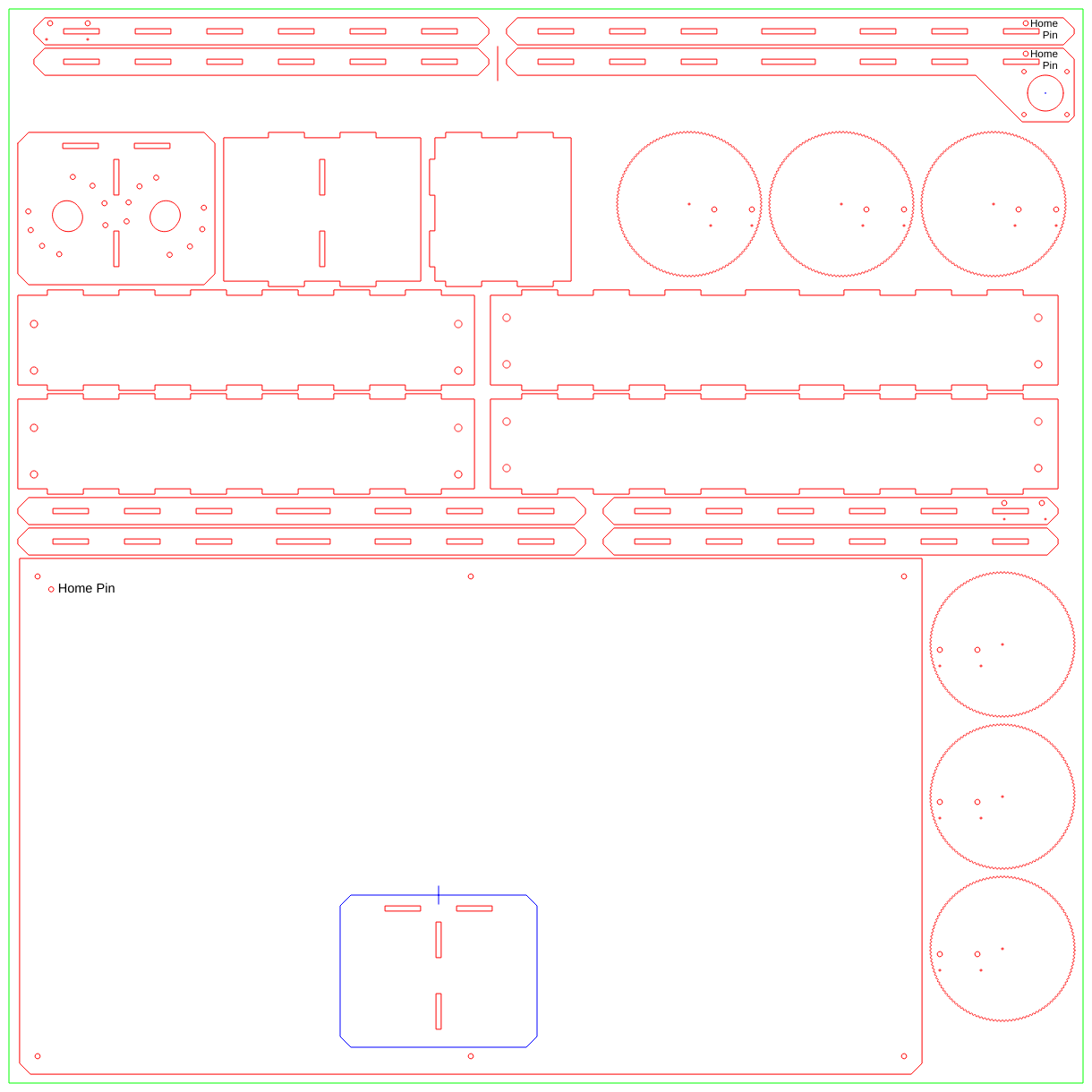

Here is the final work area:

For homing, I have put 3 mm diameter holes in the far arm and in the base board to lock the home position.

I have use an "I" section for the arms. Not that worried about twist with this design. The arms are offset vertically so that the I beams can "nest". I have include 1.2 mm diameter, alignment holes for the GT2 pulley:

Note: The green outline is just to show the acrylic outline.

