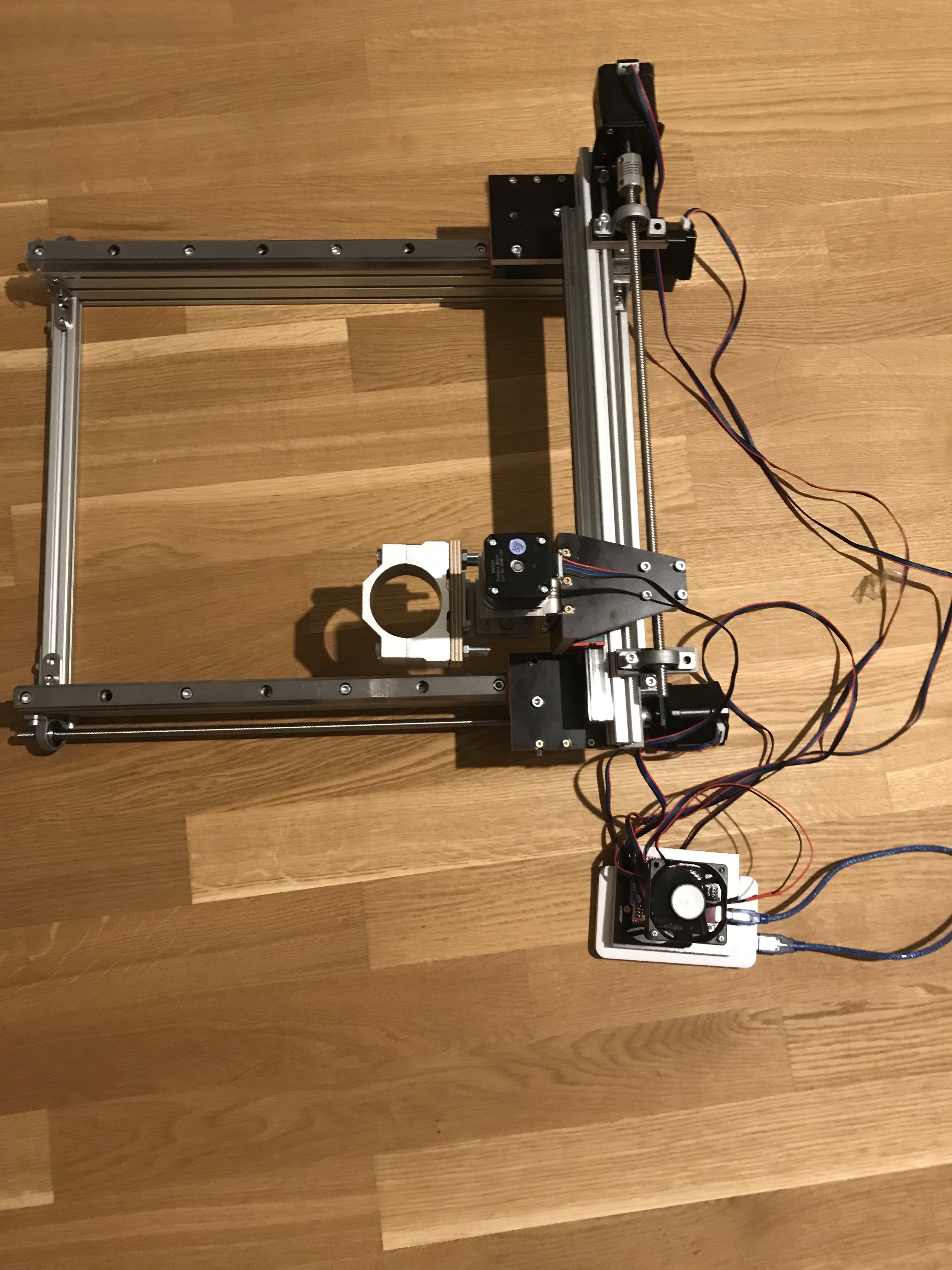

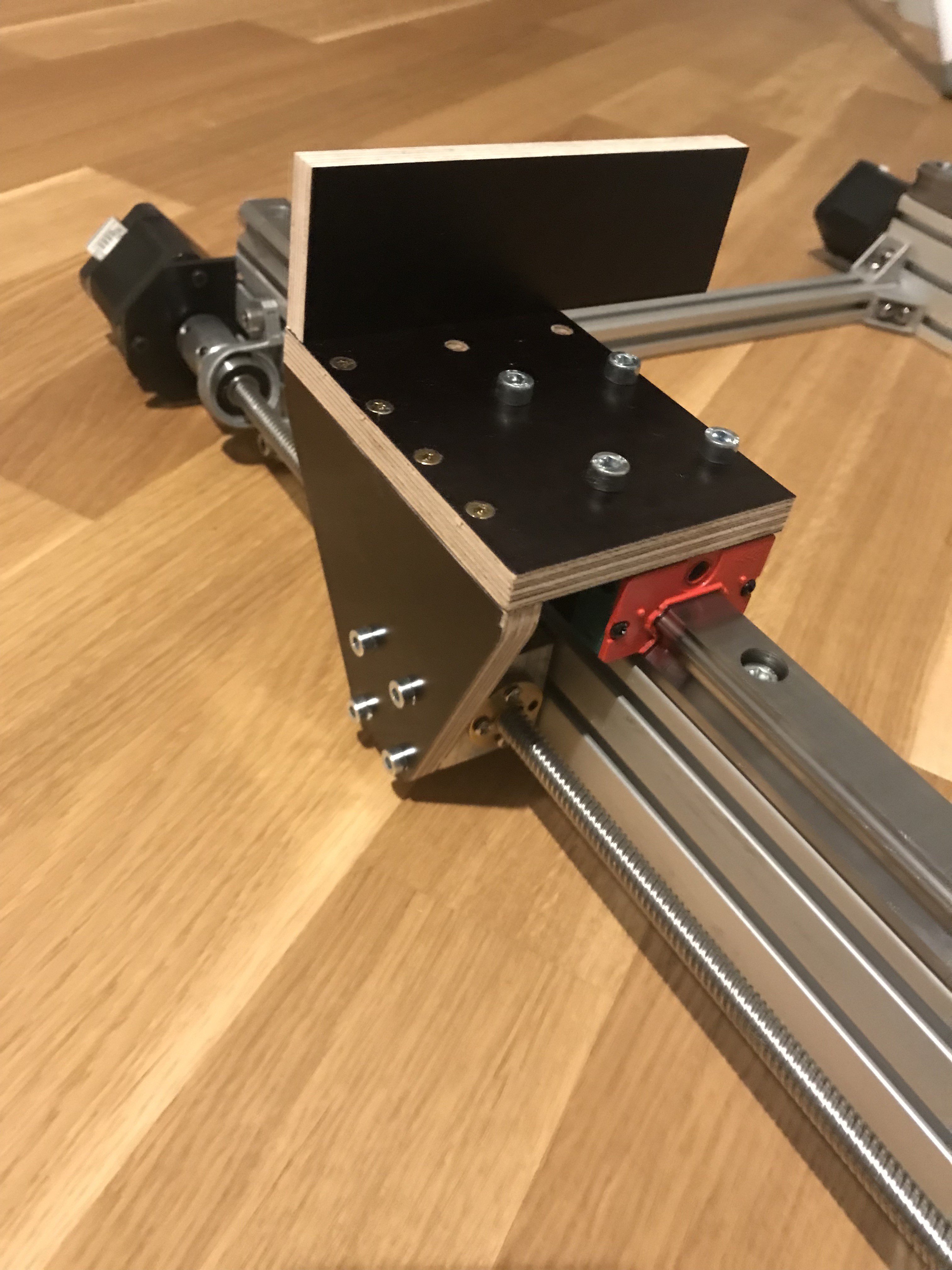

I basically finished the assembly, although there are still some hard points that needs to be solved. The pieces for jointing are square but I missed my measurements in some area by a couple of mm. Making bigger bores for the screws seemed to make it up for the accuracy and this is going the right way overall.

However the Z-axis ready made I bought seems to have a bit of flex in the X direction. I'll see what's the consequence of that when milling and can fix it by attaching the bottom of the sub assembly to the frame with a custom bracket.

