DFM is one of the most critical parts of any project, if you are aiming to mass manufacture the device eventually.

The typical route usually is to build a prototype which looks like the future product (“looks like prototype”), then build a working prototype (“works like prototype”), then blend both together and refine the product. And only then start DFM.

We, at BikeOn, prefer the other way around. DFM was in focus for us starting with design of proof of concept prototype. Some of the questions we have been constantly asking ourselves with every iteration of the design are:

- Is this the minimum number of parts to perform a particular function?

- Can some parts perform the function of other parts in any way?

- Has anyone ever designed subassembly with similar functions, and how?

- Part level: how many setups are needed to machine/manufacture the part? How to reduce the number of setups?

- What are alternative manufacturing techniques that can be used (for example, extrusion instead of CNC machining, water jet/laser cutting cutting blanks instead of CNC machining, vacuum forming instead of injection molding, etc).

...and many others. The goal is to get to the bare minimum, minimalistic yet highly functional design even at the level of the very first prototype.

The advantage of this constantly ongoing exercise is that the eyes and the brain learn to see and think in very minimalist and efficient way. The unnecessary details fall off the focus and design ideas become much clearer.

If we don’t go through these exercises routinely, we will be forced to do so eventually by our manufacturing partners, but at that point it may be too late, substantial redesign and changes may become inevitable and may even be dictated by the manufacturing guys rather than by us.

When we started designing BikeOn back in 2013-2014, one of the best prototyping tools we had was the 3D printer at local Techshop. And we printed a lot!

It was so useful, fast and important that we even purchased our own printer. Here is a review of it:

However, 3D printing has its downsides: certain shapes that can be printed on a 3D printer are not manufacturable using other techniques. That’s why we started working closely with our friend, the owner of a local machine shop. Even at the stage of part design he gave us invaluable feedback. It is very common for us to send him models of preliminary designed parts, asking for his opinion, feedback and even ballpark quote.

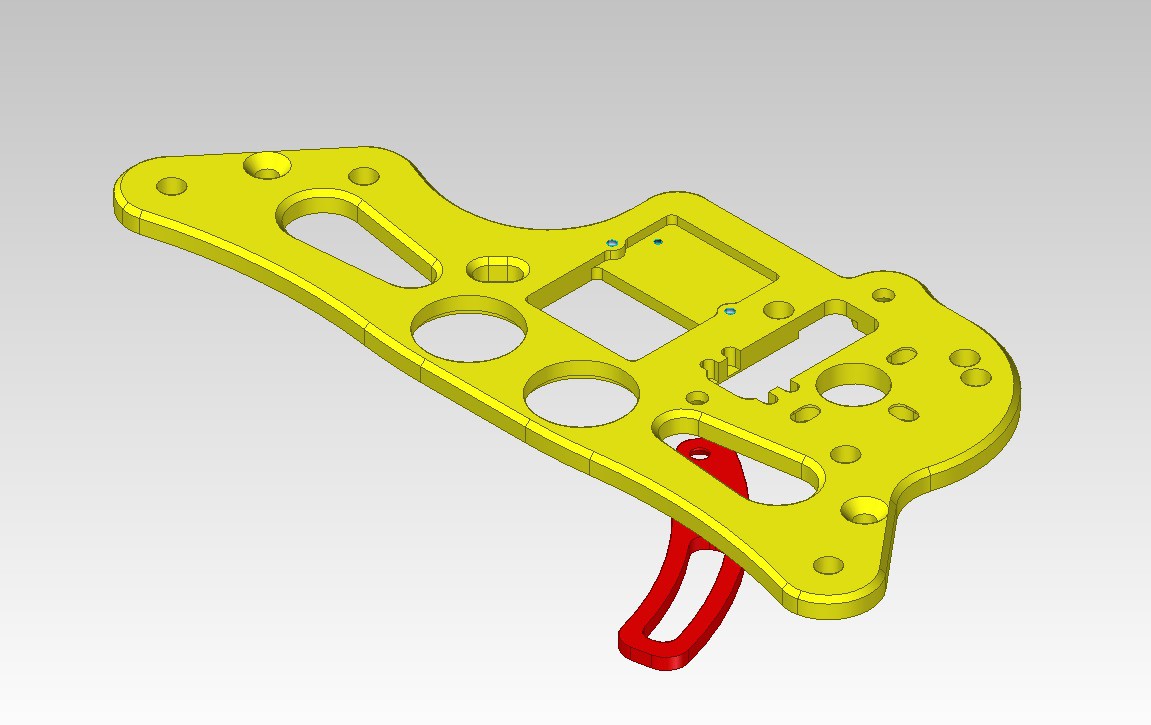

Here is an example of one of the early designs of BikeOn frame:

This frame is made of 2 parts. The top of the frame is chamfered. It is surely nicer looking. But that turned out to be much more expensive than this, final version of the frame:

Now it is made of a single part, can be stamped and then secondary processed, if needed. It is much less expensive and can be made by a shop with very simple machines/tools. That, in turn, allows to diversify the suppliers, build robust supply chain.

Here is another example of such an approach. The rotor of BikeOn is made of 2 identical blanks, as shown here:

Each of the blanks can be machined, but it also can be extruded, further reducing part cost.

Blanks then can be machined to the final shape with pretty minimal machining.

Usage of 2 identical blanks reduces the cost significantly: it is less expensive to order multiple quantities of a single part than half of that quantity of 2 different parts.

It all comes down to the evolution of thinking, which can be developed.

Aram

Aram

Aram

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.