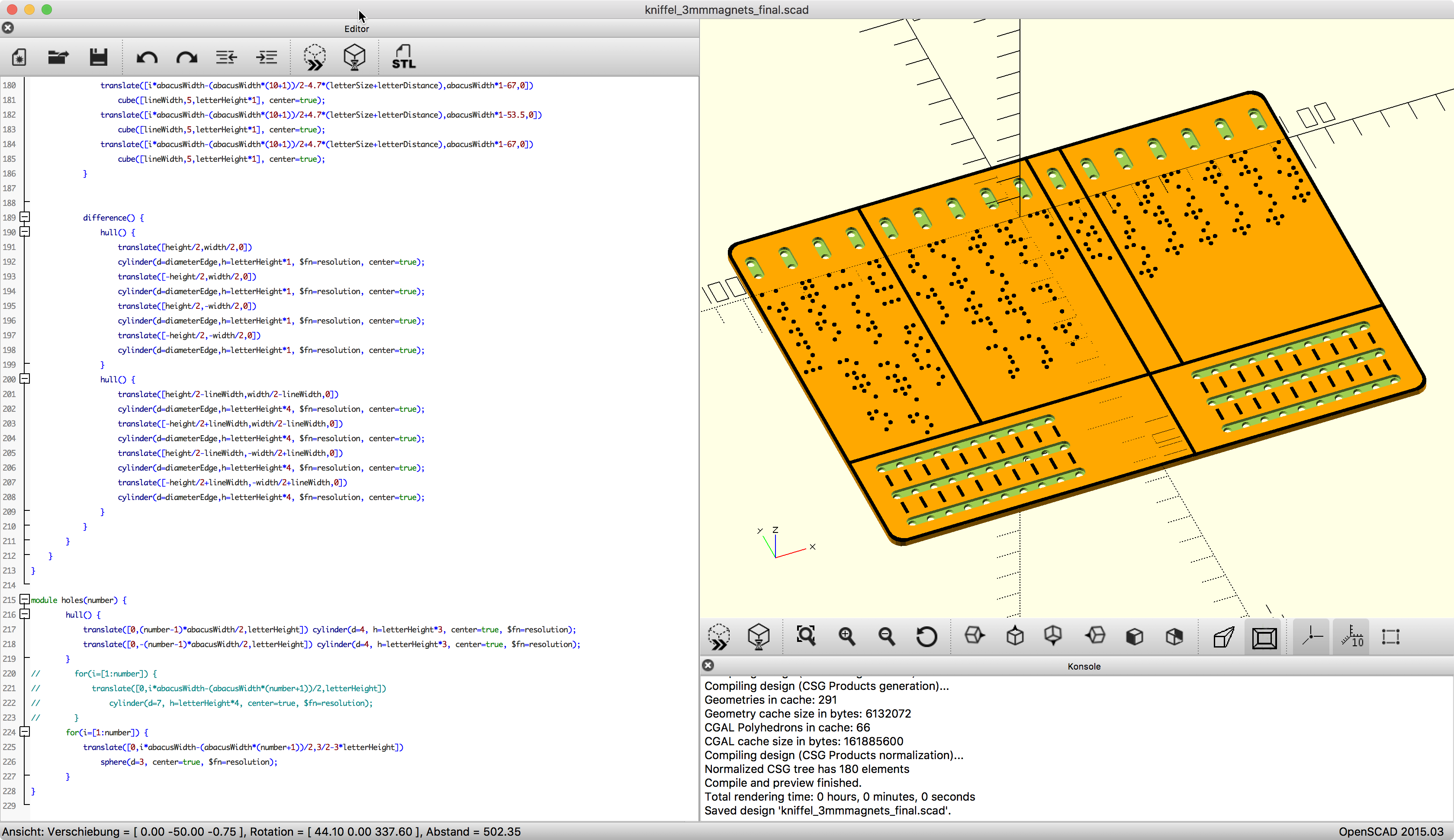

From all the ideas so far the scorecards are the most useful thing (both from the usage as well as production-wise ^^). The biggest problems there is the (minor) problem of the magnets flipping over to another line, which can be reduced by using deeper holes or bigger distances between the checkboxes,abacus rows. The latter will make the card more clumsy, thats why we will go for deeper holes, which will also be used for clearer distingushing of the abacus positions.

While the washer systems gave overall a great locking feature, when the magnets clicks into its hole, some of the washers glueing failed over time, as well as the production process of gluing washers in would be rather expensive (but with reusing common materiels it's of course great for single rebuilding processes as an open-source project). Instead we are now testign the use of a single sheet of metall behind as a base plate. The 3D- cover is then glued on top of it as a single piece, with its form allows even to use the most basic injection molding, thermoforming or casting.

This will furthermore elevetas the issue with the not-fingertip-friendly 3D-printed braille letters, since in this case the right half-sphere form can be used for each dot. For a 3D-printed version it's better to leave the braille letters away and later glue common embossed braille tape with the text on the cards.

Which one need just a (magnetic) sheet (183,7*140) mm, either a magnetic foil or just metal, then a bunch of 3mm magnet spheres and the 3D-printed (or otherwise manufactured) form, glued on top of the magnetic sheet and you are done.

JanThar

JanThar

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.