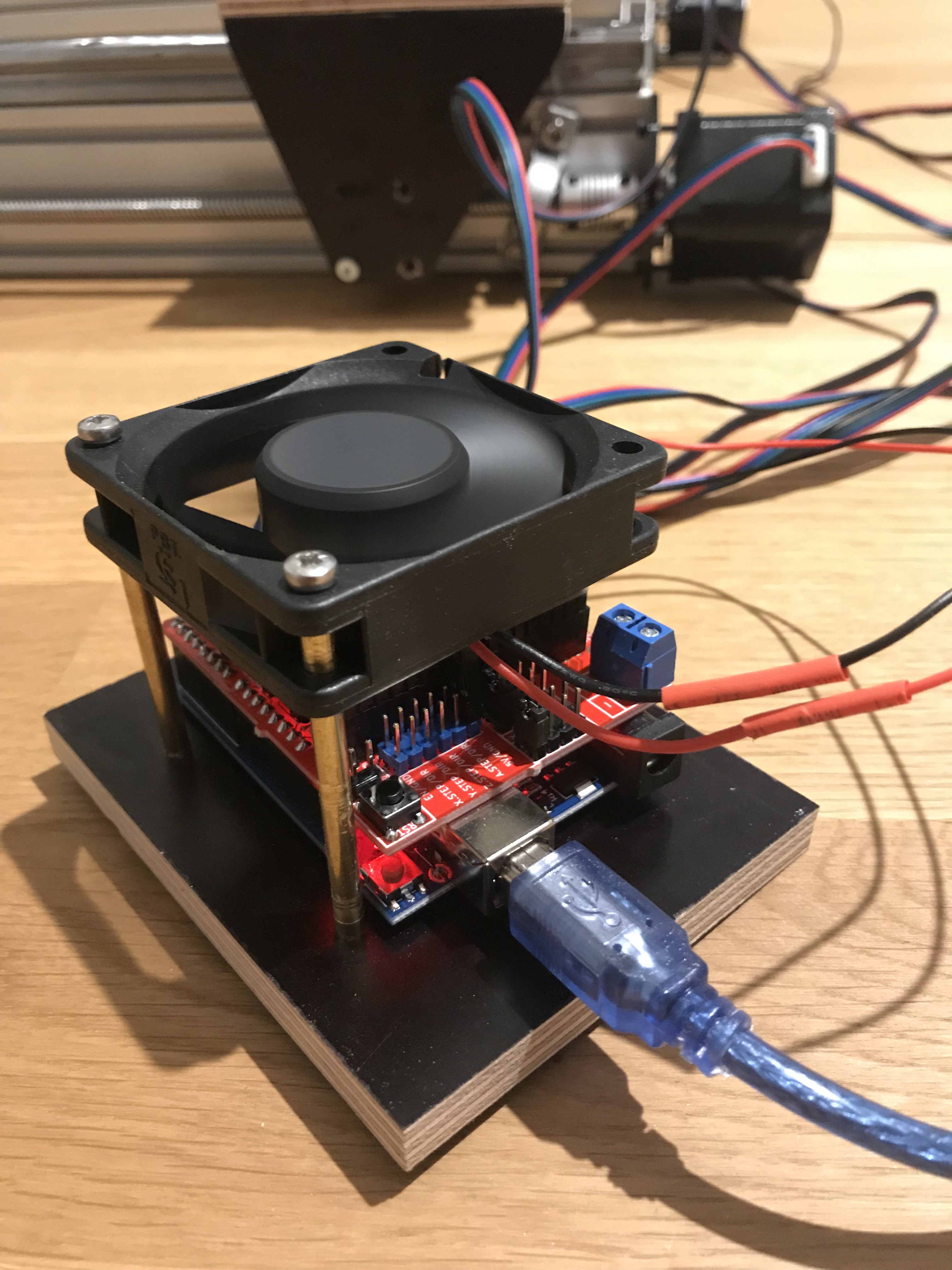

And I added a fan on top of the CNC Shield, self powered by the 5V from the board. This is plenty enough to cool those drivers which are regularly burning my fingers

vincentmakes

vincentmakes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.