Hopefully I have made no serious mistakes.

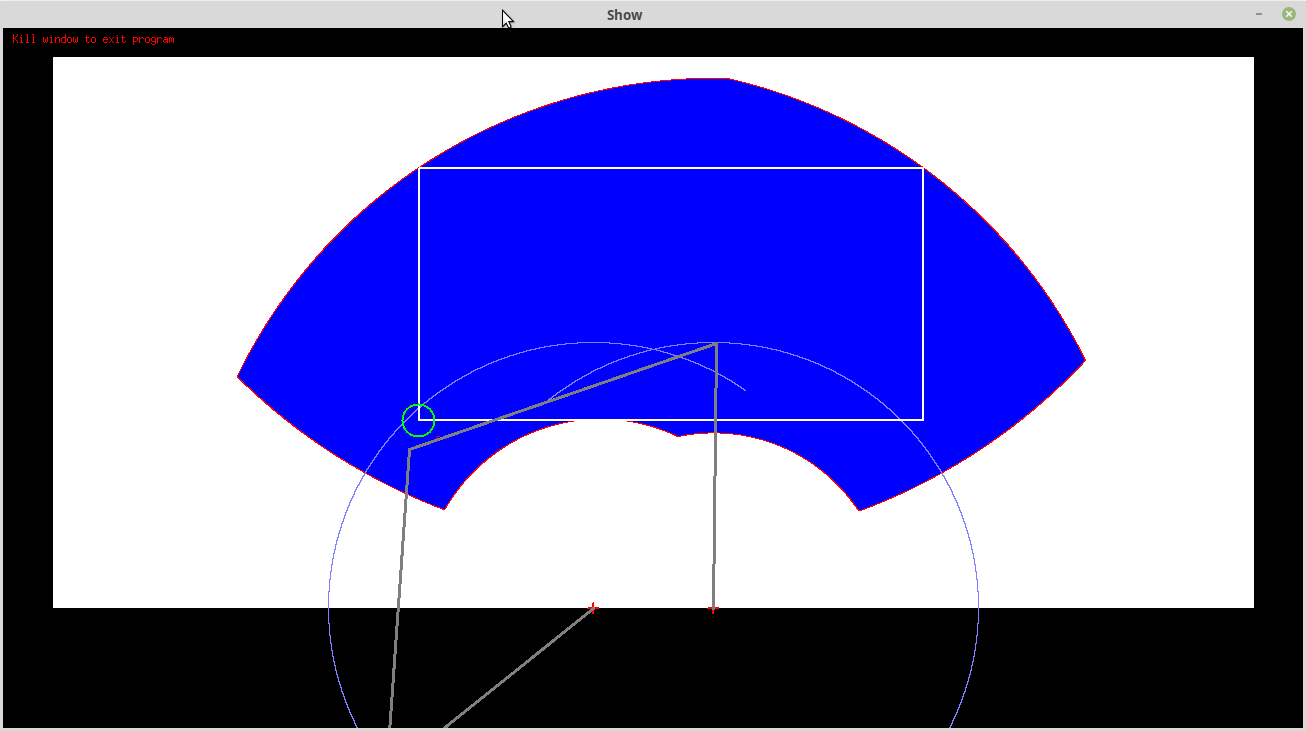

Ah, I just thought of something, I have not check if the laser module will fit in-between the arm webs!

Not as I hoped!

Well I got back the laser cut parts. But the fit was very poor. The acrylic melts rather than vaporizes. So the I had to file the edges. During the test fit, it would go together but was very hard to get apart. I broken one of the parts. Also I glued one part upside down.

I was not keen just to reorder the wasted parts. I am looking at buying some aluminium rectangular tube instead.

I have ordered some new plastic hinges from another source (much cheaper!), I am hoping the quality is better.

So just waiting for the parts to arrive.

Not all bad!

I glued the GT2 pulleys together, not too bad:

They look a little rough but they engage the belt fine.

Alan

agp.cooper

agp.cooper

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.