As given in the project description there is a problem to get spare parts and good accessories for old lathes.

In my case, there is an old Emco Compact 8 in my workshop and I'm not able to buy a good steady rest that fits the lathe. There is a supplier for this steady rest and I bought it. But there were several problem with it. (1) it didn't fit perfectly. The center of the steady rest where the workpiece should be centered was offcenter by about 5-10mm. Thus, the workpiece could not be supported very well. (2) the carriage of the lathe could not pass the steady rest, since the the width of the steady rest bottom part is to large (by about 1mm) and (3) this product for about 144€ excl. shipping.

There are many ways to create a steady rest for your lathe. A very sturdy steady rest is created by "Make it extreme" Youtube channel. They documented the process in a video. But to build the steady rest and adapt it to your needs, welding equipment, a band saw and other stuff is required. Although the plans are online, you have to pay for it to subscribe to patreons. Another very different steady rest project has been created by Curtis Hajek. In contrast to the steel steady rest of "Make it extreme", Curtis builds one using wood. So, in my opinion, it cannot be very sturdy. "Soat Mon" Youtube channel documented another process creating a steady rest. It seems to be a very good steady rest, but it may require to cast aluminium.

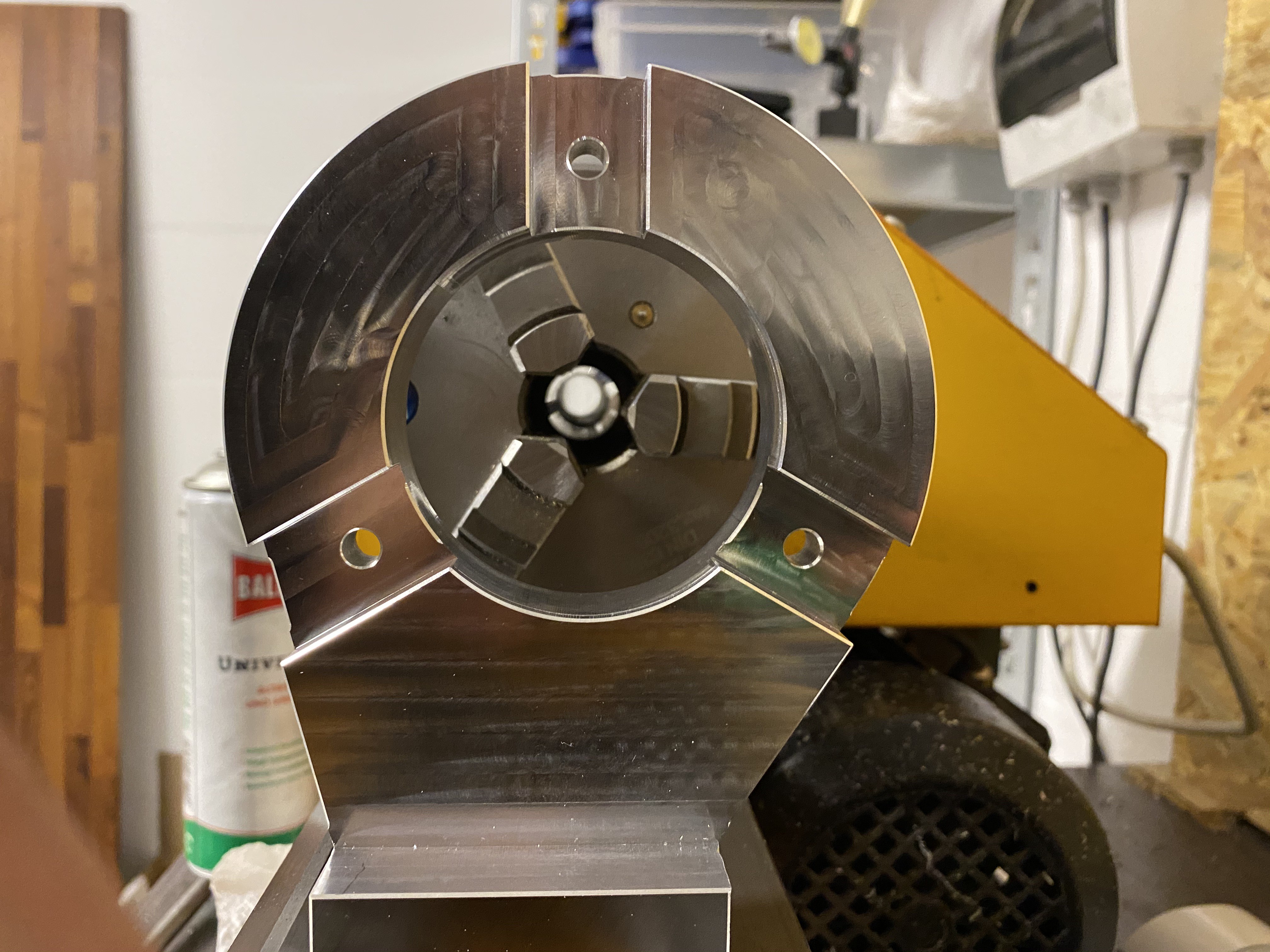

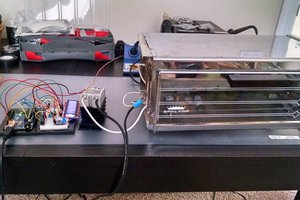

In this project, we create a steady rest from a block of aluminium for the steady rest and some flat brass for the moveable parts. Using a CNC milling machine, the steady rest is carved out of the aluminium block. The same machine is used to create the moveable parts out of the flat brass.

Of course, not everyone has access to a CNC milling machine, but since the plans are published here, everyone can order it from a machine shop.

I'm a maker

I'm a maker

Bobby Christopher

Bobby Christopher

artbyphysicistkitty

artbyphysicistkitty

Peter Victoratos

Peter Victoratos

Frank Vigilante

Frank Vigilante